Gas tightness detecting device, waterproof structure of lamp body, and gas tightness detection and sealing method

A technology for air tightness detection and waterproof structure, which is used in the liquid/vacuum degree of liquid tightness measurement, marine signal device, engine sealing, etc. It can solve the problem of air tightness loss, which is difficult to control and detect, and product quality. , safety hazards and other issues, to achieve the effect of reducing testing costs, reducing air tightness, and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] With the popularization and application of electronic components and equipment, more and more attention has been paid to the research on the airtight function direction. The airtight characteristic has become a necessary and primary quality index when electronic components are used in water environment, dust environment or other special environments.

[0036] Most of the existing technologies require that the product be placed in a water environment to be pressurized for air tightness testing, and many products need to add inspection tools to the interface, and the interface wear caused by the addition of inspection tools is difficult to avoid, and the loss of air tightness caused by interface wear It is also difficult to control and detect; for workpieces that have high precision requirements for air tightness or that need to be operated in special environments such as water environments, the workpiece needs to be sealed after the detection of the inspection tool, and th...

Embodiment 2

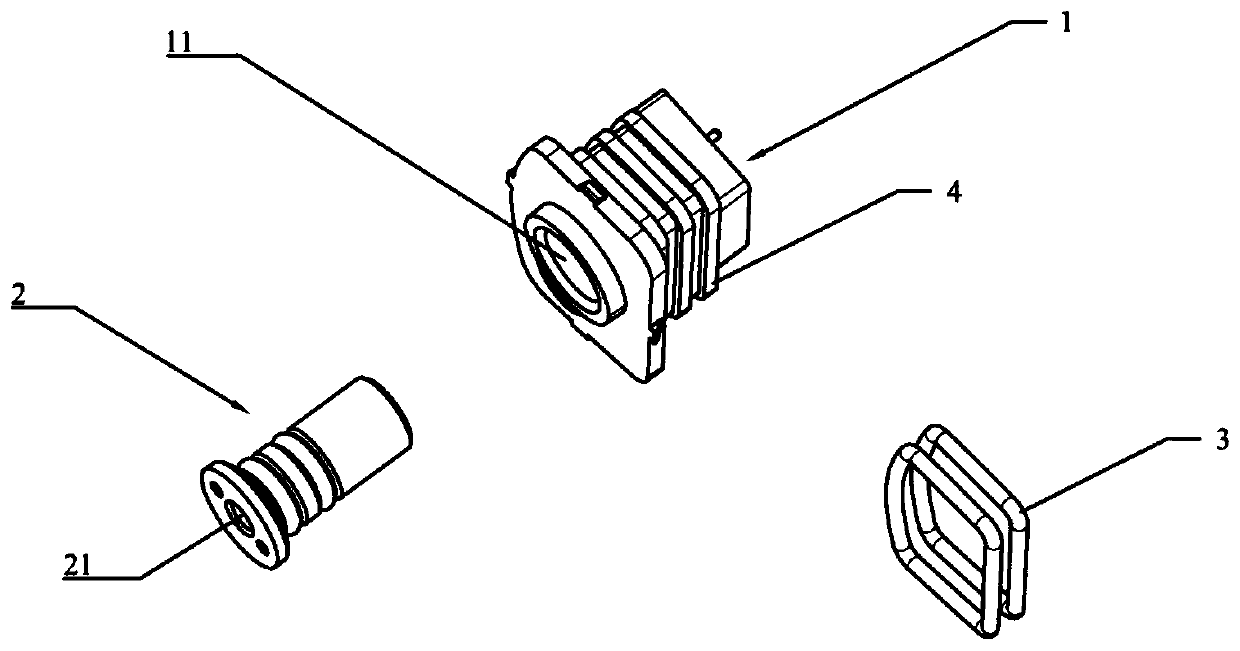

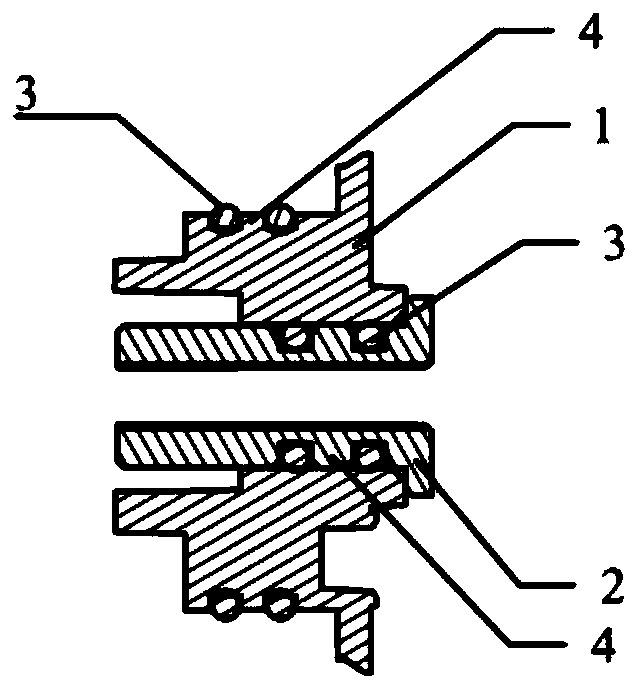

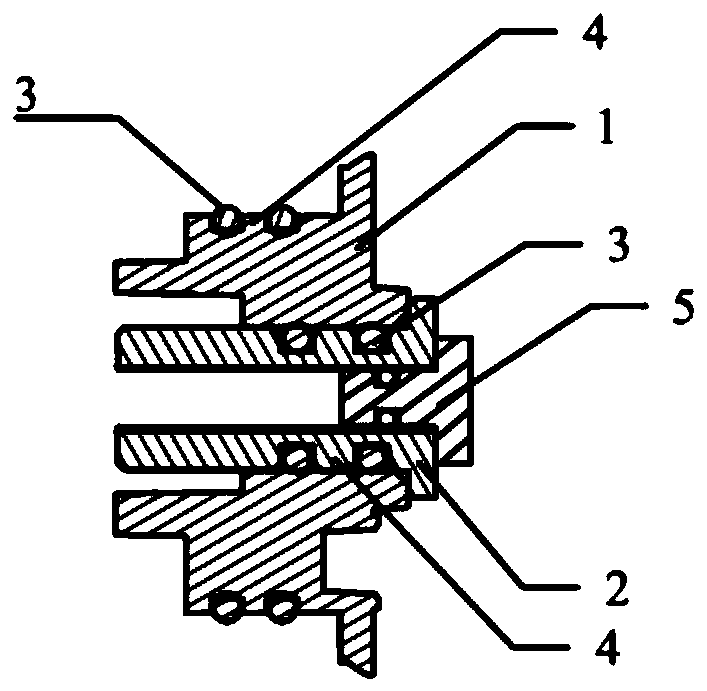

