Processing equipment for potato food production

A technology for processing equipment and potatoes, applied in the field of processing equipment for potato food production, can solve the problems of low efficiency and poor coherence of mashed potatoes, and achieve the effects of novel structure, improved efficiency and strong coherence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

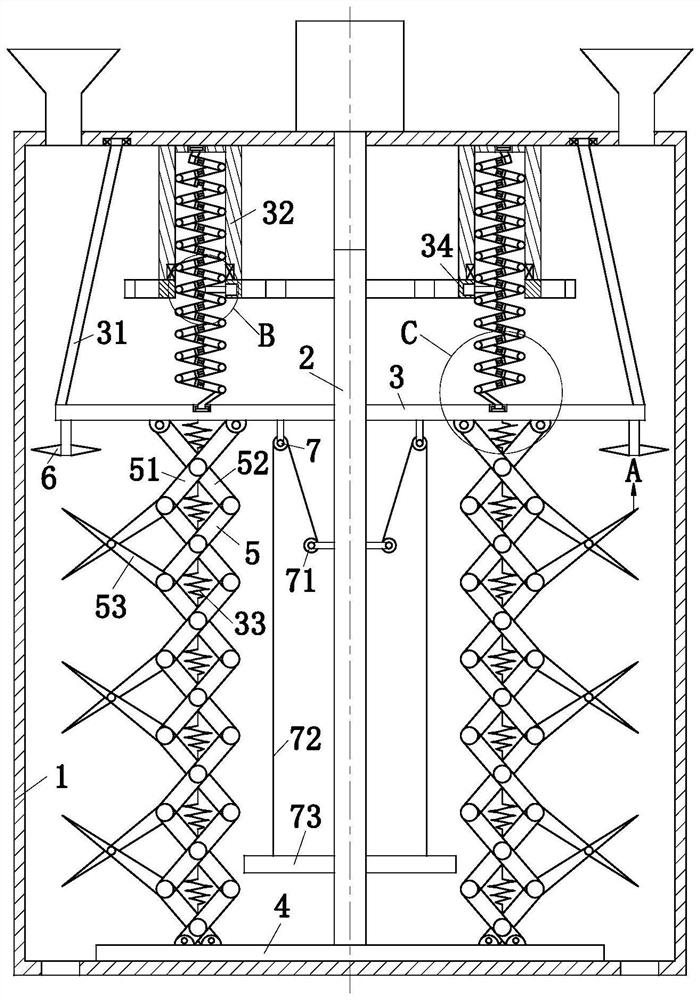

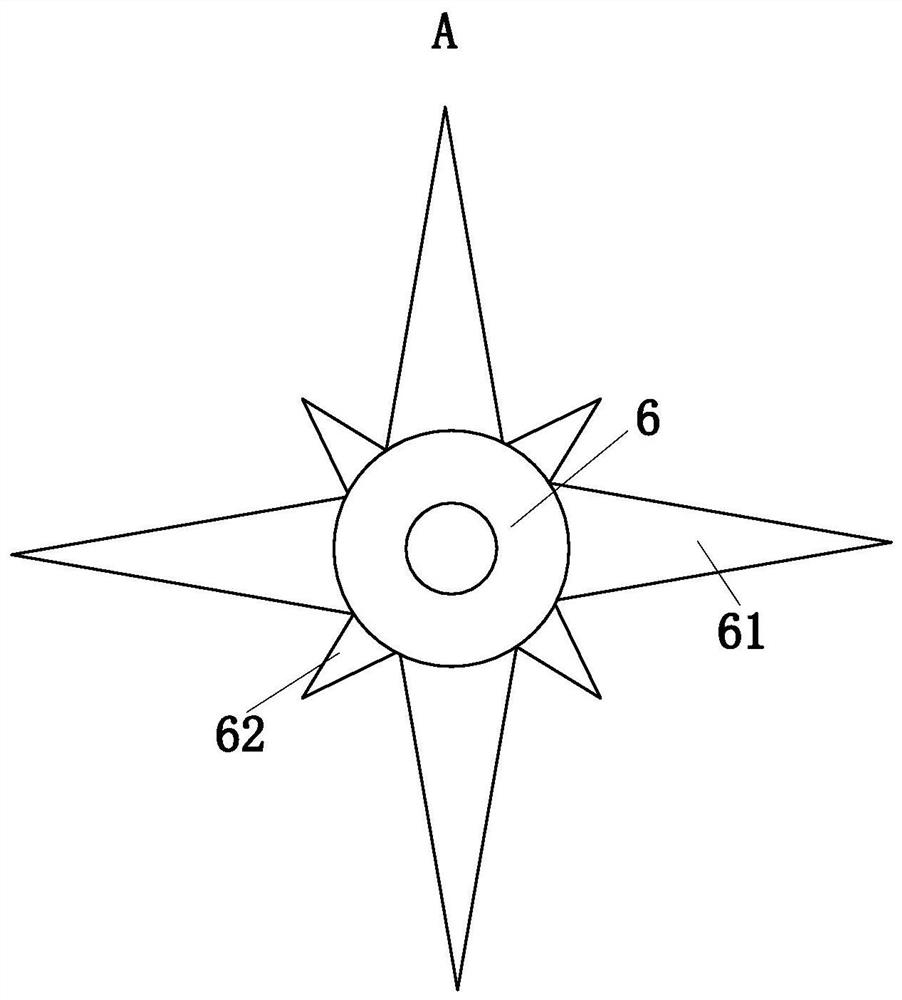

[0025] As a specific embodiment of the present invention, a rotary knife 6 is provided below the end portion of the one-turning plate, and the rotary knife 6 is fixed by the knife holder, and the rotary knife 6 is from the first tie 61 and The second rotary knife 62 is composed, and the length of the No. 1 rotary knife 61 is greater than the length of the second rotary knife 62; the rotary knife 6 is used to perform preliminary chipping potatoes; the present invention is provided by a rotary knife 6, a rotary knife 6 Preliminary chopping of potatoes, shortening the time of mashed potatoes, and by using a number of tweets 61 and the second rotor 62 having different lengths, the size of the potato can be preliminarily chopped, and the equipment is improved. Applicable range.

