A thread forming tool

A thread and cutting tool technology, applied in the field of threads used to form internal threads in metal workpieces, can solve problems such as high temperature, achieve uniform wear distribution, reduce wear, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

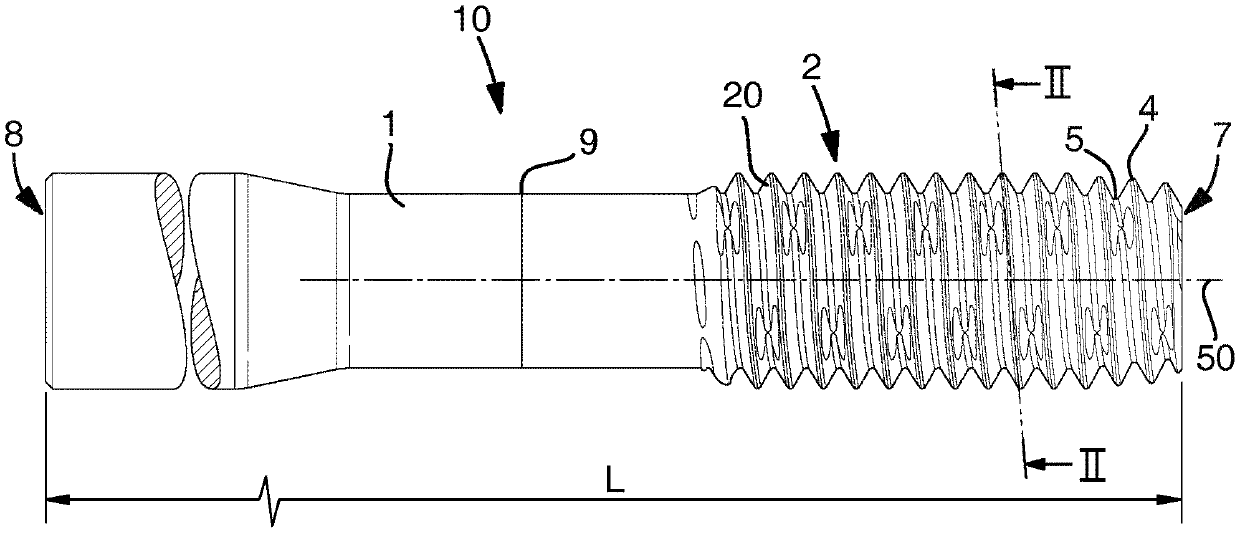

[0029] refer to figure 1 , figure 1 A side view of a thread forming tool 10 for forming an internal thread in a metal workpiece, ie for creating a thread in a hole without any material removal action, is shown in a side view according to a first embodiment. The thread forming tool 10 comprises a shank 1 and a thread forming part 2 , which are rotatable about a common axis 50 . The axis 50 extends in the longitudinal direction of the thread forming tool 10 . The shank 1 is arranged at the rear of the thread forming tool 10 and the thread forming part 2 is arranged at the front of the thread forming tool 10 . The thread forming tool has a front end 7 and a rear end 8 , the distance between which in the longitudinal direction is the full length L of the thread forming tool 10 . The thread forming part 2 is fixedly connected to the handle 1 . More specifically, the thread forming portion 2 and the handle 1 are made in a single piece of material. The thread forming tool 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com