Novel compact drill bit

A composite piece drill bit and composite piece technology, which are applied to drill bits, drilling equipment, earthwork drilling and other directions, can solve the problems of shortening the service life of the drill bit, poor impact resistance, poor wear resistance, etc., and improve the service life and impact resistance. The effect of strong ability and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

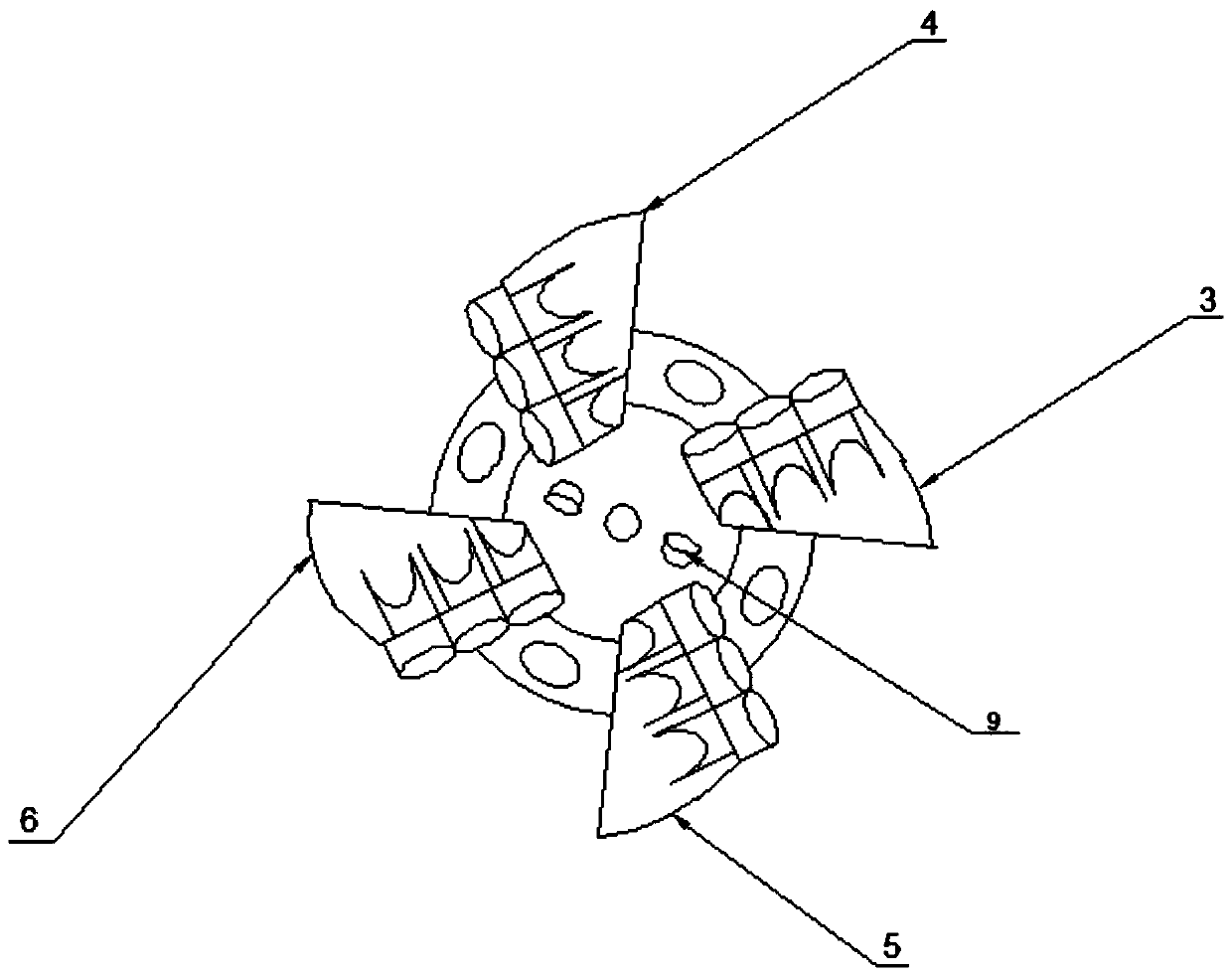

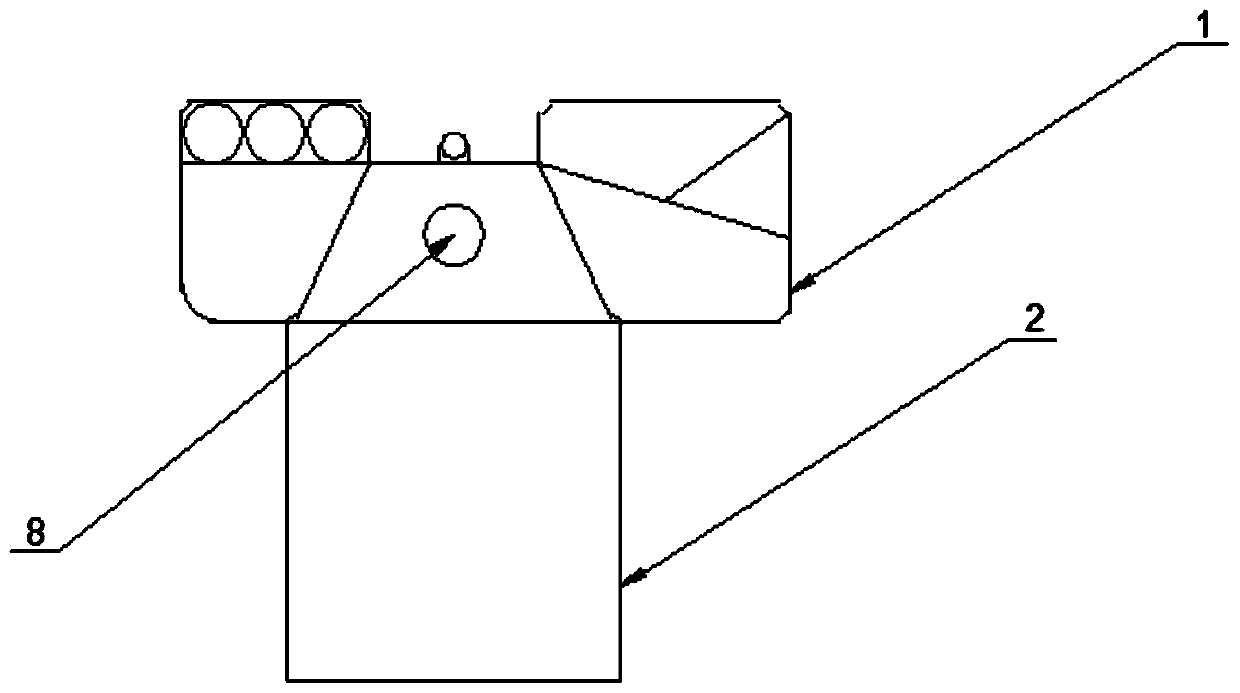

[0017] combined with Figure 1-3 , the present invention is described in detail.

[0018] The present invention provides a new type of composite drill bit during specific implementation, including a drill head 1 and a shank 2, the shank 2 is arranged above the drill head 1, and the shank 2 includes a first drill head 3, a second shank Two drill parts 4, the third drill part 5 and the fourth drill part 6, the first drill part 3, the second drill part 4, the third drill part 5 and the fourth drill part 6 are all provided with a composite sheet 7, The composite sheet 7 is arranged in a linear structure, and the outer peripheral surfaces of the first drill part 3 , the second drill part 4 , the third drill part 5 and the fourth drill part 6 are arranged in a smooth arc-shaped structure.

[0019] The composite sheet 7 is a diamond composite sheet, and the first ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap