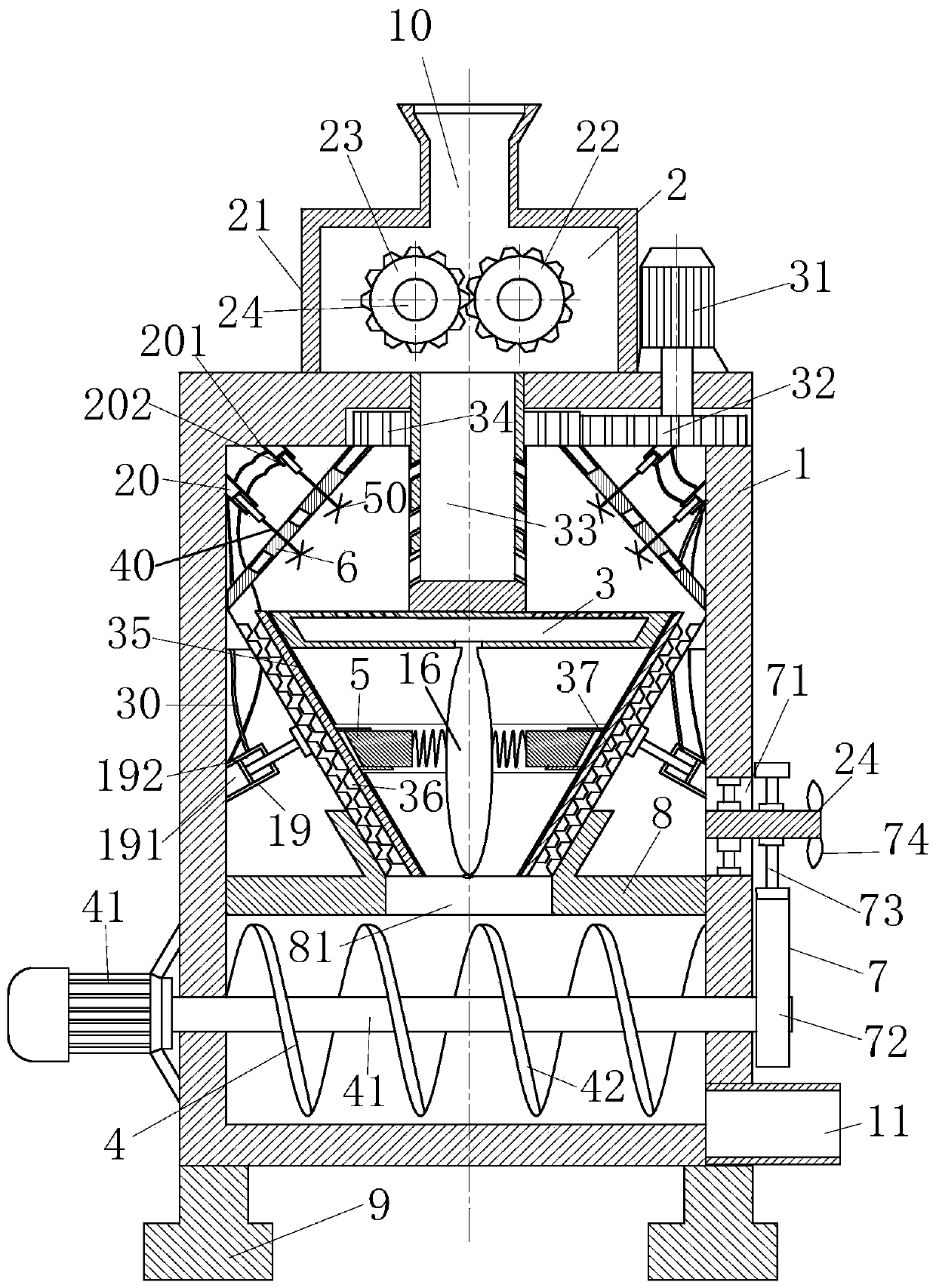

Solid particle chemical raw material crushing recycling device

A solid particle recovery device technology, applied in the direction of grain processing, etc., can solve the problems of blockage of the crushing device, insufficient crushing of granular materials, poor crushing effect, etc., and achieve the effect of easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

