Method for regulating an internal combustion engine for supercharging

An adjustment method and internal combustion engine technology, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve problems such as efficiency needs to be improved, compressor surge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

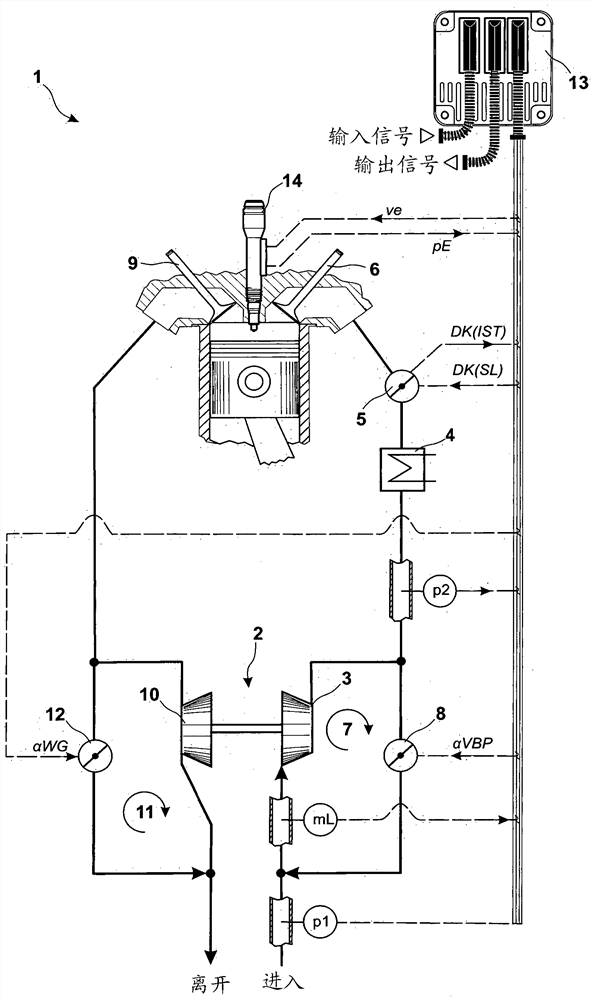

[0015] figure 1 A simplified system diagram of an internal combustion engine 1 with an exhaust gas turbocharger 2 is shown. The exhaust gas turbocharger 2 includes a compressor 3 and a turbine 10 . The further design and function of exhaust gas turbocharger 2 are assumed to be known. The air path for supplying combustion air comprises a compressor 3 , a charge air cooler 4 , a throttle valve 5 and an intake valve 6 in the cylinder head of the internal combustion engine 1 . The air path is supplemented by a compressor bypass 7 with a compressor bypass valve 8 . Charge air is conducted from the secondary side of the compressor 3 back to the primary side of the compressor 3 via the compressor bypass 7 . The exhaust path includes exhaust valves 9 in the cylinder heads of the internal combustion engine 1 and the turbine 10 . The exhaust gas path is supplemented by a turbine bypass 11 with a turbine bypass valve 12 .

[0016] Internal combustion engine 1 is controlled and regul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com