A method of wire-cutting artificial diamond wire drawing die

A technology of artificial diamond and wire drawing dies, which is applied in metal wire drawing, manufacturing tools, metal processing equipment, etc., can solve the problems of low processing efficiency, large hole shape deviation, large fluctuation of height, angle, shape, etc., and achieve high production efficiency , long service life and consistent hole structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

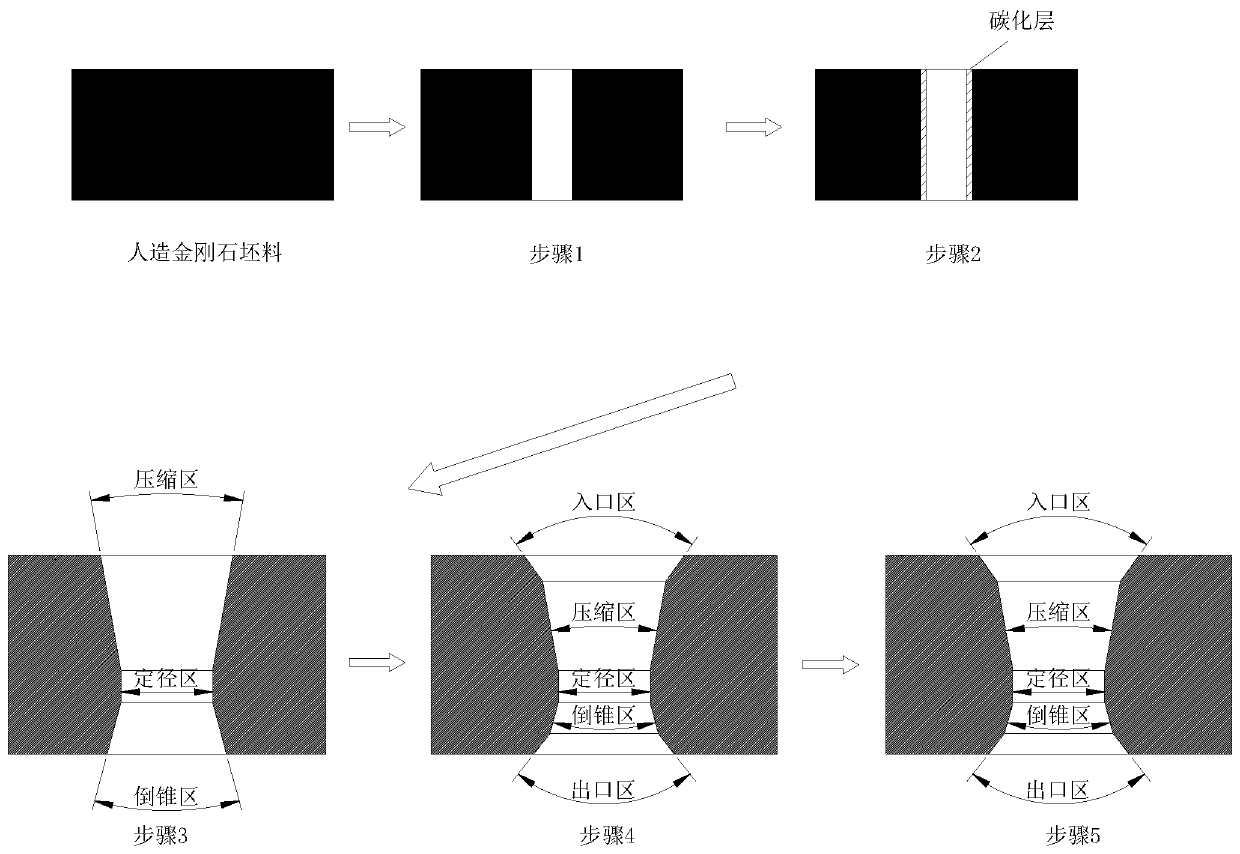

[0020] Step 1, using a laser machine to perforate the artificial diamond blank, the diameter of the obtained laser hole is 0.2mm larger than the diameter of the wire cutting wire used for wire cutting;

[0021] Step 2, using a thin steel wire coated with oil-tuned diamond powder to pass through the laser hole, and then grinding the laser hole through the thin steel wire to remove the carbonized layer inside the laser hole due to laser perforation. Grinding refers to the relative movement between the thin steel wire and the laser hole, and the grinding time is about 2 minutes. The oil-adjusted diamond fine powder is blended with low-viscosity transformer oil to form 5# diamond fine powder, and a stable mixture is formed by stirring.

[0022] Step 3, fixing the synthetic diamond blank on the working table of the wire cutting machine, performing wire cutting on the inner side of the laser hole according to the processing program set in the wire cutting machine to obtain an inner ...

Embodiment 2

[0032] Step 1, using a laser machine to perforate the artificial diamond blank, the diameter of the obtained laser hole is 0.3mm larger than the diameter of the wire cutting wire used for wire cutting;

[0033] Step 2, using a thin steel wire coated with oil-tuned diamond powder to pass through the laser hole, and then grinding the laser hole through the thin steel wire to remove the carbonized layer inside the laser hole due to laser perforation. Grinding refers to the relative movement between the thin steel wire and the laser hole, and the grinding time is about 3 minutes.

[0034] Step 3, fixing the synthetic diamond blank on the working table of the wire cutting machine, performing wire cutting on the inner side of the laser hole according to the processing program set in the wire cutting machine to obtain an inner hole with a preliminary hole structure.

[0035] During the wire cutting process, the wire cutting wire passes through the laser hole, and the wire cutting wir...

Embodiment 3

[0043]Step 1, using a laser machine to perforate the artificial diamond blank, the diameter of the obtained laser hole is 0.4mm larger than the diameter of the wire cutting wire used for wire cutting;

[0044] Step 2, using a thin steel wire coated with oil-tuned diamond powder to pass through the laser hole, and then grinding the laser hole through the thin steel wire to remove the carbonized layer inside the laser hole due to laser perforation. Grinding refers to the relative movement between the thin steel wire and the laser hole, and the grinding time is about 3 minutes.

[0045] Step 3, fixing the synthetic diamond blank on the working table of the wire cutting machine, performing wire cutting on the inner side of the laser hole according to the processing program set in the wire cutting machine to obtain an inner hole with a preliminary hole structure.

[0046] During the wire cutting process, the wire cutting wire passes through the laser hole, and the wire cutting wire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com