Automatic underpants sizing and stacking machine

A stacking machine and underwear technology, applied in the direction of setting/stretching endless fabrics, conveyors, mechanical conveyors, etc., can solve the problems of low operating efficiency, uneven stacking, and high labor intensity, so as to reduce labor intensity The effect of large, low efficiency improvement and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

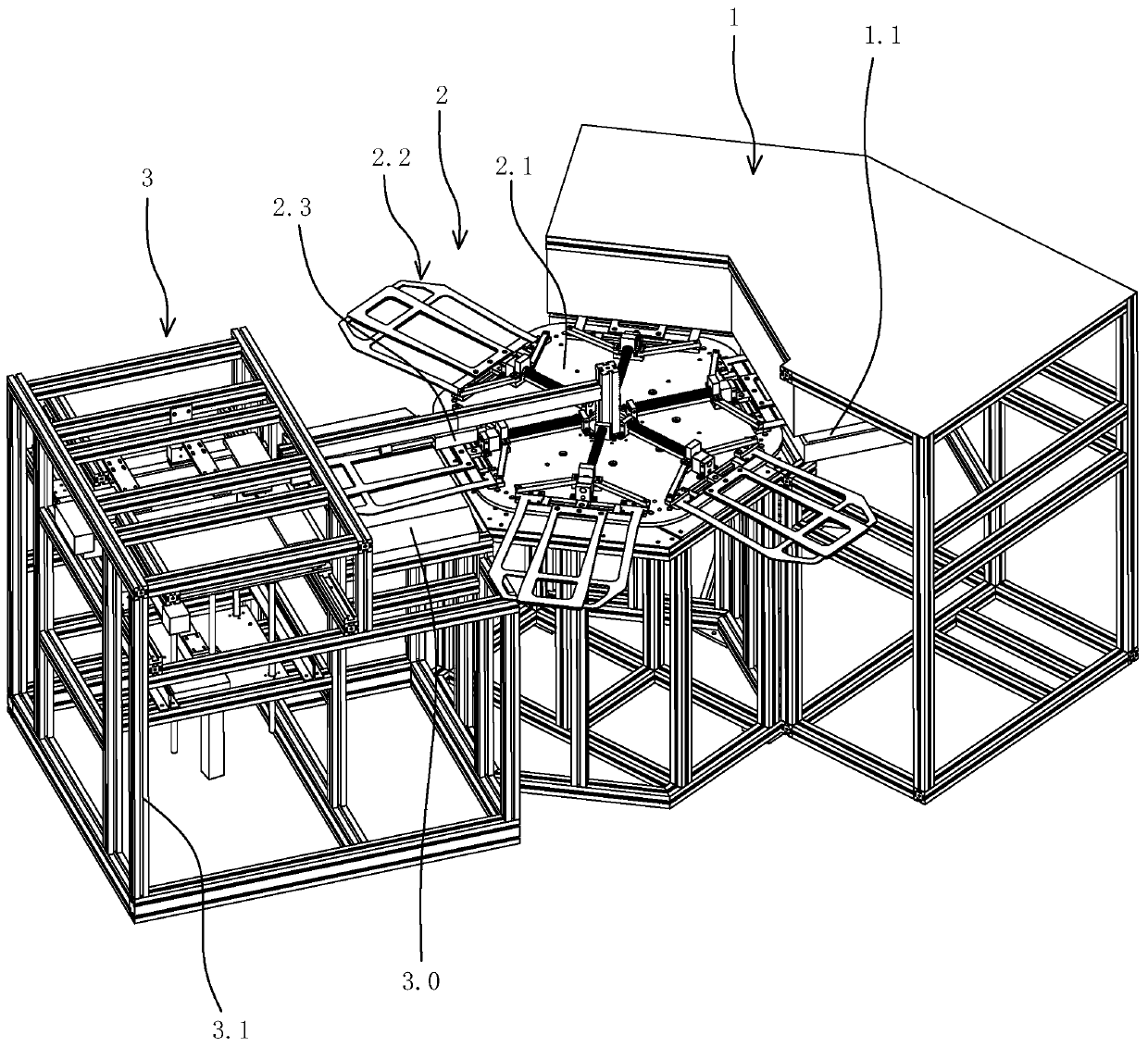

[0043] Specific embodiment one: as figure 1 As shown, an automatic underwear shaping and stacking machine includes an oven 1, a rotating trousers mechanism 2 and a trousers picking and stacking mechanism 3. In this embodiment, the oven and the pants taking and stacking mechanism are located on opposite sides of the rotating trousers mechanism.