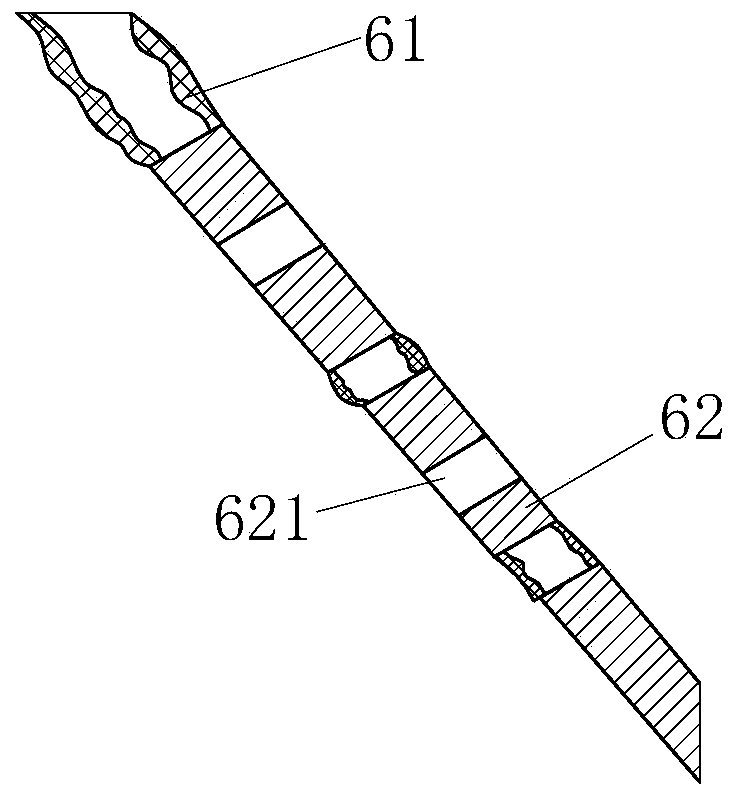

Embodiment approach

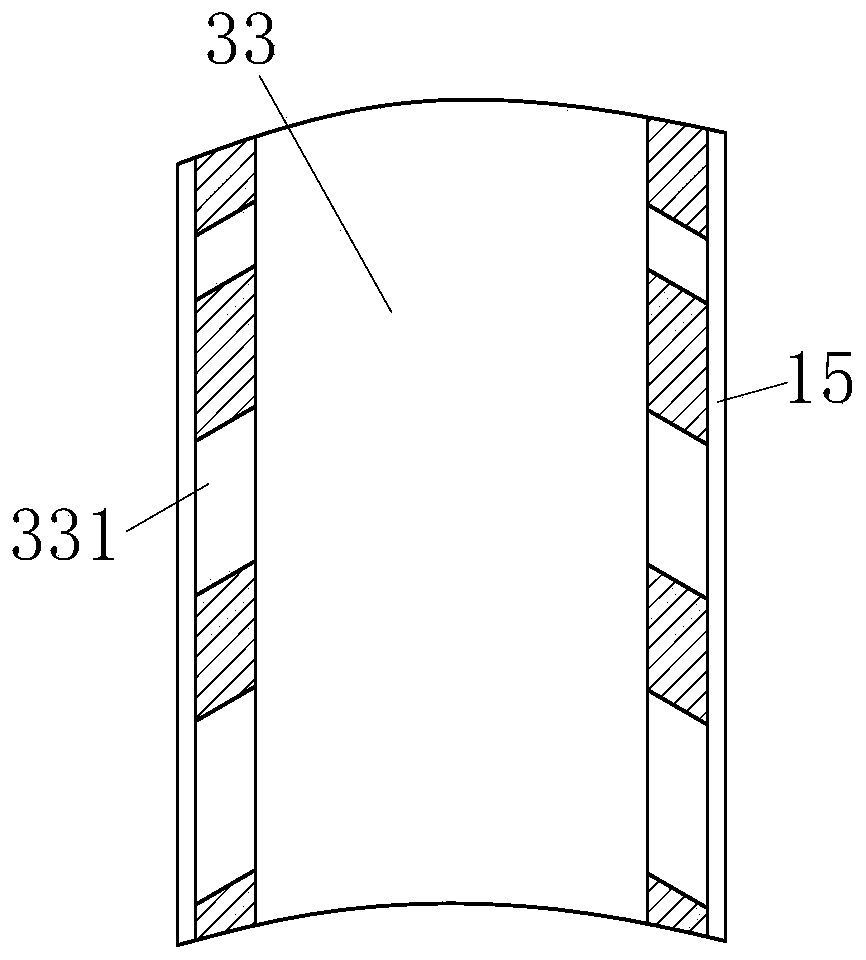

[0035] As an embodiment of the present invention, the outer surface of the hollow rotating shaft 33 is provided with a negative pressure plate 15, and the width of the negative pressure plate 15 is 1 mm. During operation, when the hollow rotating shaft 33 is driven by the first motor 31 to rotate at a high speed, the outer surface of the negative pressure plate 15 arranged on the outside of the hollow rotating shaft 33 will generate friction, and then the outside of the hollow rotating shaft 33 will form a negative pressure zone, and then will The pulverized granular materials collected in the hollow rotating shaft 33 are drawn out from the discharge hole 331 opened on the side of the hollow rotating shaft 33 through the suction force generated by the negative pressure area, so as to prevent the accumulation of the granular materials in the hollow rotating shaft 33 and affect the crushing. The efficiency of the recovery unit.

[0036]As an embodiment of the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com