A large-capacity high-temperature superconducting motor

A high-temperature superconducting, large-capacity technology, applied in the field of large-capacity offshore direct-drive wind turbines or marine propulsion motors, superconducting motors, and can solve problems such as increased compensation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

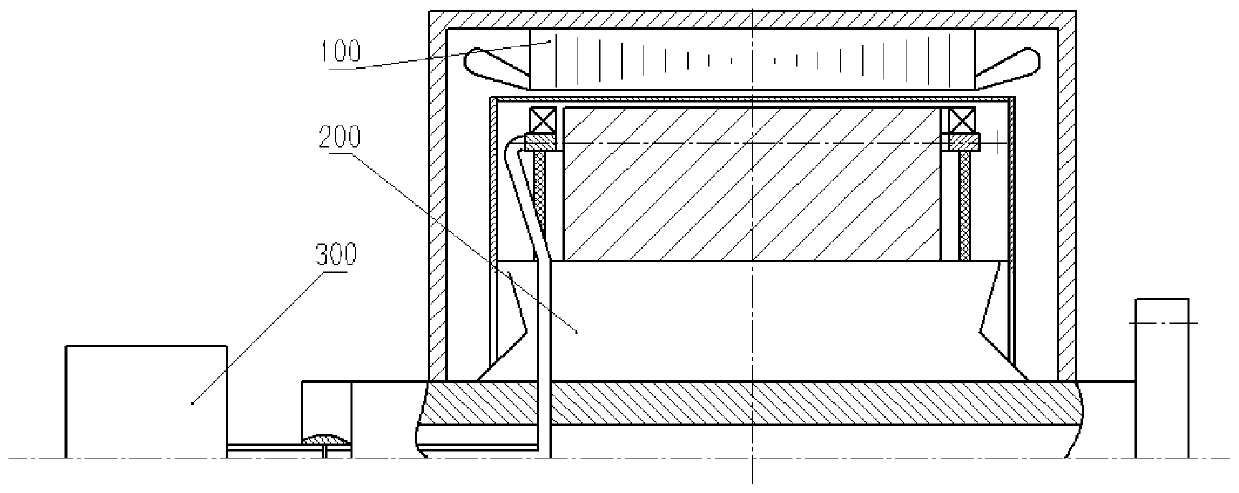

[0029] figure 1 Shown is the general assembly diagram of the wind power motor of the present invention, which is composed of a stator 100, a rotor 200, and a low-temperature cooling system 300 for providing refrigerant.

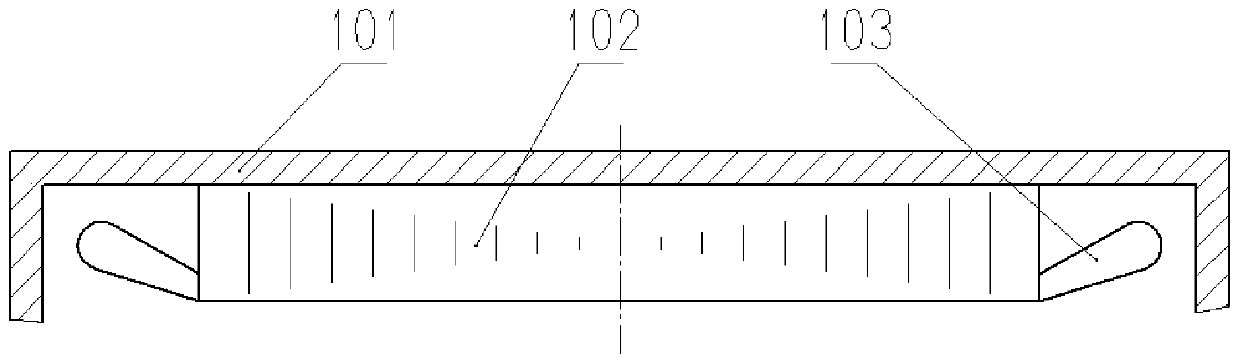

[0030] figure 2 Shown is a schematic structural view of the stator 100 , which consists of a frame 101 , a stator back iron 102 and a stator winding 103 . According to the electromagnetic scheme, the motor adopts an air gap armature structure, which reduces the existence of iron teeth, and is supported by non-magnetic composite materials or stainless steel. The winding 103 adopts single-layer winding, and the wire material adopts Litz wire. The cooling of the stator 100 adopts a water cooling structure.