[0040] In order to further improve the convenience of operation, on the basis of Embodiment 1, this embodiment provides an air tightness detection device with an additional blocking member (5), such as image 3 As shown, the blocking member (5) is sealingly arranged inside the second through hole (21), and the blocking member is a cylindrical core with several sealing rings (3) on the outside and tightly abuts against the second through hole through the sealing ring. On the inner side of the hole, the setting of the sealing member enables the air tightness detection device to be directly used to seal the open end of the workpiece to be tested. After the air tightness is tested, there is no need to replace the device or adapt a new blocking element, and it can be directly used in the The airtightness detection device completes the sealing operation of the workpiece to be tested on the basis of the airtightness detection device, thereby reducing the possibility of air leakage of ...

Embodiment 3

[0042] This embodiment provides a waterproof structure of the lamp body on the basis of Embodiment 1-2. Its sealing setting can not only withstand the preset water pressure, but also directly test the airtightness through the airtightness detection device. The specific structure Such as Figure 4-5 As shown, it has an airtightness detection device, and also includes a waterproof casing (6) and an LED lamp group (7), wherein the waterproof casing (6) is a semi-closed workpiece with only one end open, and the airtightness detection device is installed The open end forms a sealable waterproof accommodation space with the waterproof casing, and the LED lamp group (7) is arranged inside the waterproof casing, wherein the LED lamp group includes an LED bulb (71) and a circuit board electrically connected to the LED bulb ( 72). In order to speed up the heat dissipation and prevent the LED lamp group from overheating, the circuit board is made of heat-conducting material. The interfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com