Preservative for concrete admixture and preparation method thereof

A concrete admixture and preservative technology, applied in the field of preservatives, can solve the problems of lack of inhibition of mold growth and reproduction, influence of concrete performance, and high cost of protective layer, and achieves good anti-corrosion and mildew-proof effect, more concrete slurry, and compatibility. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

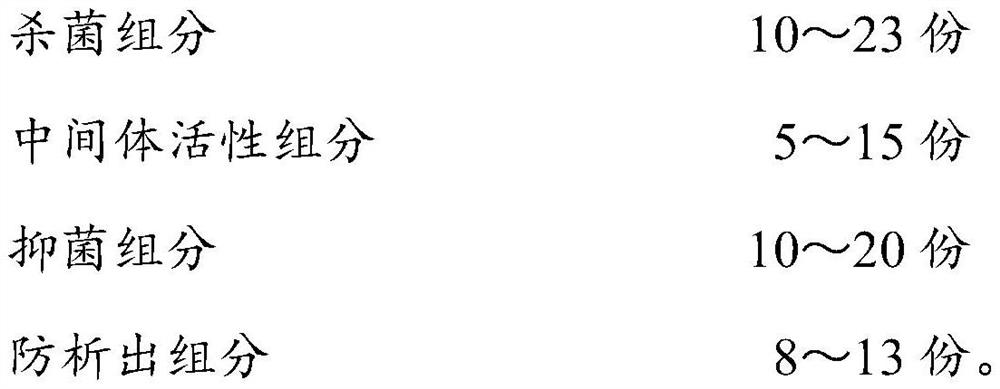

Method used

Image

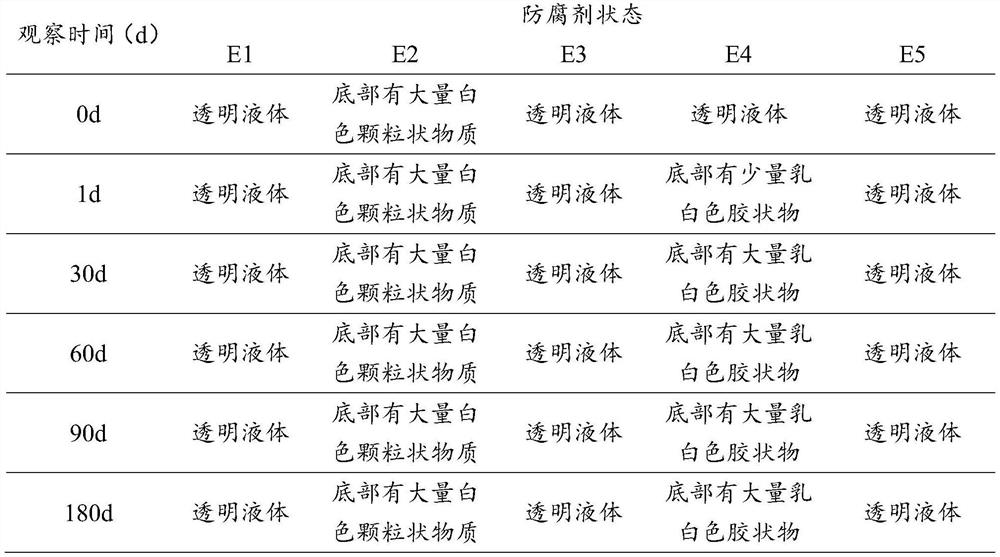

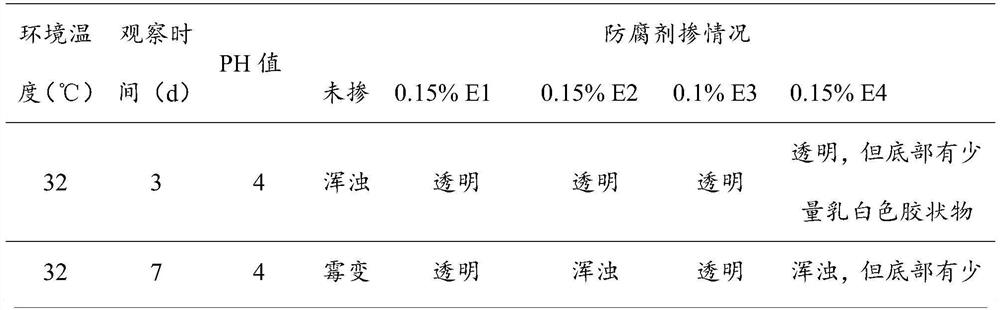

Examples

Embodiment 1

[0024] In parts by weight, 6 parts of acetic acid and 42 parts of water are made into solution A, 9 parts of tristyrylphenol polyoxyethylene ether components and 32 parts of water are made into solution B, and 15 parts of N-cyclopropyl- N'-(1,1-dimethylethyl)-6-(methylthio)-1,3,5-triazine-2,4-diamine and 108 parts of water were added to the reactor, and the temperature was adjusted. Stir to dissolve, and when the temperature rises to 85°C, add 13 parts of 2-n-octyl-4-isothiazolin-3-one into the reaction kettle; After the dropwise addition, start to add solution B dropwise at a constant speed for 2 hours. After the dropwise addition, keep the temperature constant for 2 hours to obtain a preservative E1 for concrete admixture.

Embodiment 2

[0026] In parts by weight, 9 parts of tristyrylphenol polyoxyethylene ether components and 74 parts of water are formulated into solution A, and 15 parts of N-cyclopropyl-N'-(1,1-dimethylethyl )-6-(methylthio)-1,3,5-triazine-2,4-diamine and 108 parts of water were added to the reaction kettle, the temperature was adjusted, stirred and dissolved, and when the temperature rose to 85°C, 13 parts Mix 2-n-octyl-4-isothiazolin-3-one into the reaction kettle; stir for one hour, start to add solution A dropwise at a constant speed, and the dropping time is 2 hours. After the dropping, keep the temperature for 2 hours to obtain a Preservative E2 for concrete admixture.

Embodiment 3

[0028] 8 parts of phosphoric acid and 45 parts of water are made into solution A, 13 parts of fatty alcohol polyoxyethylene ether and 38 parts of water are made into solution B, and 12 parts of 2,2-dibromo-3-cyano(nitrile) propionamide Add 105 parts of water into the reaction kettle, adjust the temperature, stir and dissolve, and when the temperature rises to 85°C, add 15 parts of 2-n-octyl-4-isothiazolin-3-one into the reaction kettle; then add it dropwise at a constant speed Solution A, the dropping time is 1.5h. After the solution A is added dropwise, start to add solution B dropwise at a constant speed. The dropping time is 2h. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com