Withered leaf fertilizer making device

A dead leaf and leaf technology, applied in the field of dead leaf fertilizer making device, can solve problems such as poor ventilation, achieve the effect of solving the ventilation problem and preventing the fermentation temperature from being too high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

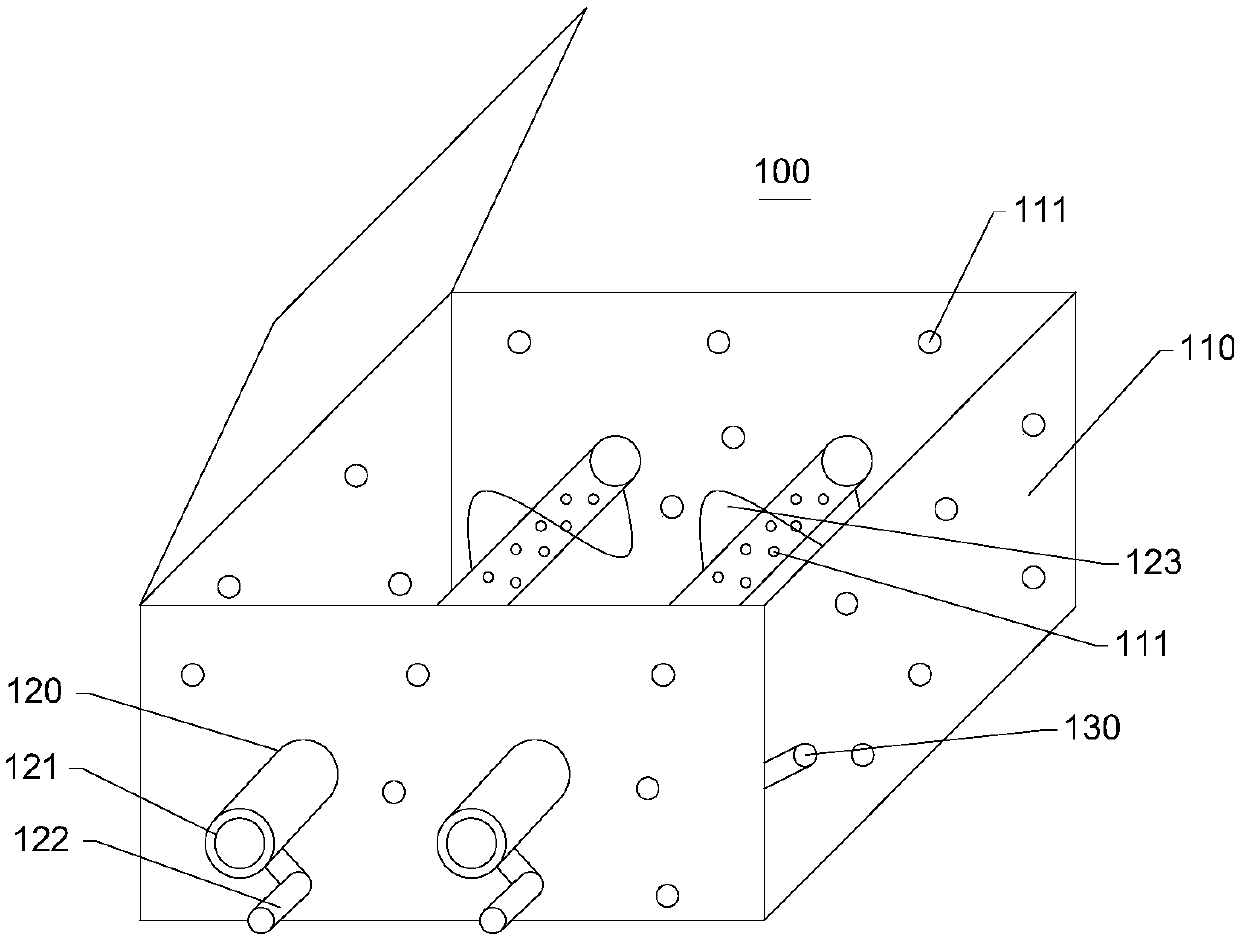

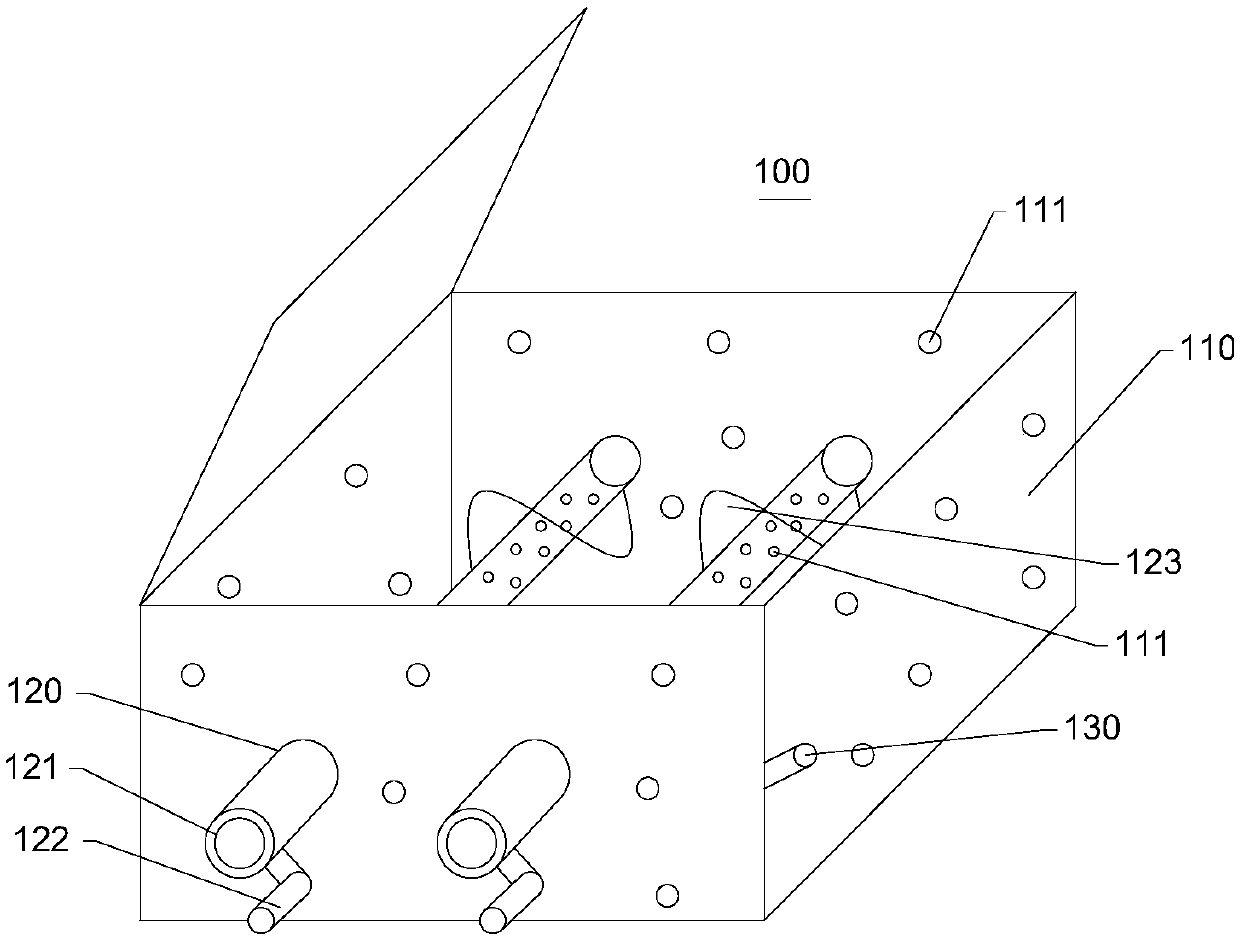

[0024] Please refer to figure 1 , the present embodiment provides a dead leaf fertilizer making device 100, which includes a fermentation tank 110, a stirring assembly 120 and a temperature tester 130, a part of the temperature tester 130 is located in the fermentation tank 110, and the other part of the temperature tester 130 is located in the fermentation tank 110. Outside the tank 110 , the stirring component 120 is disposed in the fermentation tank 110 .

[0025] The stirring assembly 120 is arranged in the fermentation tank 110, and the stirring assembly 120 is connected to the opposite side walls of the fermentation tank 110. The stirring assembly 120 includes a stirring shaft 121, a mixing blade 123, a hand-held roller 122 and a ventilation hole 111. The device is provided with two Stirring assembly 120; the stirring shaft 121 is elongated and cylindrical, the section of the stirring shaft 121 is ring-shaped, the inside of the stirring shaft 121 is hollow, and the two e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com