[0044] The side of the oven is provided with a trouser board opening 1.1 which communicates with the inner cavity of the oven.

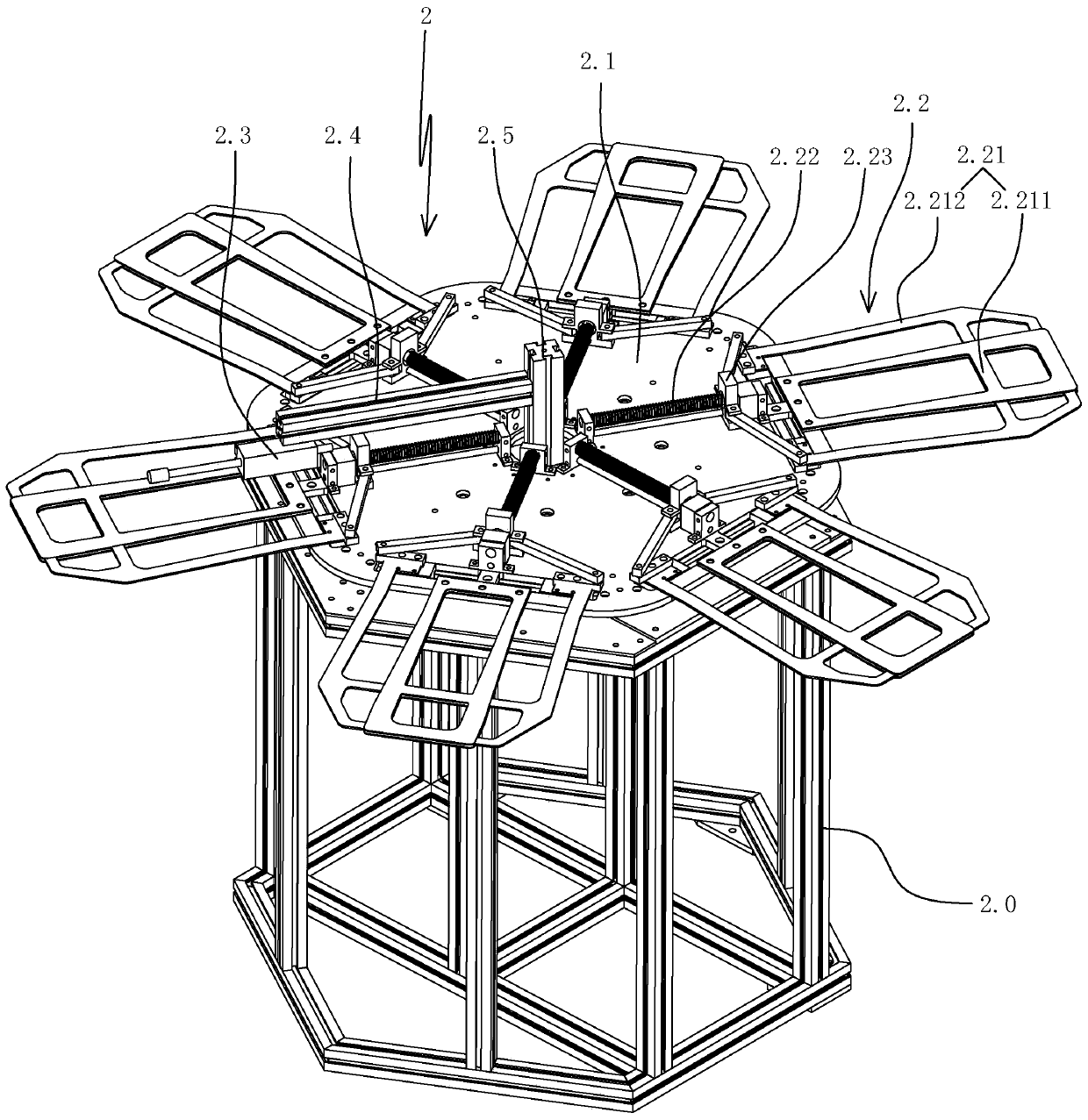

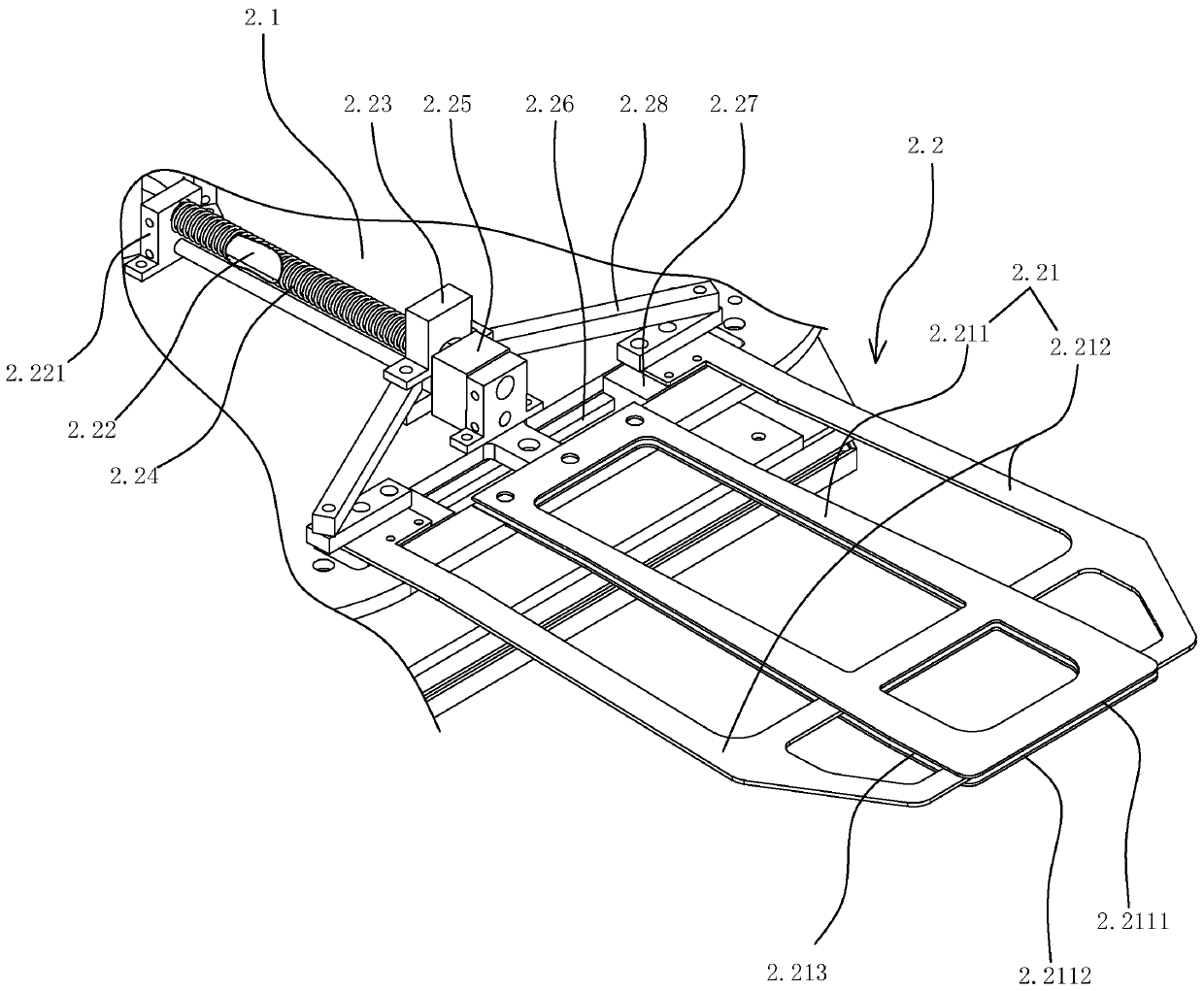

[0045] like figure 1 , figure 2 As shown, the rotating trousers mechanism includes an underframe 2.0, a rotating platform 2.1 arranged on the underframe through the rotation of the rotating shaft, a rotary actuator arranged on the underframe for driving the rotating platform, and at least three rotating shafts distributed in the circumferential direction. Chapsboard assembly on platform 2.2. Rotary actuators are rotary drive motors. The rotating platform is arranged horizontally, and the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com