A self-adaptive fixture for pipeline welding

A tooling fixture and self-adaptive technology, applied in welding equipment, manufacturing tools, auxiliary welding equipment, etc., can solve the problems of inability to accurately adjust the welding angle of the pipeline, unstable fixing of the pipeline shell, troublesome adjustment of the welding fixture, etc., and achieve easy promotion Use, innovative design, and the effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

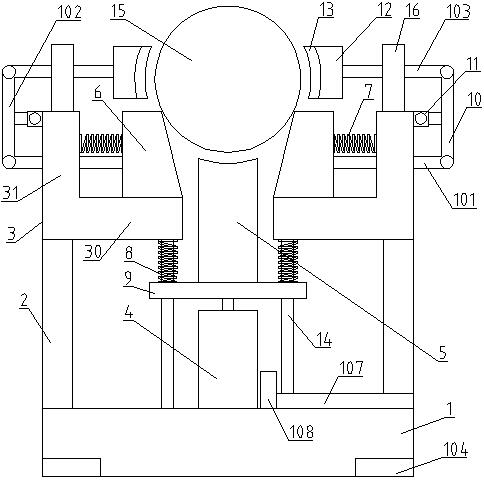

[0033] Such as figure 1 As shown, a pipeline welding self-adaptive fixture of the present invention includes a base 1, a support column 2 and an installation block 3, the support column 2 is arranged at both ends of the base 1, and the installation block 3 is arranged on the support column 2, and the installation A support space is provided between the blocks 3, and a jack post 5 for placing the pipeline 15 is arranged in the support space, and an oil cylinder 4 is arranged on the base 1, and the jack post 5 is connected to the top shaft of the oil cylinder 4 through a guide mechanism; the setting of the guide mechanism It can effectively guide the movement direction of the top column 5, avoid misalignment, and ensure precise operation during movement. The lifting and lowering of the jacking column 5 is realized by the telescoping of the jacking shaft of the oil cylinder 4 so as to realize the lifting and lowering of the pipeline 15 .

[0034] The mounting block 3 includes a ...

Embodiment 2

[0042] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the longitudinal corner block 31 also includes a support block 16 arranged on its top, and the clamping section 103 slides through the support block 16 and the locking sleeve 161 on the support block 16 set on the support block 16. The outer diameter of the locking sleeve 161 shrinks away from the support block 16. The locking sleeve 161 is provided with a number of scaling grooves 163 that facilitate the scaling of the locking sleeve 161. The locking sleeve 161 is threadedly connected with a compression ring. 162.

[0043] In use, when the pipe is clamped and the pressure ring 162 is twisted, the pressure of the pressure ring 162 on the locking sleeve 161 gradually increases due to the diameter change of the locking sleeve 161 . At the same time, the positive pressure of the locking sleeve 161 on the clamping section 103 also increases, and the relative friction between the lo...

Embodiment 3

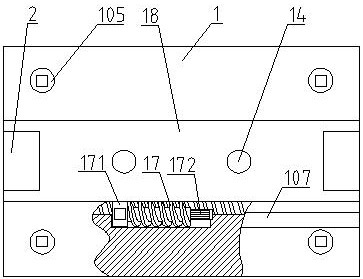

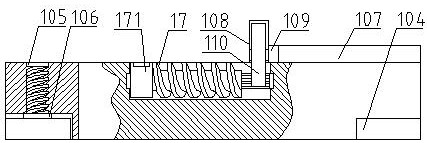

[0045] Such as figure 2 with 3 As shown, the base 1 also includes support legs 104, worm 17, sliding base 18 and adjustment cylinder 107; The guide rod 14 is arranged on the sliding base 18 , and the adjusting cylinder 107 is arranged on the base 1 parallel to the sliding base 18 .

[0046] One end of the adjustment cylinder 107 is connected with the gear cover 108 on the base 1 , and the adjustment cylinder 107 is provided with an adjustment ball 109 connected with the driving gear 110 , and the driving gear 110 is arranged in the gear cover 108 .

[0047] The worm 17 is arranged in the base 1 and connected with the sliding base 18; one end of the worm 17 is connected with the adjusting collar 171 through a ratchet, and the other end is provided with a driven gear 172 with a smaller diameter, and the driven gear 172 cooperates with the driving gear 110 connect.

[0048] An adjusting screw 105 is connected to the supporting leg 104 , the adjusting screw 105 passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com