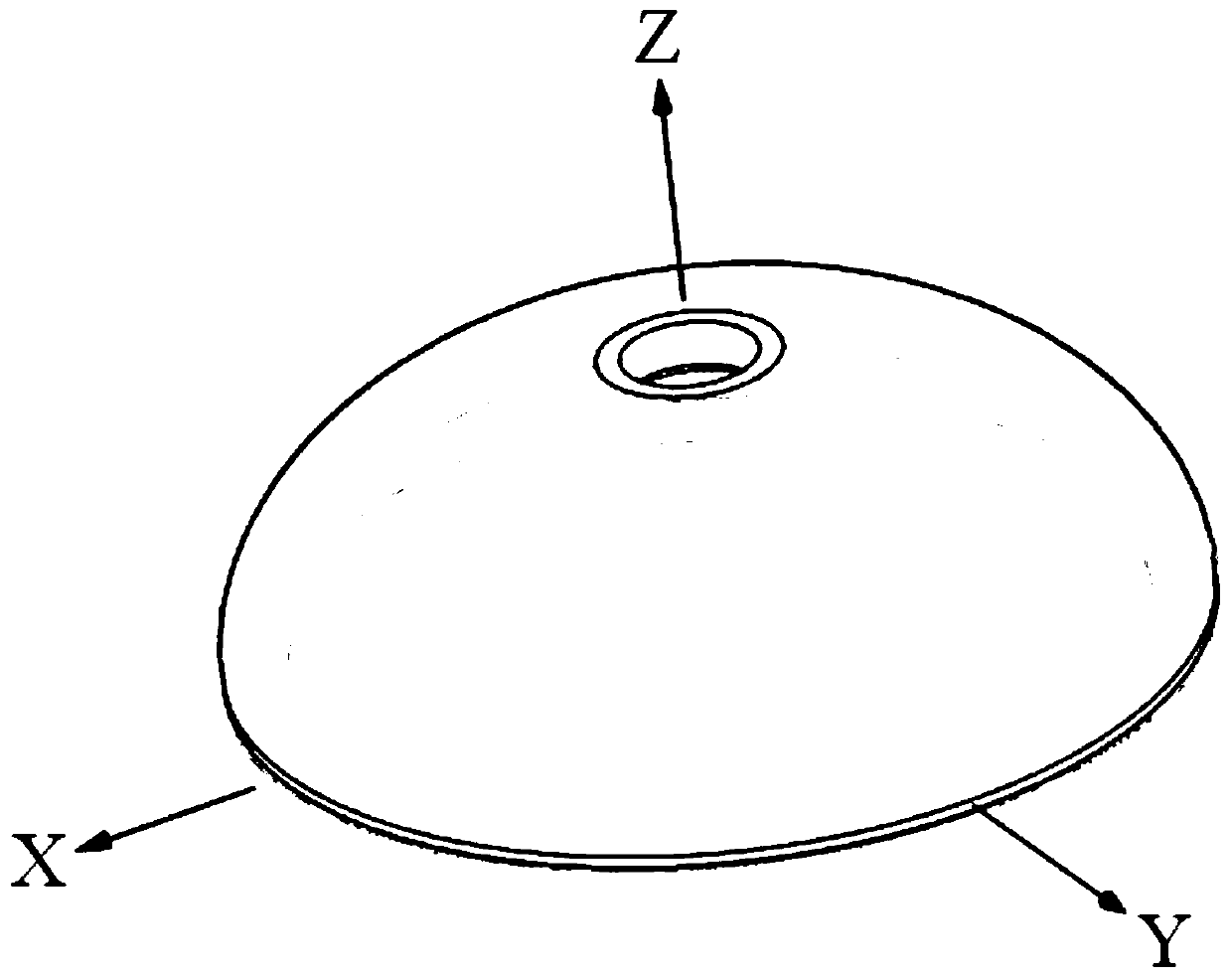

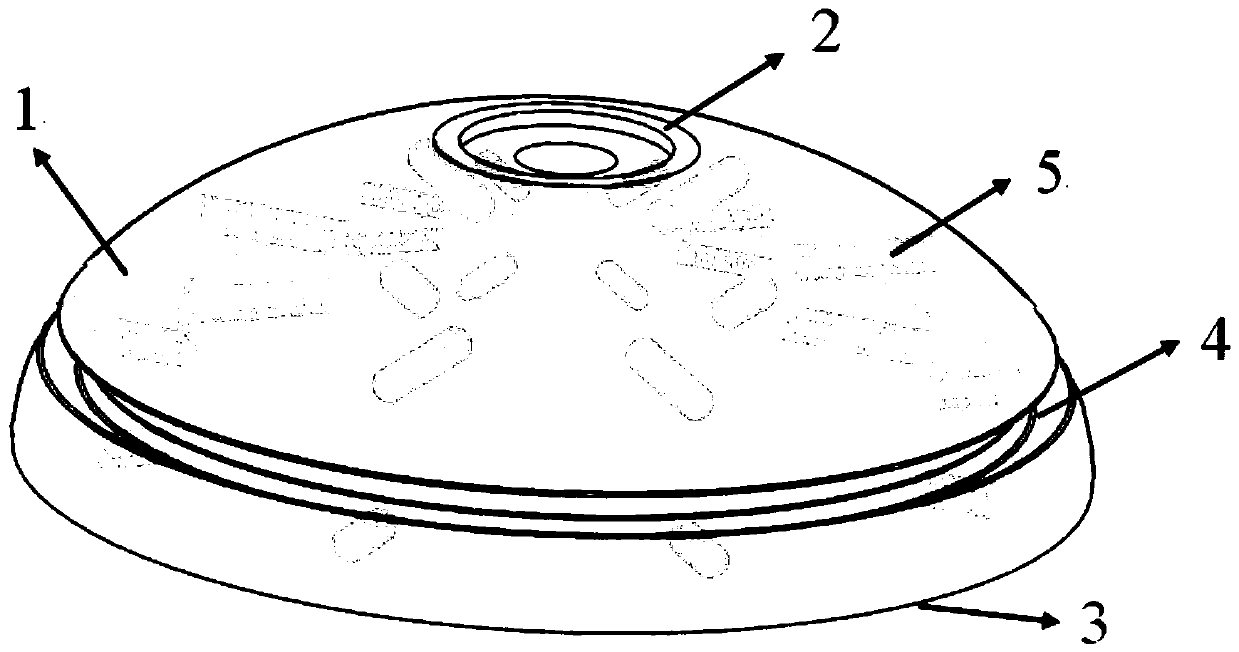

Tooling and method for controlling temperature field of spinning deformation temperature field of aluminum-lithium alloy storage tank hemispherical shell

An aluminum-lithium alloy, spinning deformation technology, applied in the direction of manufacturing tools, metal processing equipment, forming tools, etc., to achieve the effect of improving the forming quality and forming accuracy, and ensuring the uniformity of the temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

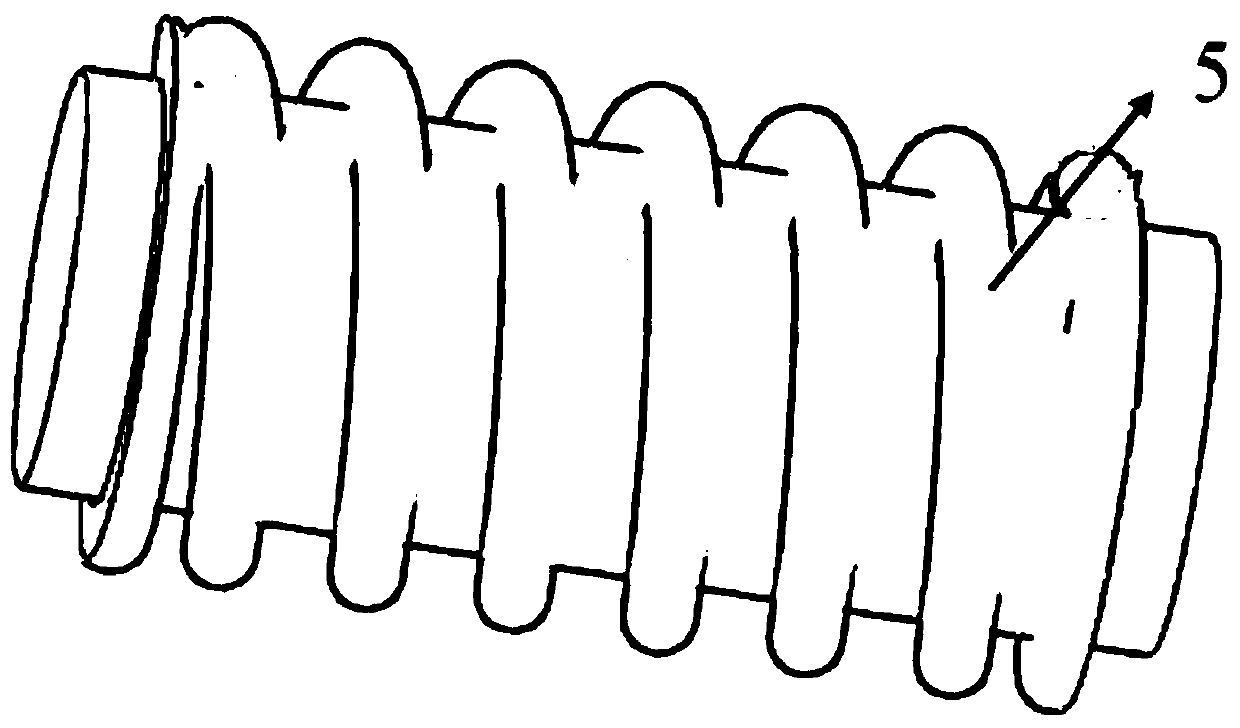

[0119] In this embodiment, the raw material of the hemispherical shell of the large-size high-performance 2195 aluminum-lithium alloy storage tank is Al-Cu-Li series aluminum-lithium alloy, and the mass content of its Cu element is 4.1% (mass percentage), and the mass content of Li element is 0.9% (mass percentage), the inner diameter of the hemispherical shell is Φ1380mm, and the depth of the hemispherical shell is 451.25mm. High performance refers to the tensile strength, yield strength and elongation of the hemispherical shell after spinning deformation and subsequent heat treatment. The rate is not lower than 570MPa, 530MPa, and 7.5%. The following is a specific process of controlling the temperature field of the spinning deformation temperature field of a large-scale high-performance 2195 aluminum-lithium alloy storage tank hemispherical shell:

[0120] A large-size high-performance 2195 aluminum-lithium alloy storage tank hemispherical shell spinning deformation temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com