A suit jacket manufacturing process

A production process and technology for suits, applied in the field of suit jacket production technology, can solve the problems of complex processing technology, affecting the beauty of suits, deformation and wrinkles, etc., to ensure cleanliness, enhance stiffness and three-dimensional sense, and reduce wrinkles. possible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: a kind of suit jacket manufacturing process, comprises the following steps:

[0056] (1) Fabric treatment: place the fabric on the workbench and use a brush to clean the broken threads and dust on the fabric, then level the fabric and relax naturally for 36-60 hours.

[0057] (2) Cutting and molding: After laying the fabric flat, position it with needles, and cut it at a uniform speed according to the template.

[0058] (3) Sewing the body: Sew the corresponding fabric on the torso of the suit. When sewing, iron while sewing.

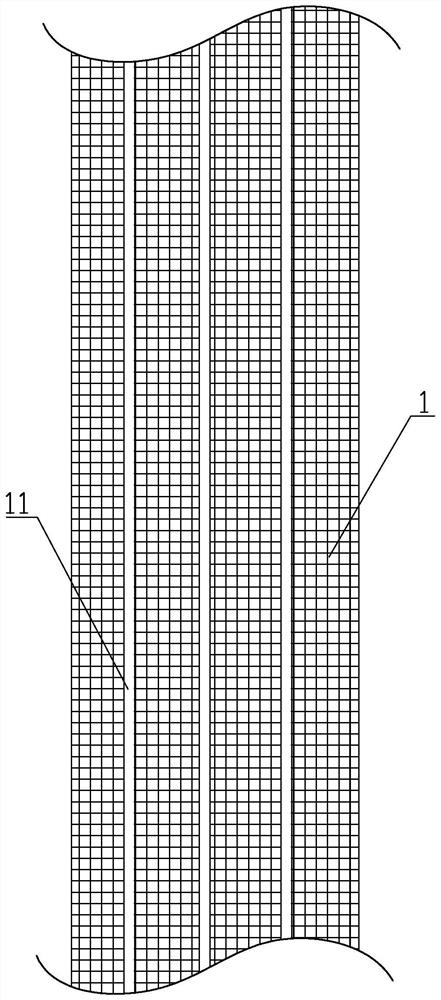

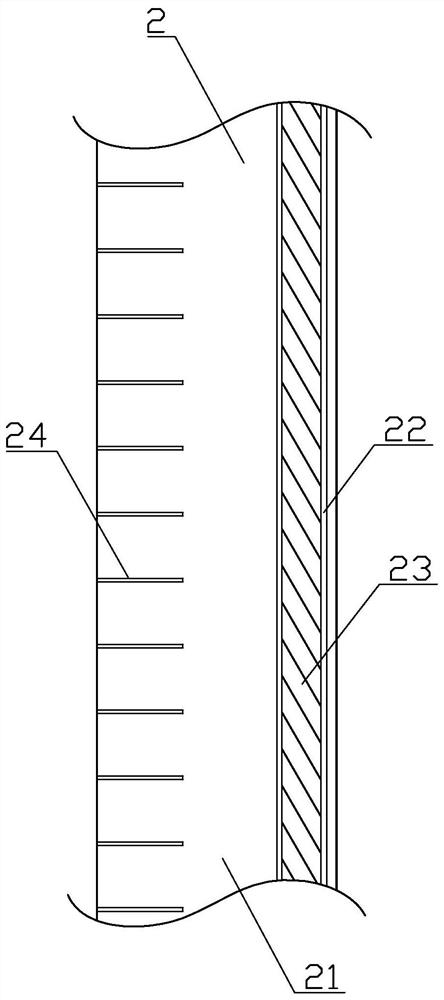

[0059] (4) Shoulder seams: 1cm straight silk insert 1 is printed and glued on the front neckline, lapel, lapel and splits according to the net line (see figure 1 ), back neckline adhesive lining 1cm mother-in-law molding 2 (see figure 2 ). When bonding the lining, the temperature of the lining machine is set between 120-135 degrees Celsius, and the pressure of the lining machine is set at 3-3.6kg / cm^2, so as to achieve the purpose...

Embodiment 2

[0075] Embodiment 2: as figure 1 As shown, a suit jacket manufacturing process, the difference between this embodiment and embodiment 1 is that the marking line 11 in step (4) uses luminous fiber. The luminous fiber is made of cotton fiber dyed with fluorescent liquid, which has the function of luminescence after being illuminated, and can provide good resolution in a dark environment, so that the operator can control the sewing position and improve the sewing accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com