A kind of gradient three-dimensional through hole ventilation plug and preparation method thereof

A technology for venting plugs and through-holes, applied in the field of gradient three-dimensional through-hole venting plugs and its preparation, which can solve problems such as easy air leakage, reduced air flow, and reduced service life of venting plugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

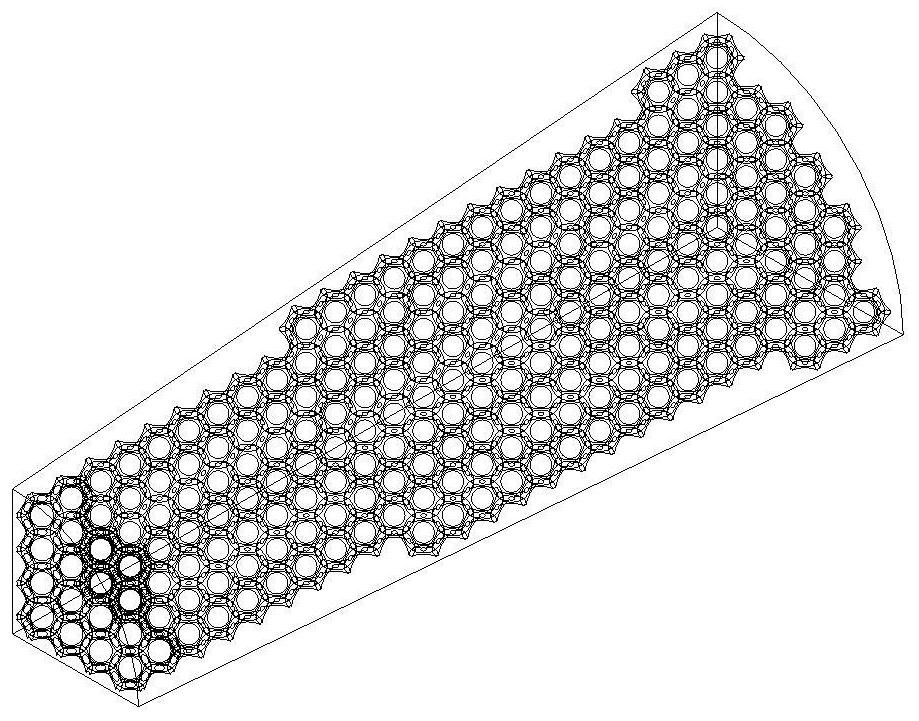

[0058] A gradual three-dimensional through-hole ventilation plug and a preparation method thereof. The preparation method described in this embodiment is:

[0059] Construct a three-dimensional hole skeleton geometric model, in which the parameters are as follows:

[0060] a=H / n 1 (1)

[0061] d=k×a (2)

[0062] no 2 = 2r 上 / a (3)

[0063] no 3 = 2r 中 / a (4)

[0064] no 4 = 2r 下 / a (5)

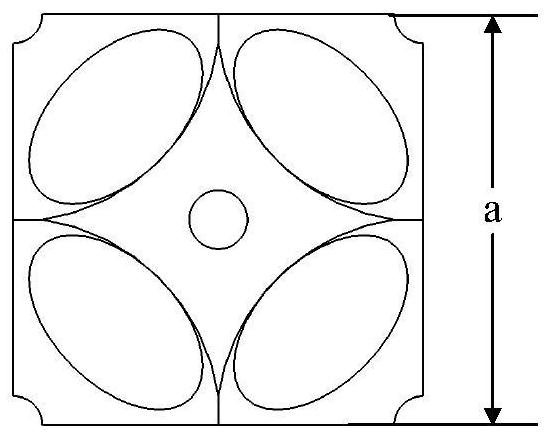

[0065] In the formulas (1) to (5): a represents the side length of a single cell in the geometric model of the three-dimensional hole skeleton, mm;

[0066] H represents the height of the vent plug, mm;

[0067] no 1 Indicates the number of layers of a single cell in the three-dimensional hole skeleton geometric model;

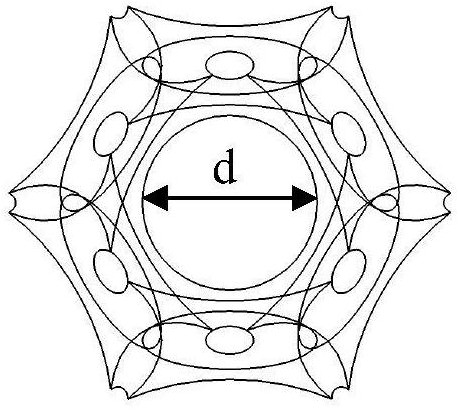

[0068] d represents the diameter of a single cell in the three-dimensional hole skeleton geometric model, mm;

[0069] k represents the scale factor of a single cell in the three-dimensional hole skeleton geometric model;

[0070] no 2 Indicates the number o...

Embodiment 2

[0085] A gradual three-dimensional through-hole ventilation plug and a preparation method thereof. The preparation method described in this embodiment is:

[0086] Construct a three-dimensional hole skeleton geometric model, in which the parameters are as follows:

[0087] a=H / n 1 (1)

[0088] d=k×a (2)

[0089] no 2 = 2r 上 / a (3)

[0090] no 3 = 2r 中 / a (4)

[0091] no 4 = 2r 下 / a (5)

[0092] In the formulas (1) to (5): a represents the side length of a single cell in the geometric model of the three-dimensional hole skeleton, mm;

[0093] H represents the height of the vent plug, mm;

[0094] no 1 Indicates the number of layers of a single cell in the three-dimensional hole skeleton geometric model;

[0095] d represents the diameter of a single cell in the three-dimensional hole skeleton geometric model, mm;

[0096] k represents the scale factor of a single cell in the three-dimensional hole skeleton geometric model;

[0097] no 2 Indicates the number o...

Embodiment 3

[0111]A gradual three-dimensional through-hole ventilation plug and a preparation method thereof. The preparation method described in this embodiment is:

[0112] Construct a three-dimensional hole skeleton geometric model, in which the parameters are as follows:

[0113] a=H / n 1 (1)

[0114] d=k×a (2)

[0115] no 2 = 2r 上 / a (3)

[0116] no 3 = 2r 中 / a (4)

[0117] no 4 = 2r 下 / a (5)

[0118] In the formulas (1) to (5): a represents the side length of a single cell in the geometric model of the three-dimensional hole skeleton, mm;

[0119] H represents the height of the vent plug, mm;

[0120] no 1 Indicates the number of layers of a single cell in the three-dimensional hole skeleton geometric model;

[0121] d represents the diameter of a single cell in the three-dimensional hole skeleton geometric model, mm;

[0122] k represents the scale factor of a single cell in the three-dimensional hole skeleton geometric model;

[0123] no 2 Indicates the number of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com