Vertical glass door energy saving low temperature cabinet

A technology for glass doors and low-temperature cabinets, which is applied to coolers, damage protection, lighting and heating equipment, etc. It can solve problems such as temperature imbalance, large power consumption, and poor drainage in the cabinet, and reduce external wind interference , small power loss, full defrosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

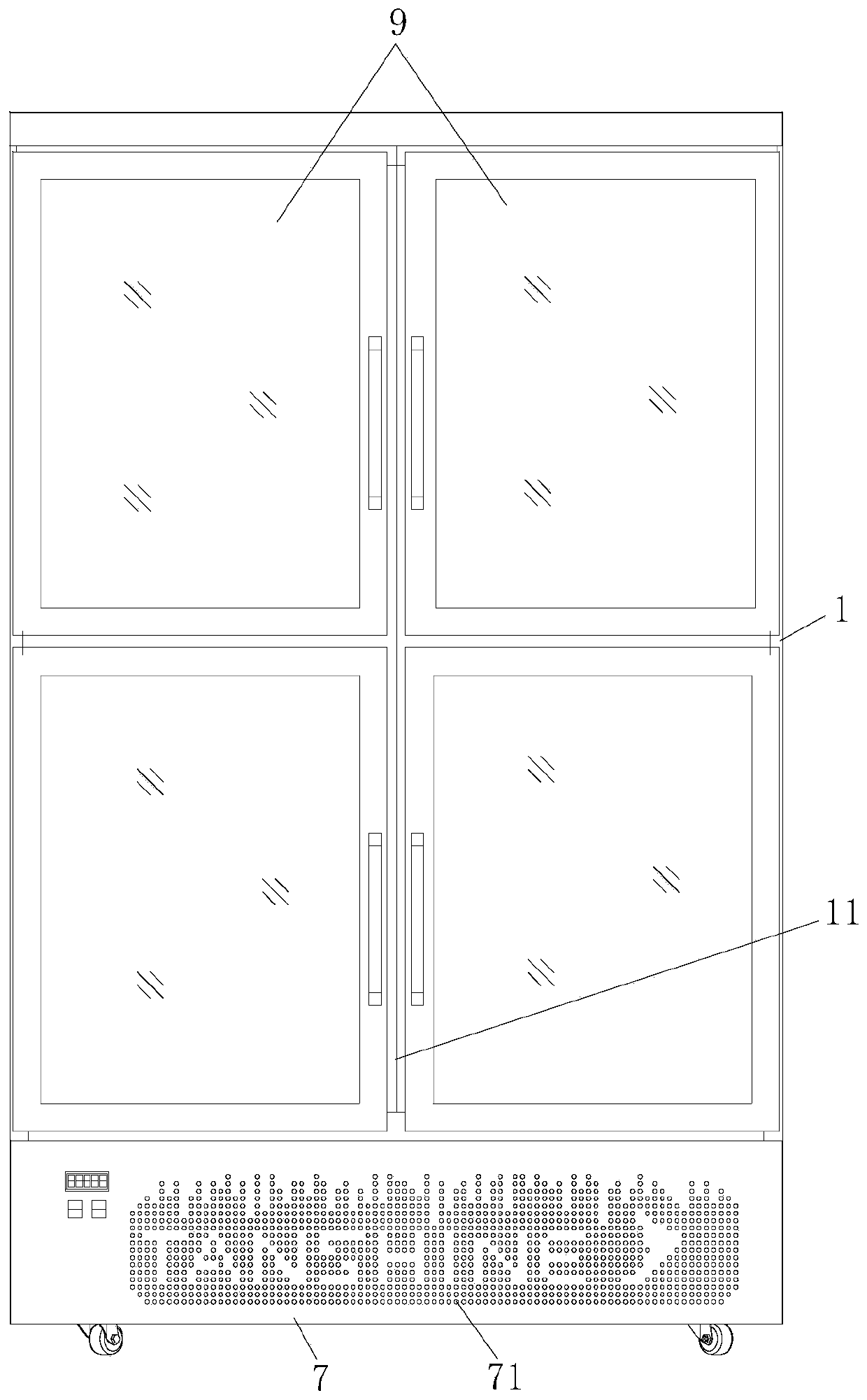

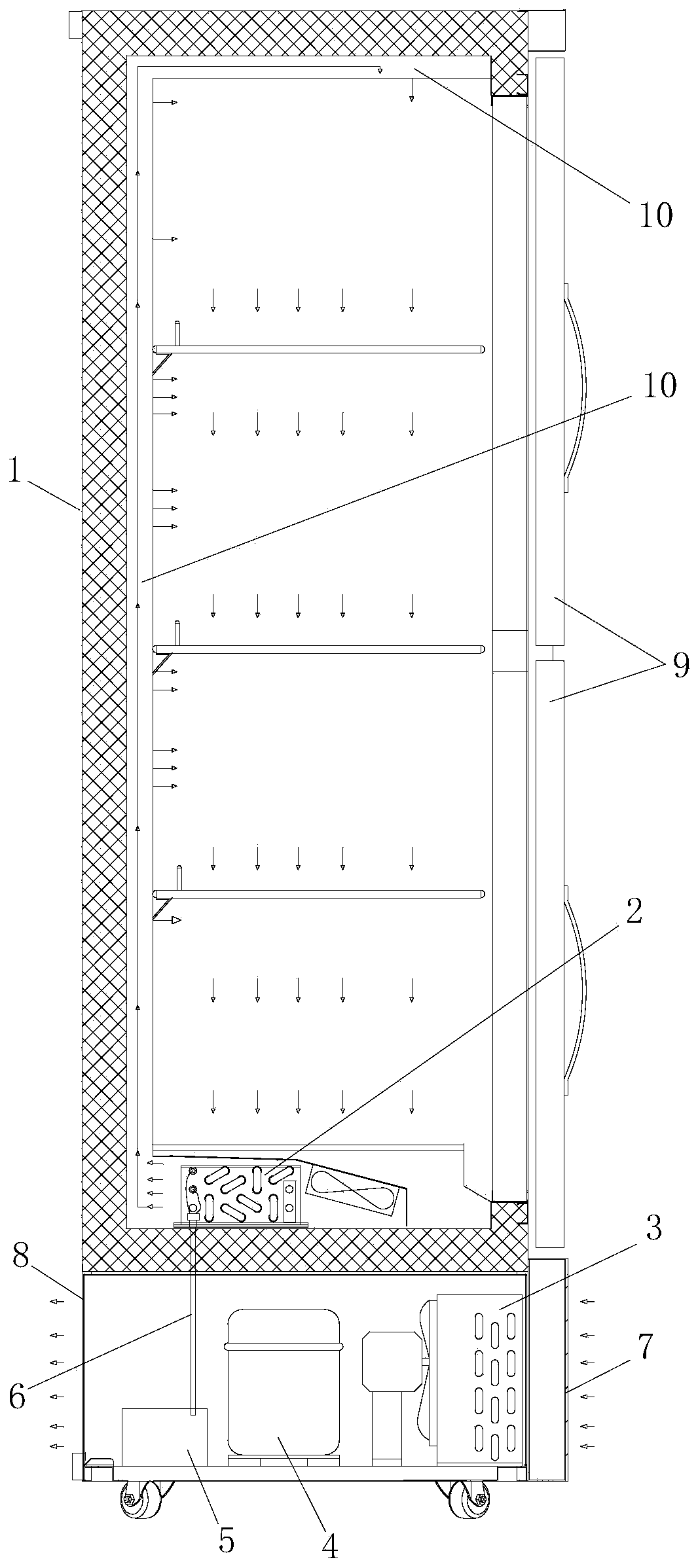

