Pipeline cleaning robot

A robot and pipeline technology, applied in the field of urban water supply and drainage, can solve problems such as dredging personnel safety hazards, sewer pipeline blockage, manual cleaning difficulties, etc., to reduce the risk of downtime for maintenance, prevent garbage entanglement, and improve the effect of cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

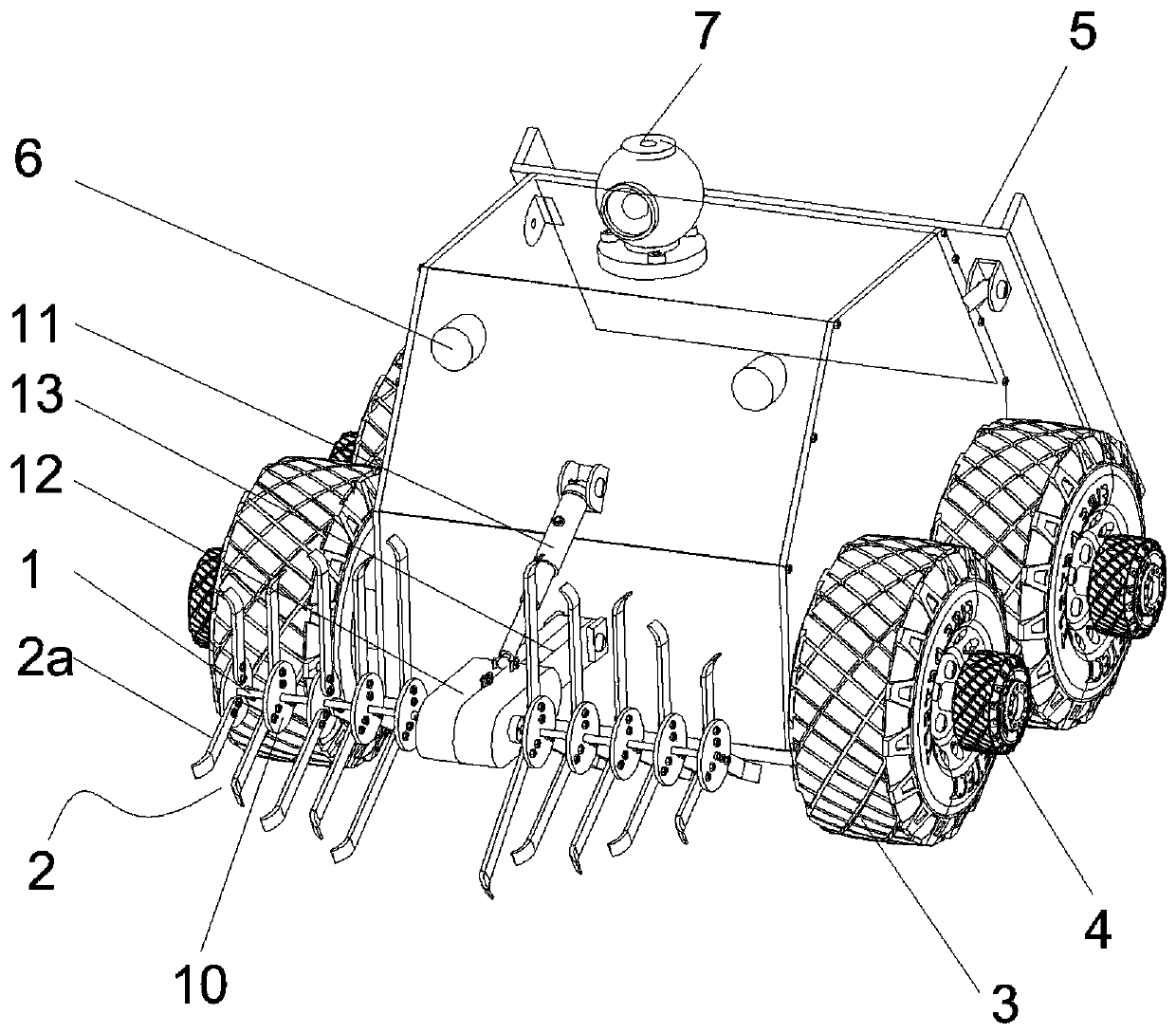

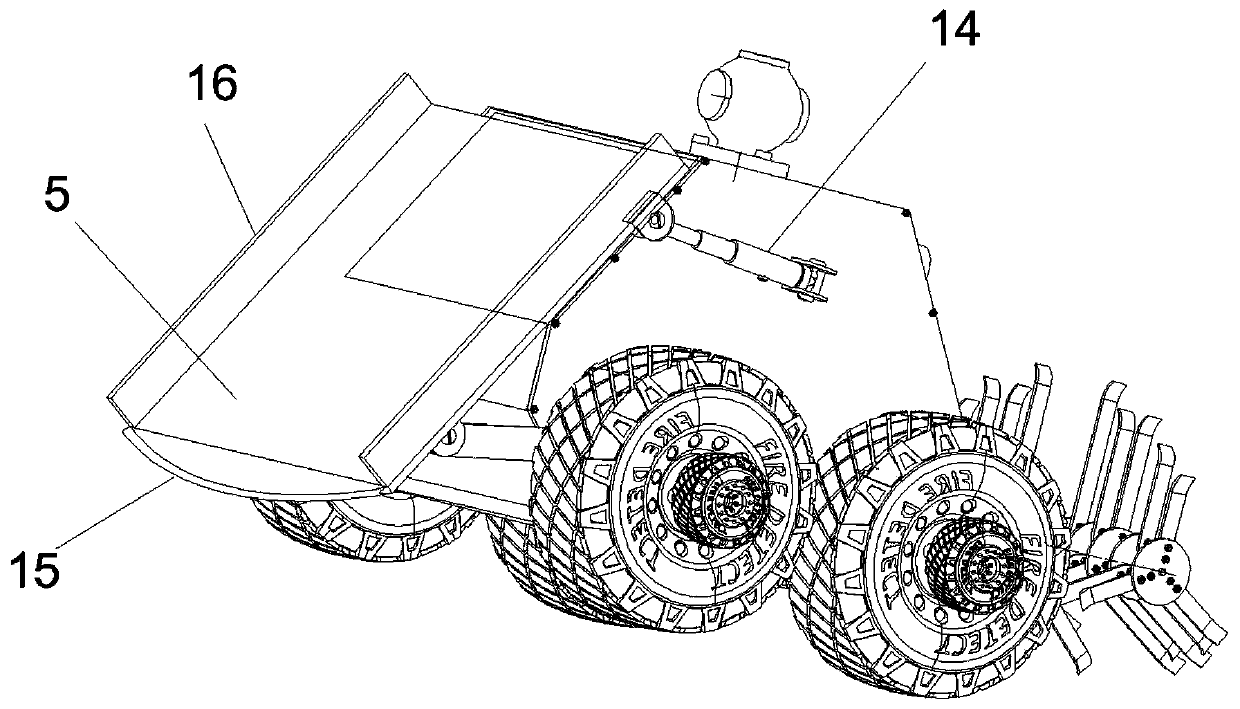

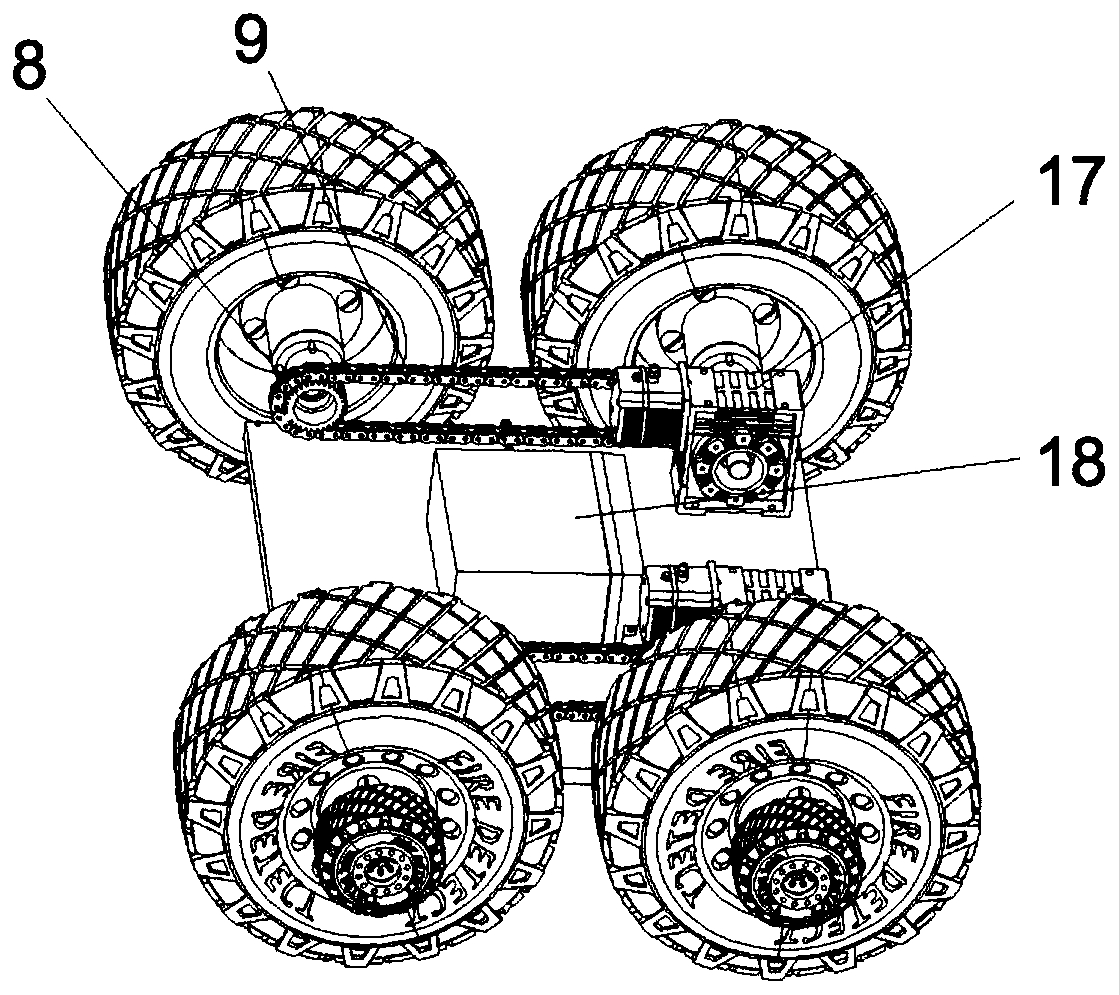

[0026] figure 1 It is a schematic diagram of the isometric structure of the present invention; figure 2 It is a structural schematic diagram of the cleaning plate of the present invention; image 3 Schematic diagram of the powertrain structure; Figure 4 Schematic diagram of the drive wheel structure;

[0027] In this embodiment, the length direction of the vehicle frame assembly is its walking direction, the head of the vehicle frame assembly is on one side of the walking direction along the length direction of the vehicle frame, and the rear part of the vehicle frame assembly is on one side of the backward direction along the length direction of the vehicle frame. side;

[0028] As shown in the figure: it includes the frame assembly, the traveling mechanism installed on the frame assembly and driving it forward or backward, and the dredging mechanism arranged at the head of the frame assembly to dredge the pipeline. The dredging mechanism includes The cutter assembly in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com