A method for calculating a steam humidity load distribution non-uniformity coefficient of a corrugated plate dryer assembly in a steam-water separation dryer system

A technology of steam-water separation and uniform coefficient, which is applied in separation methods, chemical instruments and methods, calculations, etc., and can solve problems such as the decline of drying performance of corrugated plate dryers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

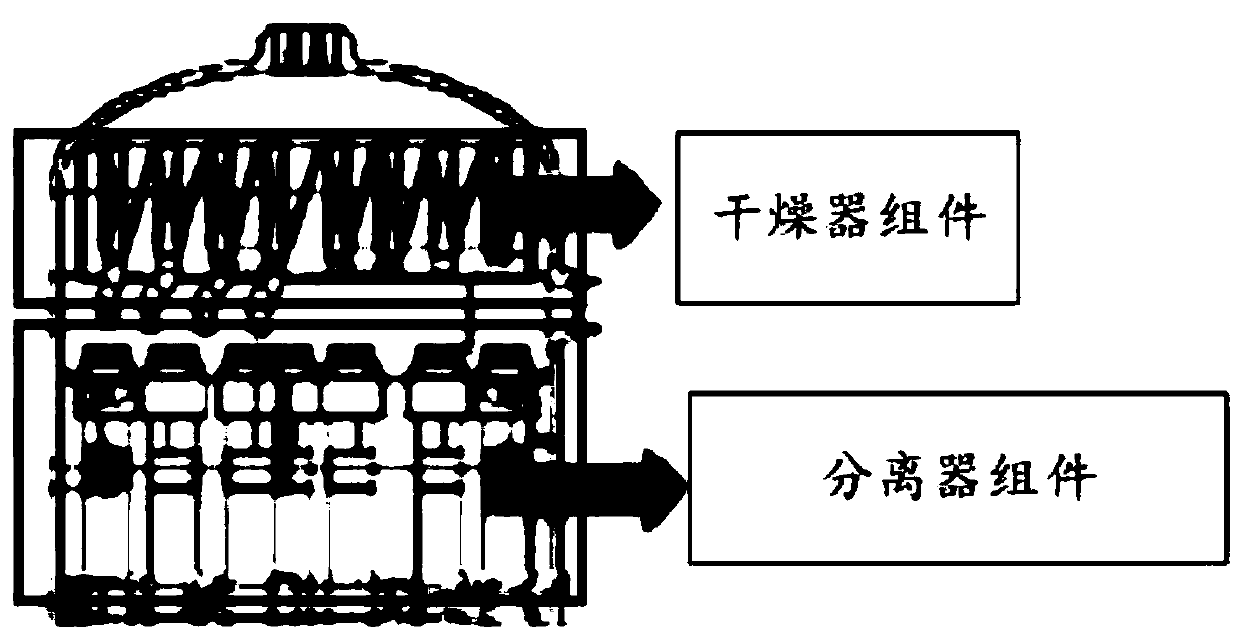

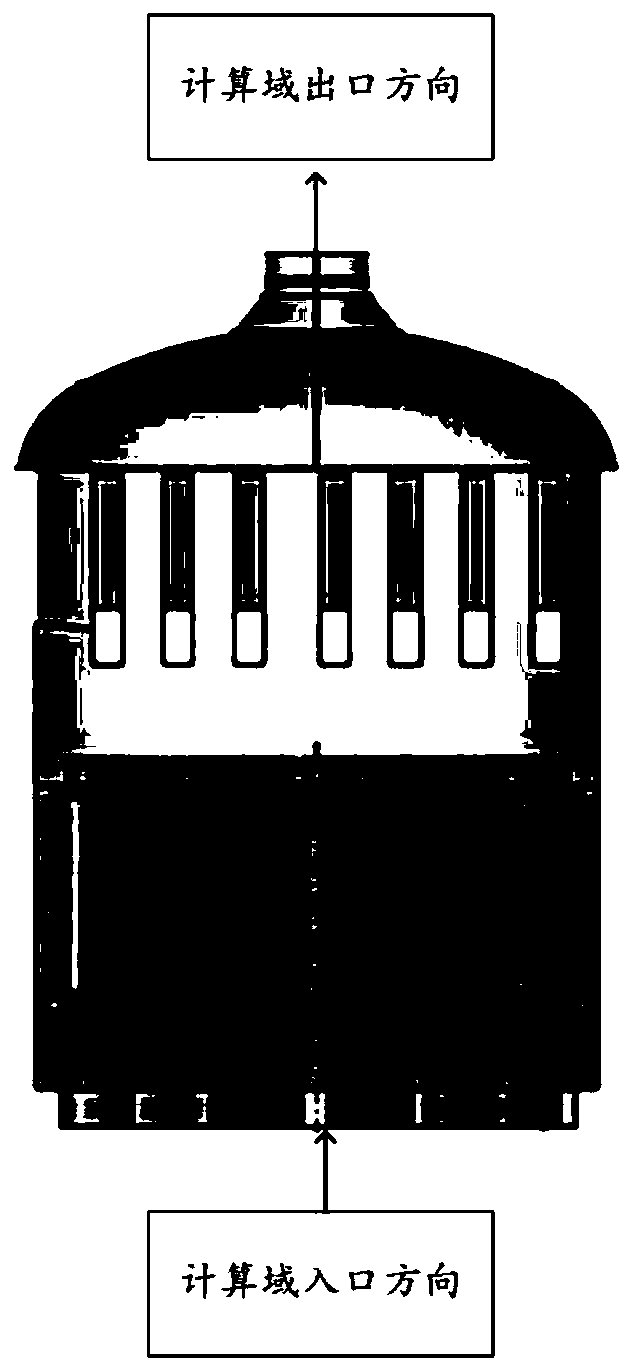

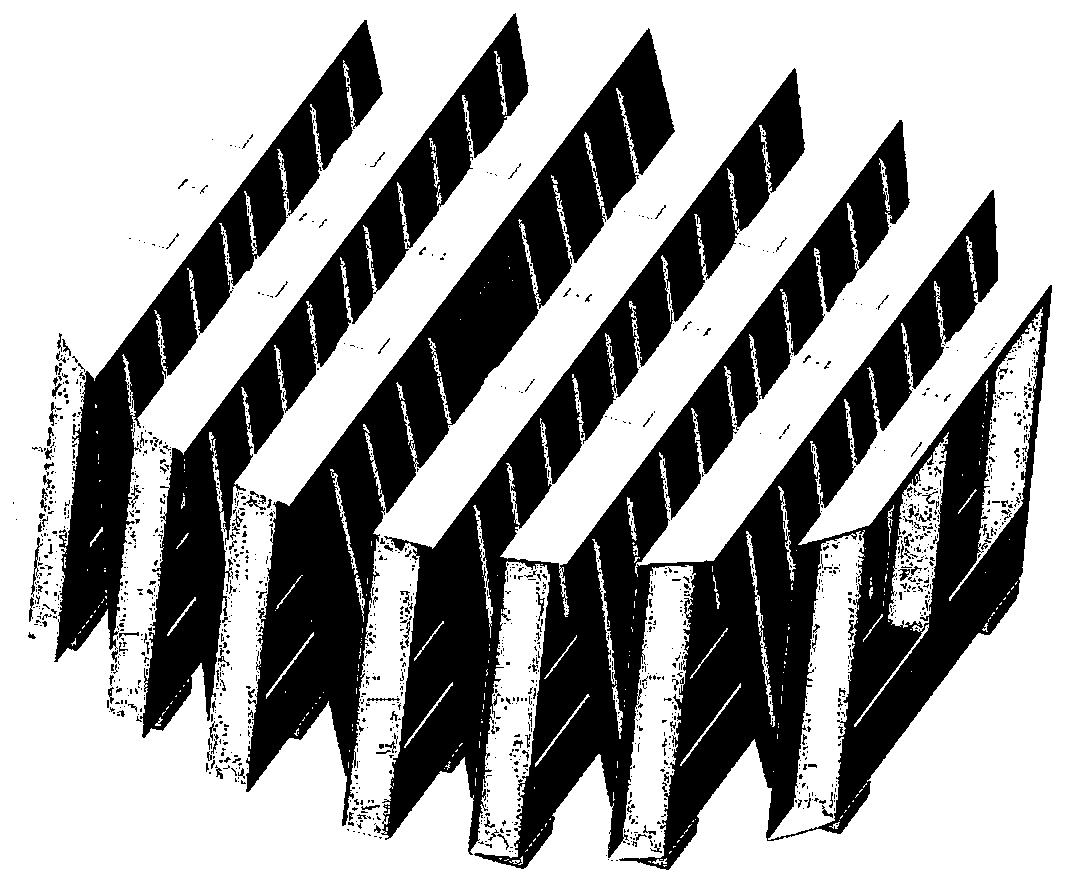

[0083] The following combination Figure 5 The flow chart shown in the advanced pressurized water reactor is an example of the calculation process of the continuous phase steam humidity load non-uniformity coefficient at the entrance of each corrugated plate drier unit in the drier assembly in the steam generator in the advanced pressurized water reactor. Further detailed description. The geometric structure of the vapor-water separation dryer system in the steam generator in the advanced pressurized water reactor is as follows: figure 1 shown.

[0084] The present invention is a method for calculating the uneven coefficient of steam humidity load distribution at the entrance of a corrugated plate dryer unit, comprising the following steps:

[0085] Step 1: Use the computational fluid dynamics software ANSYS-FLUENT to calculate the steady-state flow field of the continuous phase steam in the steam-water separation dryer system. The specific steps are as follows:

[0086] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com