A method for removing an upper structure of an overwater thin-cable system cable-stayed bridge

A technology for cable-stayed bridges and thinning cables, which is applied in the field of dismantling the superstructure of cable-stayed bridges with thinning cables on water, can solve the problems of inconsistent grade requirements, long erection period, and interruption of navigation, etc., so as to improve demolition efficiency, ensure safety, The effect of reducing the time spent on the course

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

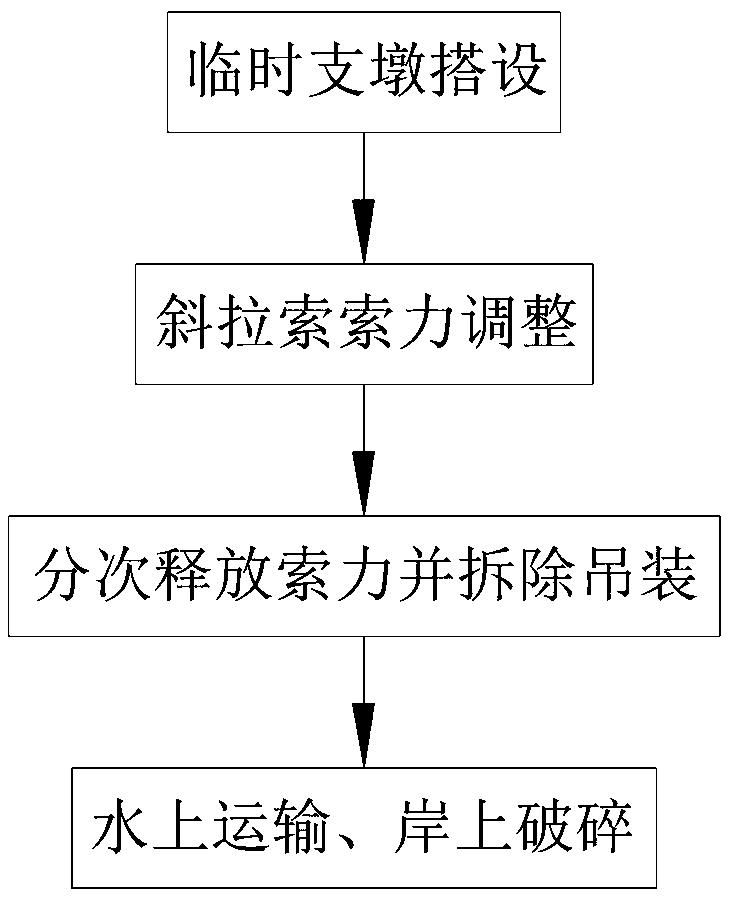

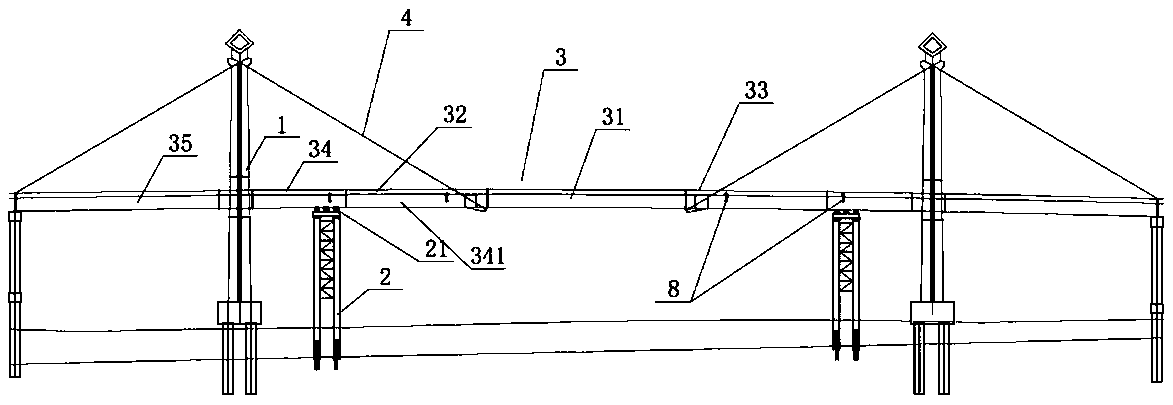

[0027] Such as Figure 1 to Figure 4 As shown, the method for dismantling the upper structure of the cable-stayed bridge with thin cable system on the water of the present embodiment comprises the following steps:

[0028] S1: Erection of temporary buttresses: set up temporary buttresses 2 near the main tower 1, so that the temporary buttresses 2 are supported under the solid section of the main girder 3 of the bridge body;

[0029] S2: Stay cable force adjustment: remove a bundle of stay cables 4 on the side span side, adjust the cable force, and keep the cable force of stay cables 4 on both sides of the main tower 1 symmetrically balanced;

[0030] S3: Release the cable forces in stages and remove the hoisting: symmetrically release the first and second cable forces, remove the hanging beam 31 and use a large floating crane 5 to ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com