Pressure measuring element

A load cell, sensor unit technology, applied in measuring devices, weighing equipment using elastically deformable parts, instruments, etc. Product life and the effect of improving product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the present invention will be described with reference to the drawings as follows.

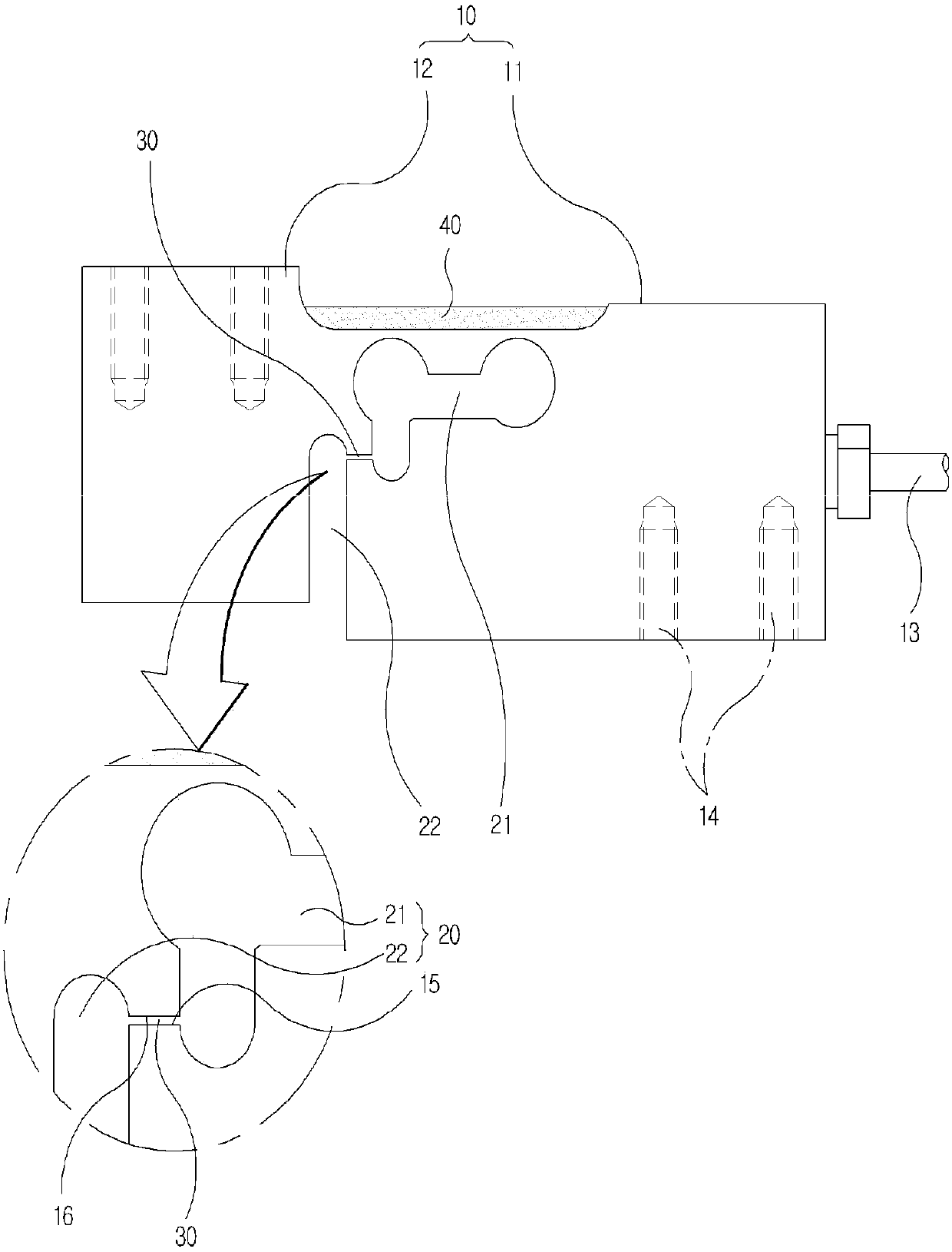

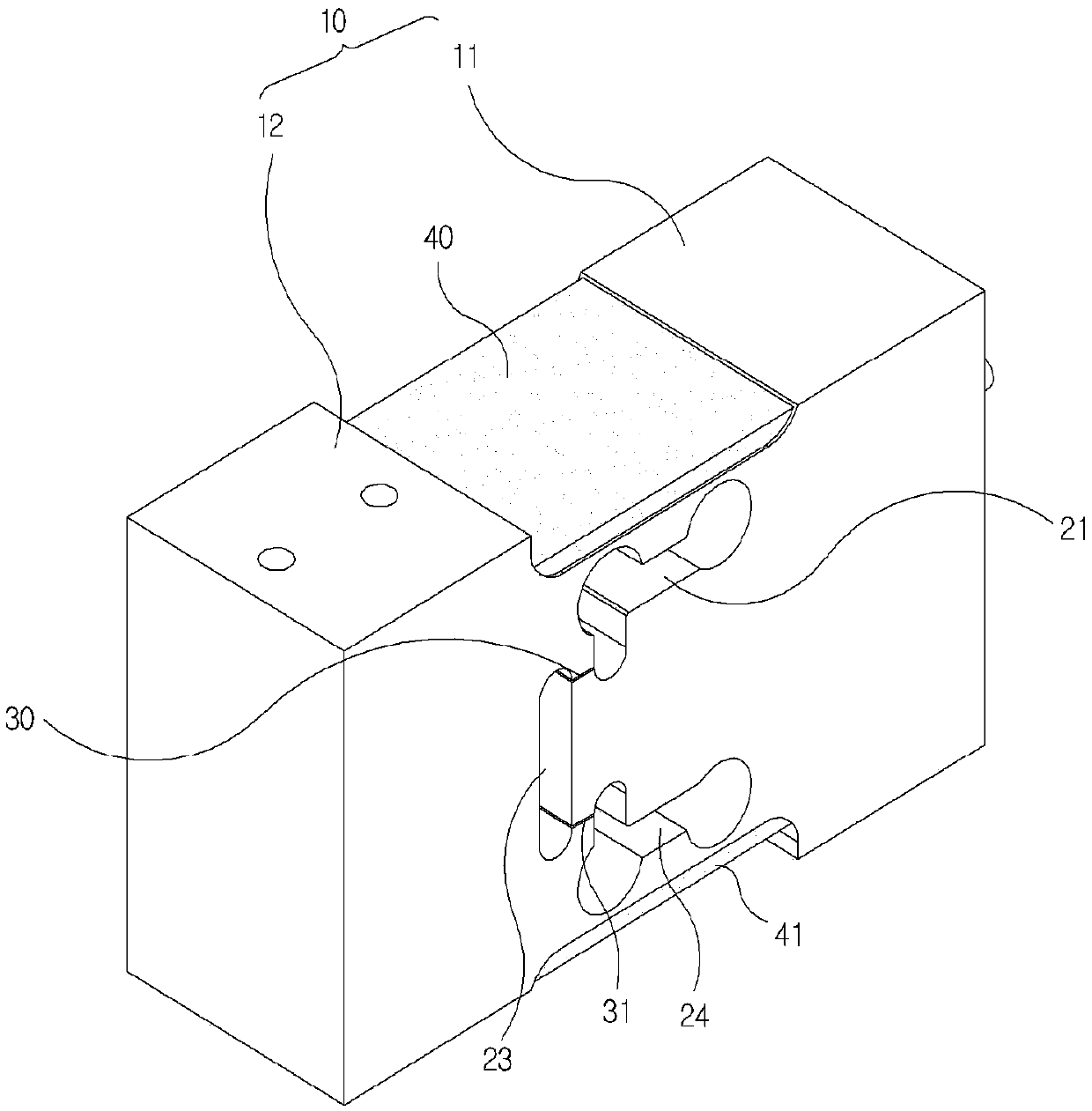

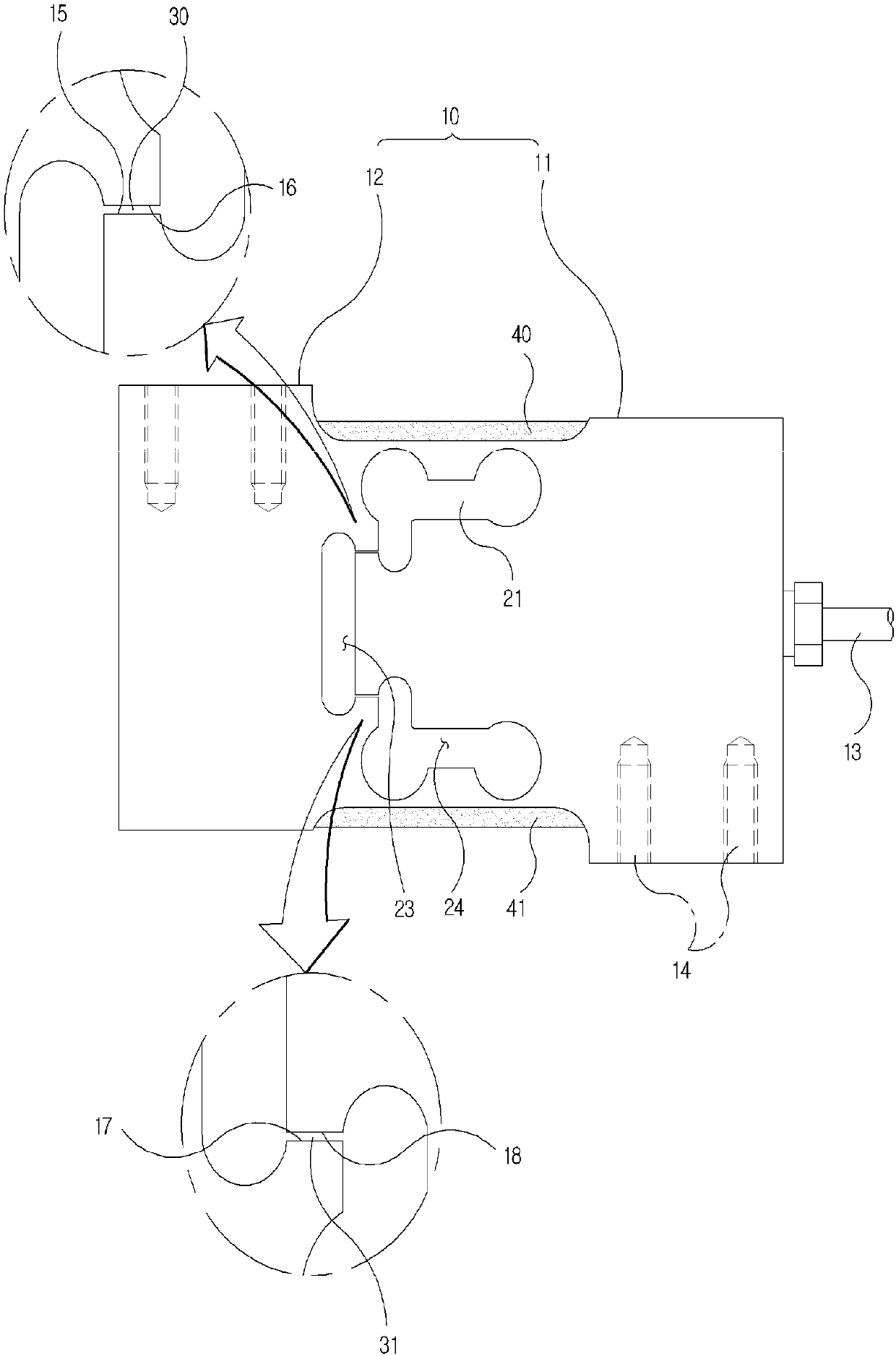

[0028] like figure 1 As shown, the load cell according to an embodiment of the present invention includes a housing 10 , a plurality of through portions 20 , a first slit portion 30 and a first sensor unit 40 .

[0029] The housing 10 is in the shape of a rectangular block and includes a first housing part 11 and a second housing part 12. The bottom surface of the first housing part 11 is flat so as to be closely fixed to the ground, and the second housing part 12 It is integrally connected with the first shell part 11 , and flows down to a certain height according to downward pressure, and rises to the original state when the pressure is released.

[0030] Wherein, the bottom surface of the second shell part 12 has a structure separated from the ground by a certain height, so as to be able to flow up and down to a certain height. A placement plate for placing a measureme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com