[0026] As a specific embodiment of the present invention, the shears 54 composed of the No. 1 rod 51 and the second rod 52 are provided with a second spring 54, and the second spring 54 is a hollow structure, ...

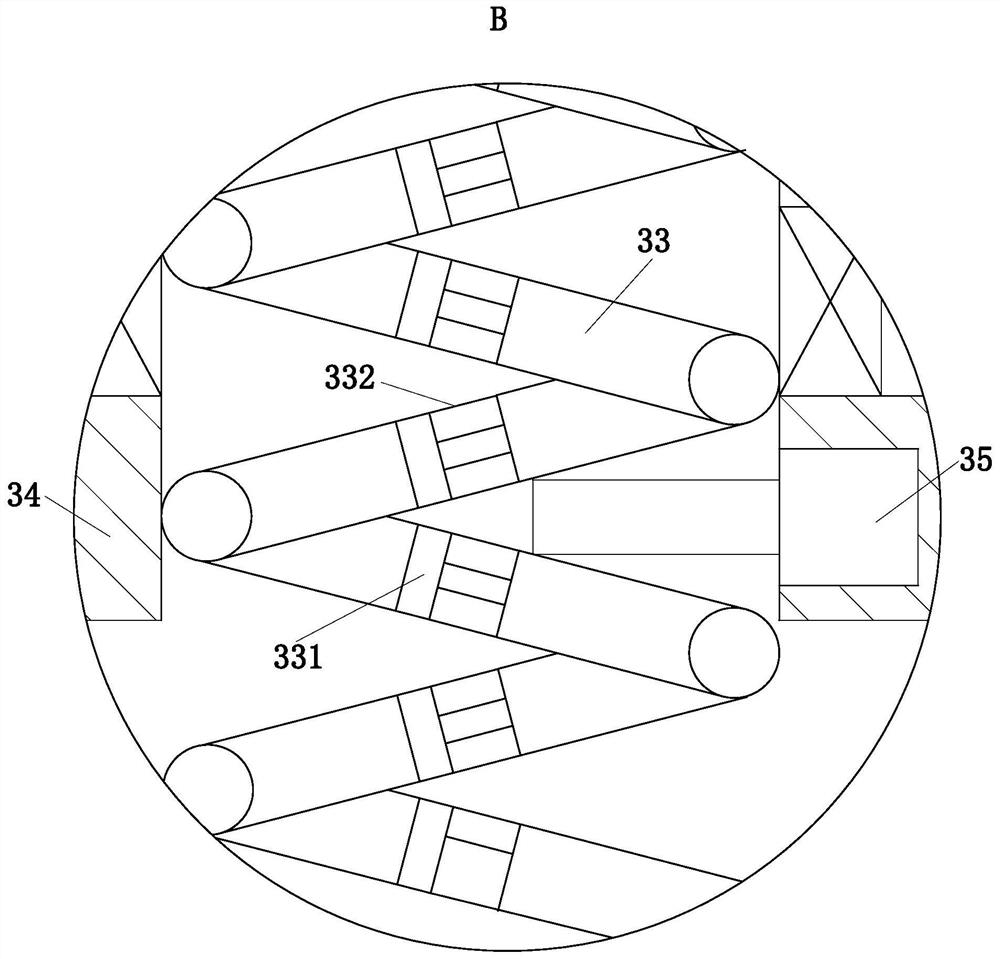

specific Embodiment approach

[0028] As a specific embodiment of the present invention, one slider 7 is provided below the first die 3, and the one pulley 7 is located between the shears 5 and the rotating shaft 2, and the rotating shaft 2 is provided with a second pulley 71. The second pulley 71 is wrapped around the rigid rope 72, and the other end of the rigid rope 72 passes through the back-mourway plate 73 from the one pulley 7; the rotating shaft 2 is opened, and the hitting plate 73 slides in the pass groove; When the first spring 33 is compressed, the striking plate 73 moves upward, and the striking plate 73 moves down the potatoes on the secondary turntable 4 when the first spring 33 is reset; the present invention is compressed by the first spring 33 to the striking plate 73 Move, when the first spring 33 is reset, the impact board 73 can impact the potatoes on the secondary turntable 4, which is conducive to the thorough shock of potatoes, and further increase the rate of potatoes into mashed potato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com