Recyclable water washing and alkali reducing method for ternary material of lithium ion battery

A lithium-ion battery, ternary material technology, applied in electrical components, battery electrodes, secondary batteries, etc., can solve the problems of complex wastewater treatment process, high cost, waste of water resources, etc., and achieve simple process, water resources and wastewater. The effect of low processing cost and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

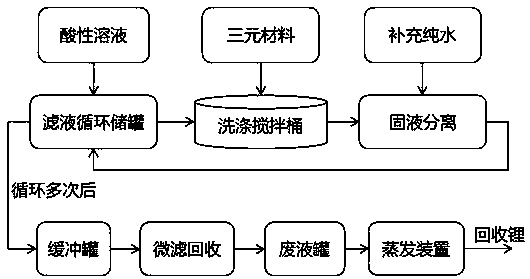

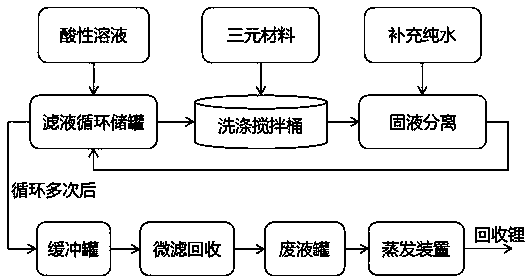

[0021] Such as figure 1 As shown, the present invention provides the following technical solutions: a recyclable water-washing and alkali-reducing method for ternary materials of lithium-ion batteries, using circulating filtrate to wash 811 ternary positive electrode materials, comprising the following steps:

[0022] 1) Add 0.1m3 deionized water into the mixing tank, add 100kg 811 ternary cathode material, stir for 30 minutes, put the slurry into the centrifuge, and after the preliminary solid-liquid separation, add 0.01m3 water to rinse the filter cake, and the filtrate enters the circulation storage tank , adding H2SO4 solution to adjust the pH value of the filtrate to 5.0;

[0023] 2) Use 0.1m of the filtrate from step 1) 3 , to wash the next batch of ternary cathode materials, other steps are the same as step 1);

[0024] 3) The cycle treatment steps are the same as step 2), and the positive electrode materials obtained by different cycles are tested to evaluate the was...

Embodiment 2

[0026] The difference from Example 1 is that the positive electrode material is NCA, and the circulating water washing steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com