Filter cloth convenient to clean

A filter cloth and filter layer technology, which is applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of difficult cleaning of the filter cloth, inability to wash the filter cloth multiple times, and slow flow rate of the washing water. Thorough cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

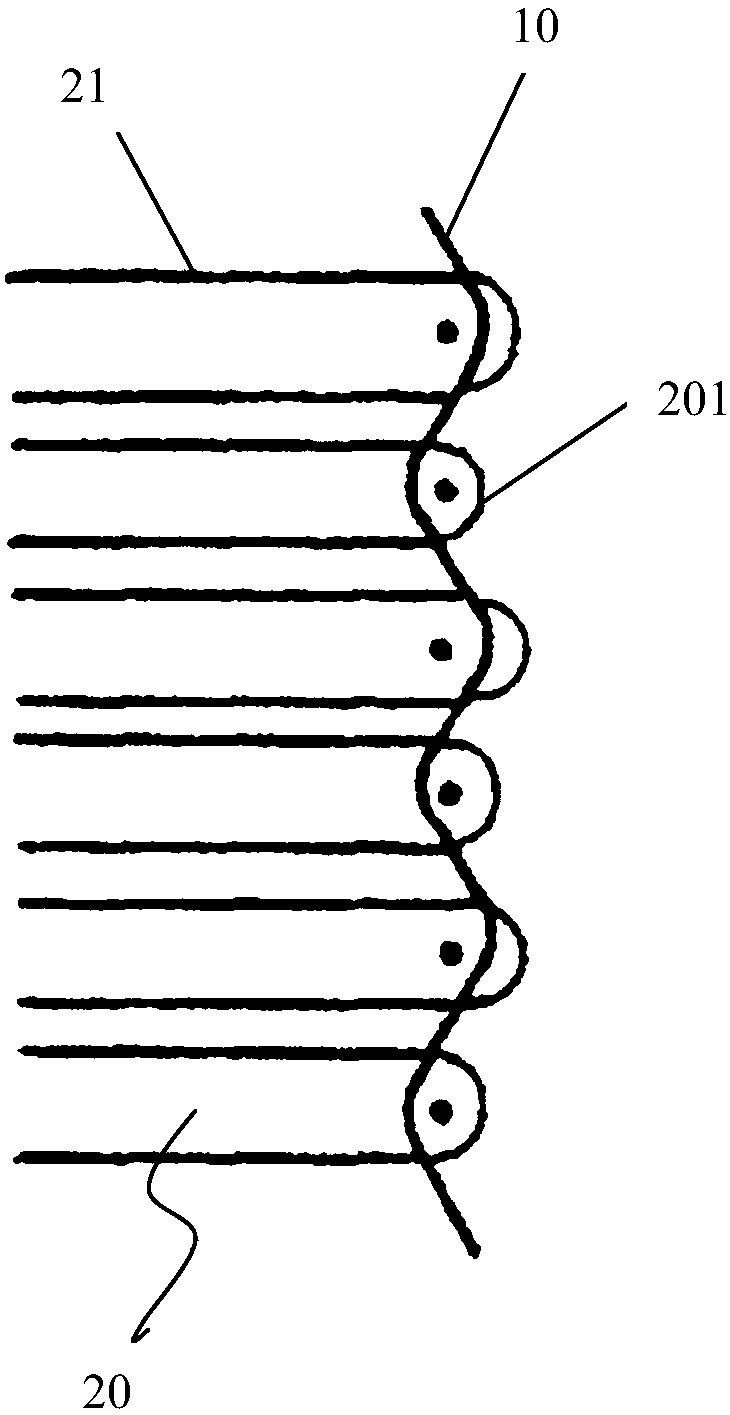

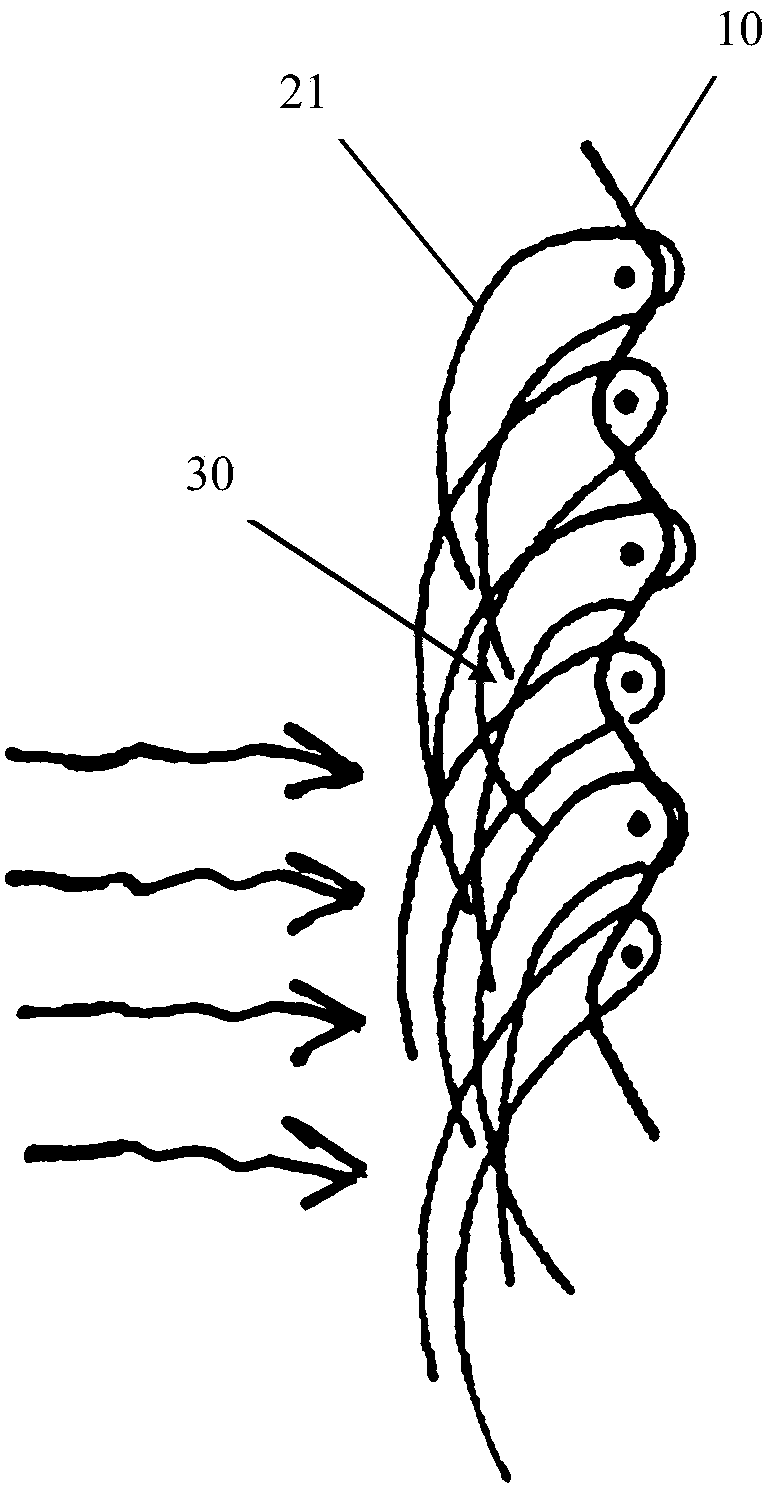

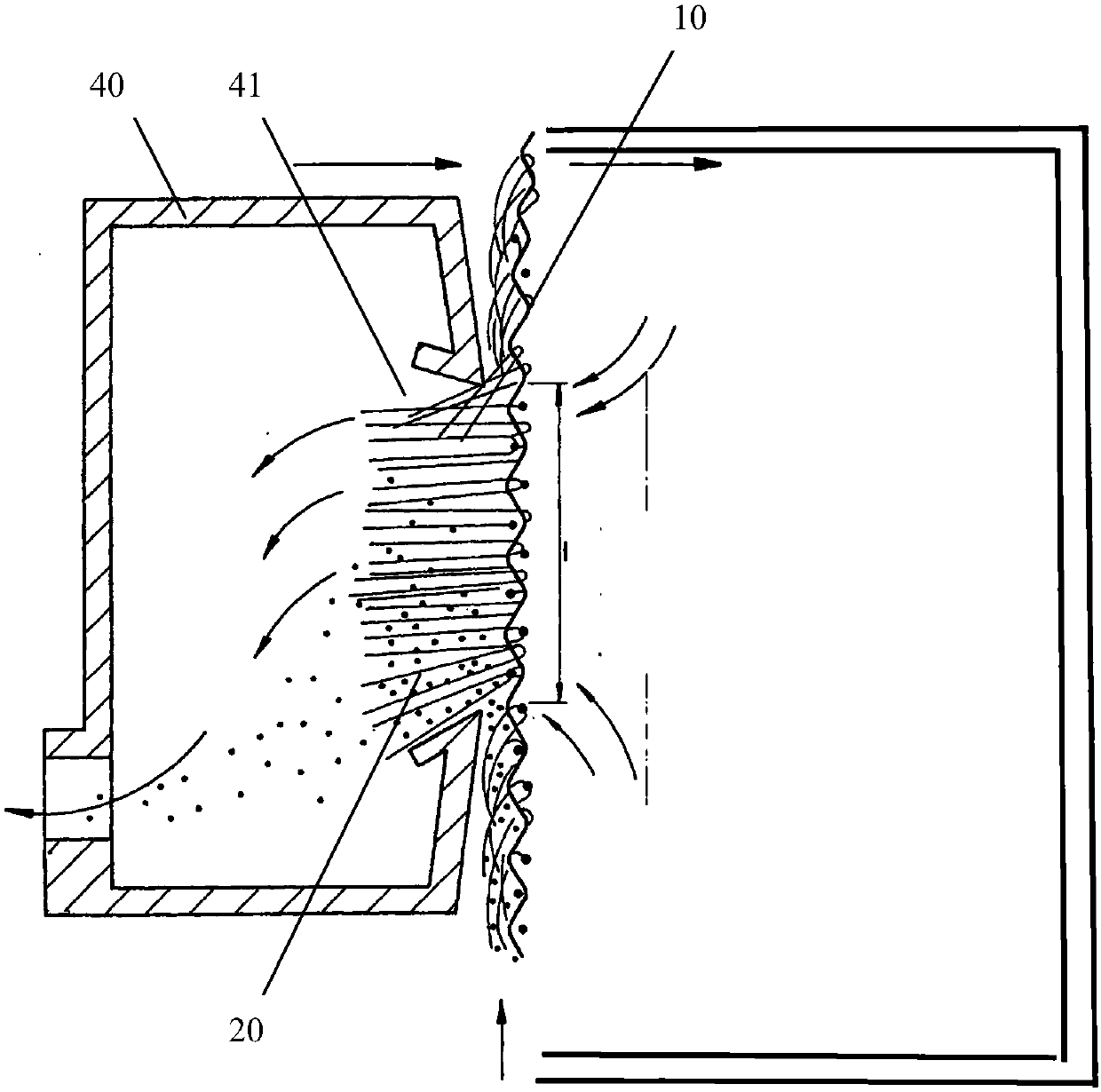

[0027] Please check figure 1 , a kind of filter cloth that is easy to clean, and it comprises support network 10 and is connected to the filter layer 20 on the flushing side of support network 10 (that is to meet the side of filtered water flow); A plurality of velvet filaments 21 on the top, and the plurality of velvet filaments 21 form a plurality of single filaments scattered at their free ends.

[0028] In this embodiment, there is a long-pile filament 201 with a length greater than the length of the velvet filament 21, and the free end of either end of the two ends of the long-pile filament 201 forms the velvet filament 21. The supporting net 10 has a plurality of meshes, and the long-pile filament 201 The silk 201 passes through the mesh and is wound on the support net 10, and the free ends at both ends are exposed outside the support net 10 to form the velvet 21, that is, the free ends at the two ends of the long velvet 201 silk are used as the velvet 21, and each velve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com