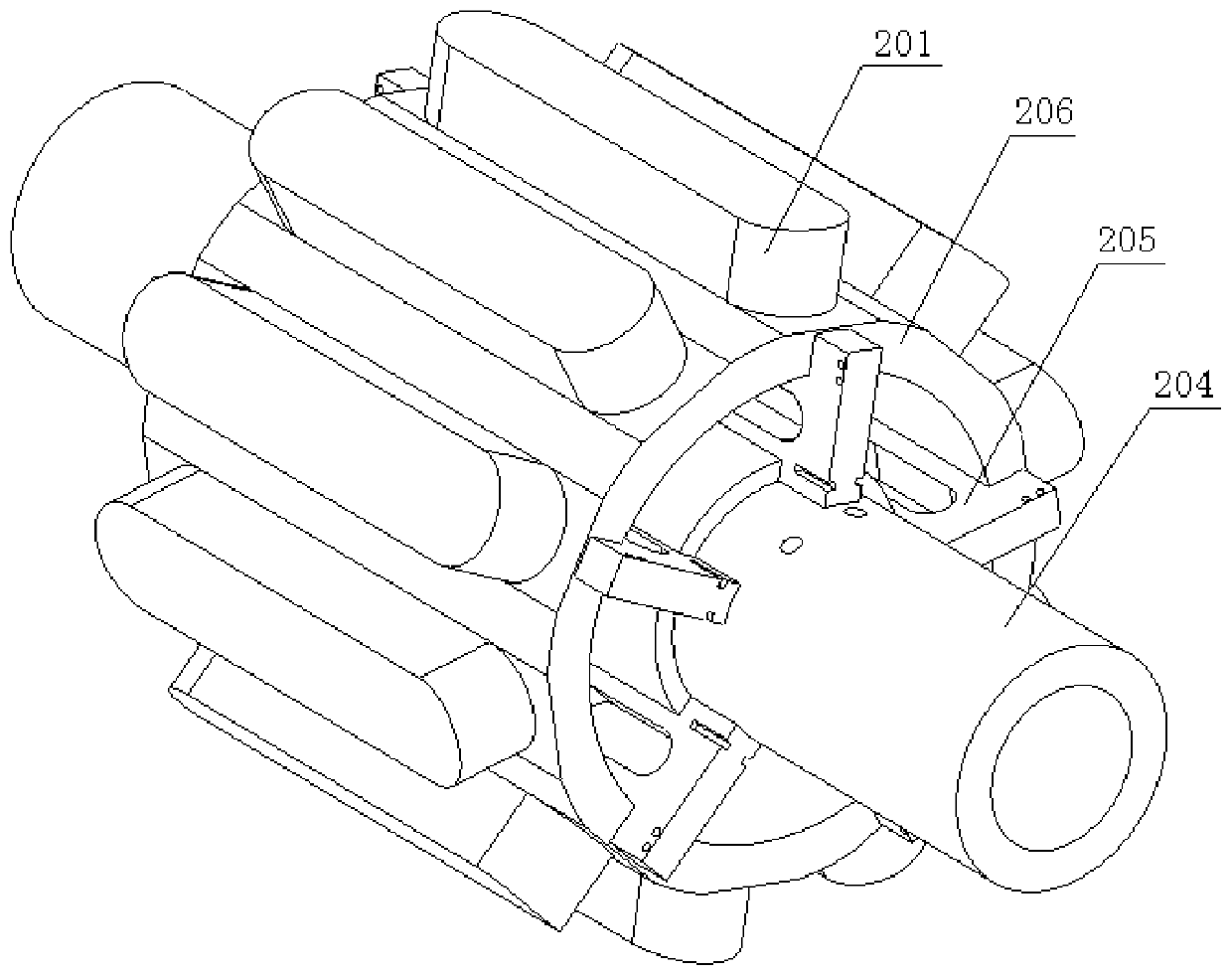

[0031] The rotor 200 includes a normal temperature part and a low temperature part connected to the end of the normal temperature part by means of supporting insulation parts. The connecting part is divided into radial support rods 212 and tangential sup...

Embodiment 2

[0046] The difference from the above-mentioned embodiments is that the stator of this motor adopts the stator of an ordinary AC motor, and iron teeth are used.

Embodiment 3

[0048] The difference from the above embodiments is that the stator of this motor adopts an air-cooled structure, and the stator adopts Robel coils.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com