Closing system of rotary support of pneumatic motor

A technology of slewing bearings and air motors, which is applied to the sealing of engines, rigid supports of bearing components, bearing components, etc., and can solve problems such as damage to slewing bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in connection with the drawings and embodiments.

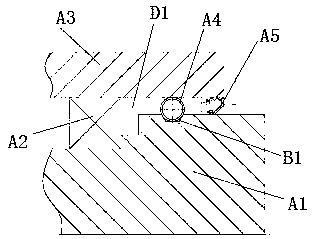

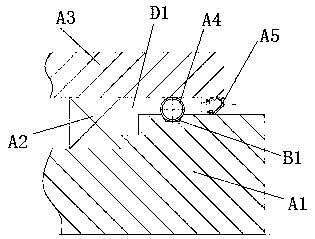

[0015] Such as figure 1 As shown, the closed system of the slewing bearing of the air motor includes a roller body A1, a slewing bearing A2, a slewing bearing platform A3 and a ring-shaped sieve plate equipment A4. The slewing bearing platform A3 is equipped with an anti-rust hole D1 for placing the slewing bearing A2 , the slewing bearing A2 is hooped on the roller body A1 and filled into the anti-rust hole D1 through one end of the anti-rust hole D1.

[0016] A sealing portion A5 is provided between the roll body A1 and one end of the anti-rust hole D1 to seal the seam between the roll body A1 and one end of the anti-rust hole D1.

[0017] The sieve plate equipment A4 is hooped at the position between the slewing support A2 and the sealing part A5 on the roller body A1, and the outer surface of the sieve plate equipment A4 is in contact with the inner surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com