Turbine condenser vacuum-pumping system with coolers and control method

A technology of vacuum pumping system and cooling device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

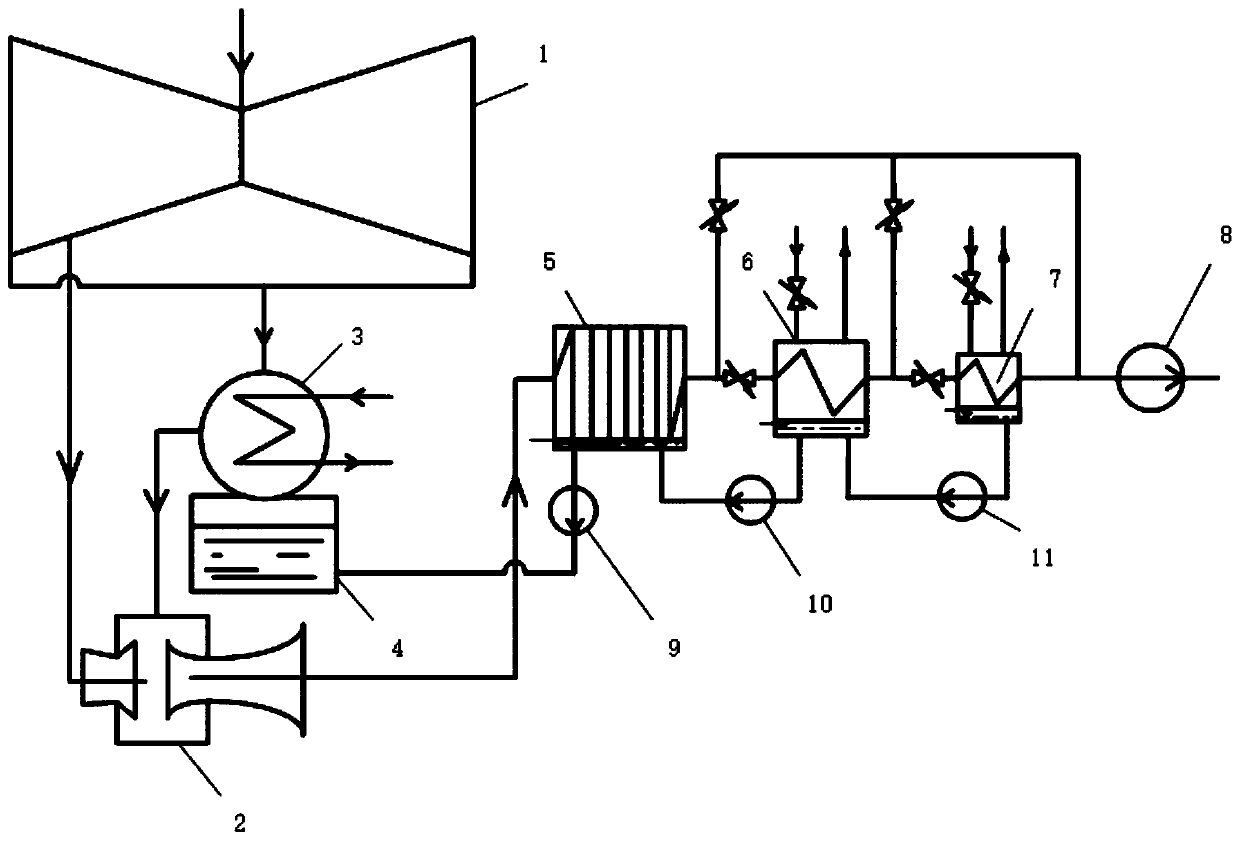

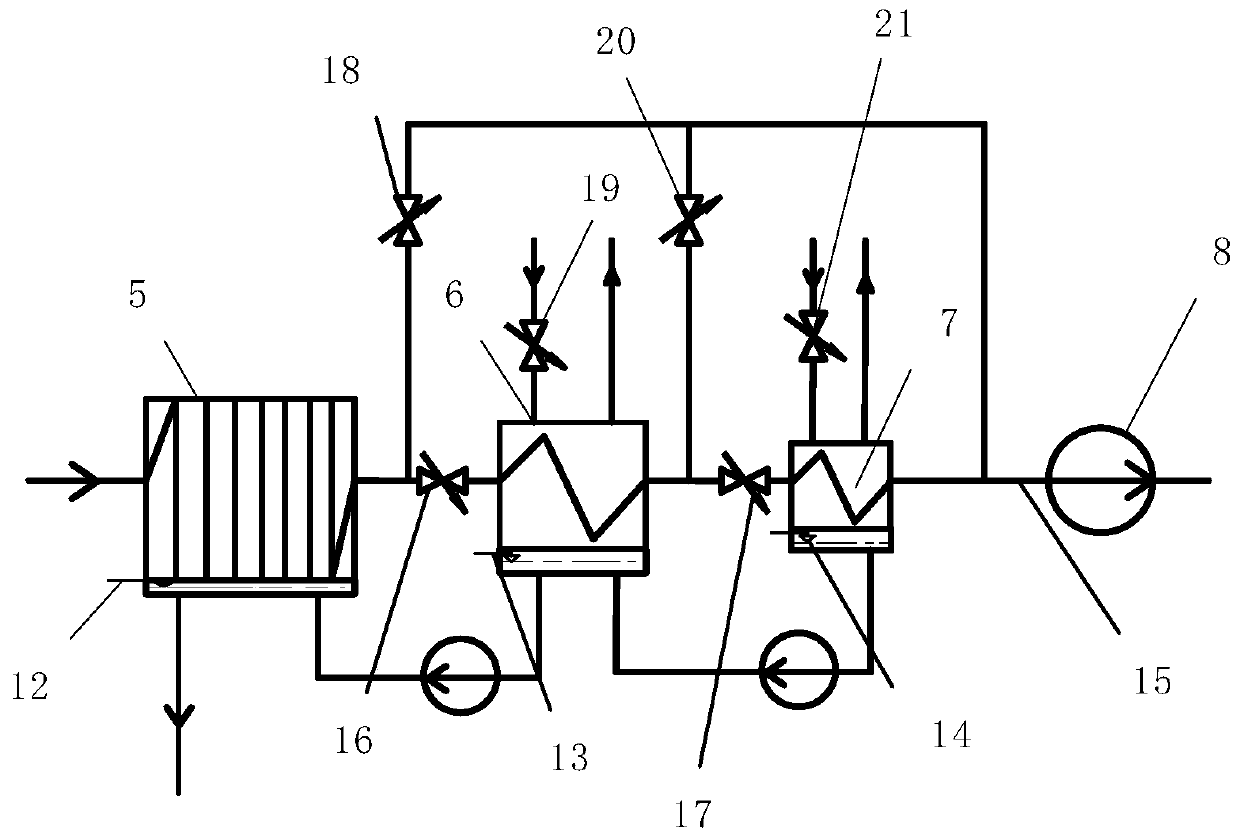

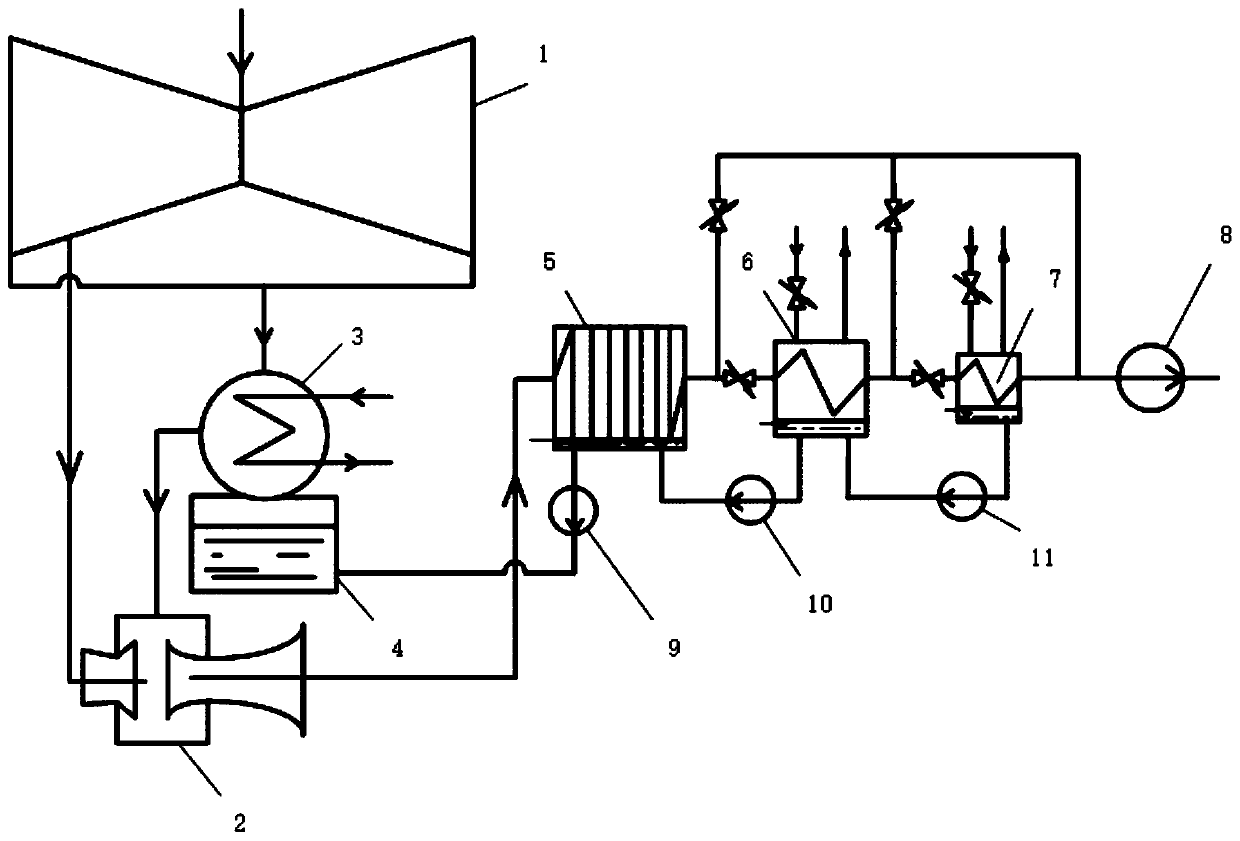

[0031] A vacuum pumping system for a steam turbine condenser with a cooling device of the present invention includes a vacuum pump 8 and three sequentially connected cooling devices, specifically an air cooler 5, a cooling water cooler 6 and a chilled water cooler 7; and a steam turbine 1. Steam jet extractor 2, condenser 3, hot well 4, and pipelines connecting each component; the second-end high-temperature and high-pressure exhaust outlet of the steam turbine 1 passes through the pipeline and the jet port of steam jet extractor 2 Connect, the exhaust steam outlet of steam turbine 1 is connected with the inlet of condenser 3 through pipeline; The outlet of described condenser 3 is connected with the inlet of steam ejector 2 through pipeline, and it is also connected hot well 4; The working s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com