Joint bearing inner sleeve outer spherical surface O-shaped oil groove machining device and machining method

A joint bearing and processing device technology, which is applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of shortened tool life, low processing efficiency of boring machines, and reduced tool clamping strength, etc., to achieve convenient clamping , Solve the production bottleneck problem, the effect of fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

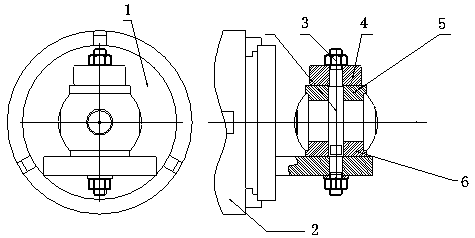

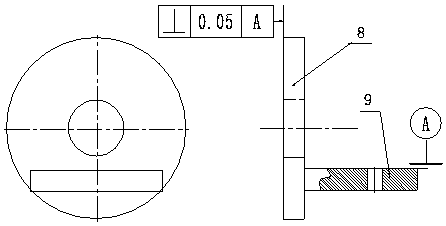

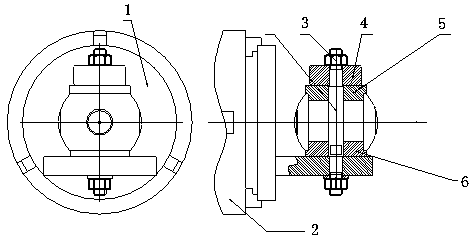

[0012] combined with figure 1 And attached figure 2 , an O-shaped oil groove processing device and processing method for the inner sleeve and outer spherical surface of the joint bearing of the present invention, including a fixture body (1), a three-jaw chuck (2), a positioning compression screw (3), and a compression nut ( 4), balance fast (5), gland (6) and self-aligning pad (7), wherein, the main body of the fixture is composed of a clamping disc (8) and a clamping base plate (9), and the two The ends are vertically connected, the connection mode of the positioning compression screw and the clamping base plate is a transition fit, and the connection mode of the self-aligning pad and the compression screw is a transition fit.

[0013] This device uses the clamping disc and the clamping base plate to be welded perpendicularly to each other, and then finely processes the working surface of the clamping base plate to meet the clamping of the mold by the three-jaw self-center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com