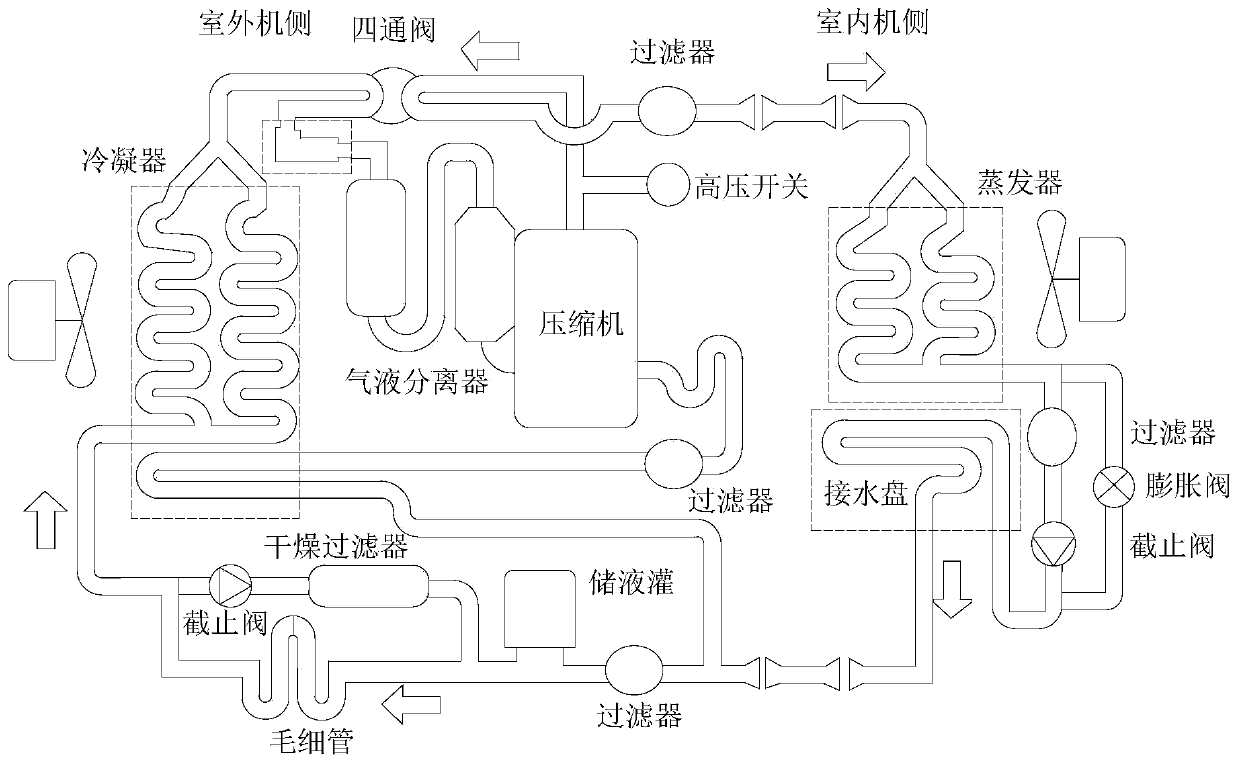

[0015] In this example, refer to figure 1 , figure 2 and image 3 , the vertical glass door energy-saving low-temperature cabinet includes a body 1, a refrigeration cycle mechanism is arranged in the body 1, and a cabinet door 9 is arranged on the body 1; the refrigeration cycle mechanism includes an evaporator 2, a condenser 3, and a compressor 4 And the gas-liquid separator; the condenser 3 and the compressor 4 are arranged at the bottom of the body 1, and both are in the same space, the condenser 3 is in front, the compressor 4 is behind, and the front of the condenser 3 is provided with an air inlet The air intake plate 7 with holes 71 forms the front bottom air intake structure, and the rear of the compressor 4 is provided with a heat dissipation plate 8 full of heat dissipation holes; At the same time, the evaporator 2 is also located below the storage room, and the space where the evaporator 2 is located is isolated from the space where the condenser 3 and the compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com