Electromagnetic stirring casting device convenient to adjust

An electromagnetic stirring and agitator technology, applied in the field of agitators, can solve the problems of high cost, inability to carry out modular installation and disassembly, low utilization rate of magnetic field, etc., and achieve the effects of low cost of use, wide range of forming alloys, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

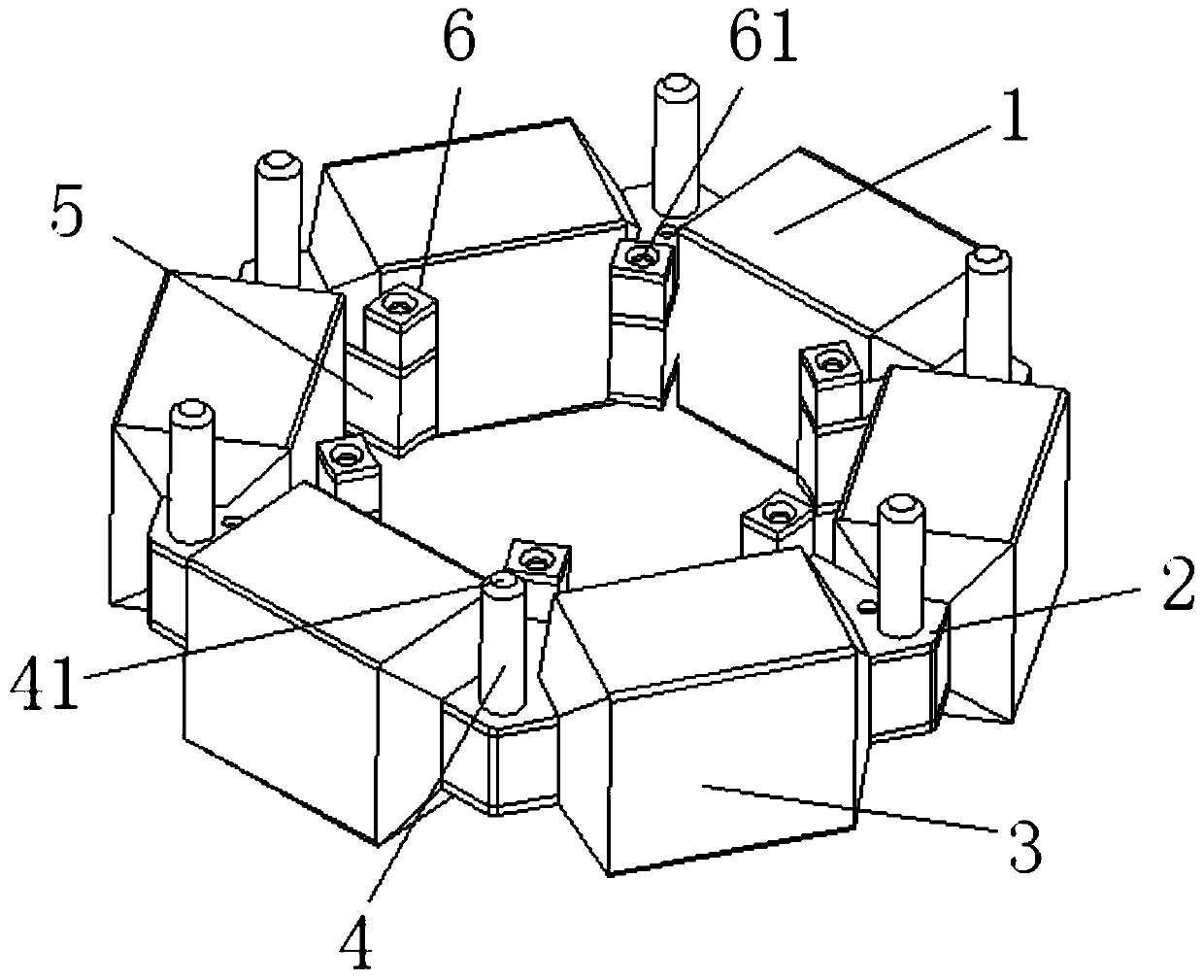

[0022] Embodiment one, with reference to figure 1 , an electromagnetic stirring casting device that is easy to adjust, includes a stirrer body 1, the stirrer body 1 is installed in a water tank 10, the stirrer body 1 contains a main magnetic flux 2, the shape of the main magnetic flux 2 is a regular hexagon, and the main magnetic flux The top of the hexagon 2 is welded with a fixed column 4 at the center, and each main magnetic flux 2 is wound with an electromagnetic stirring coil 3 between adjacent fixed columns 4, and the inner side of the main magnetic flux 2 is connected with the A plurality of salient poles 5 are arranged at the corresponding position of the fixed column 4, and the plurality of salient poles 5 are integrally superimposed with the main magnetic flux 2. When the device is in use, the electromagnetic stirring coil 3 is electrically connected to the external power supply through wires , the power on or off of the electromagnetic stirring coil 3 can be control...

Embodiment 2

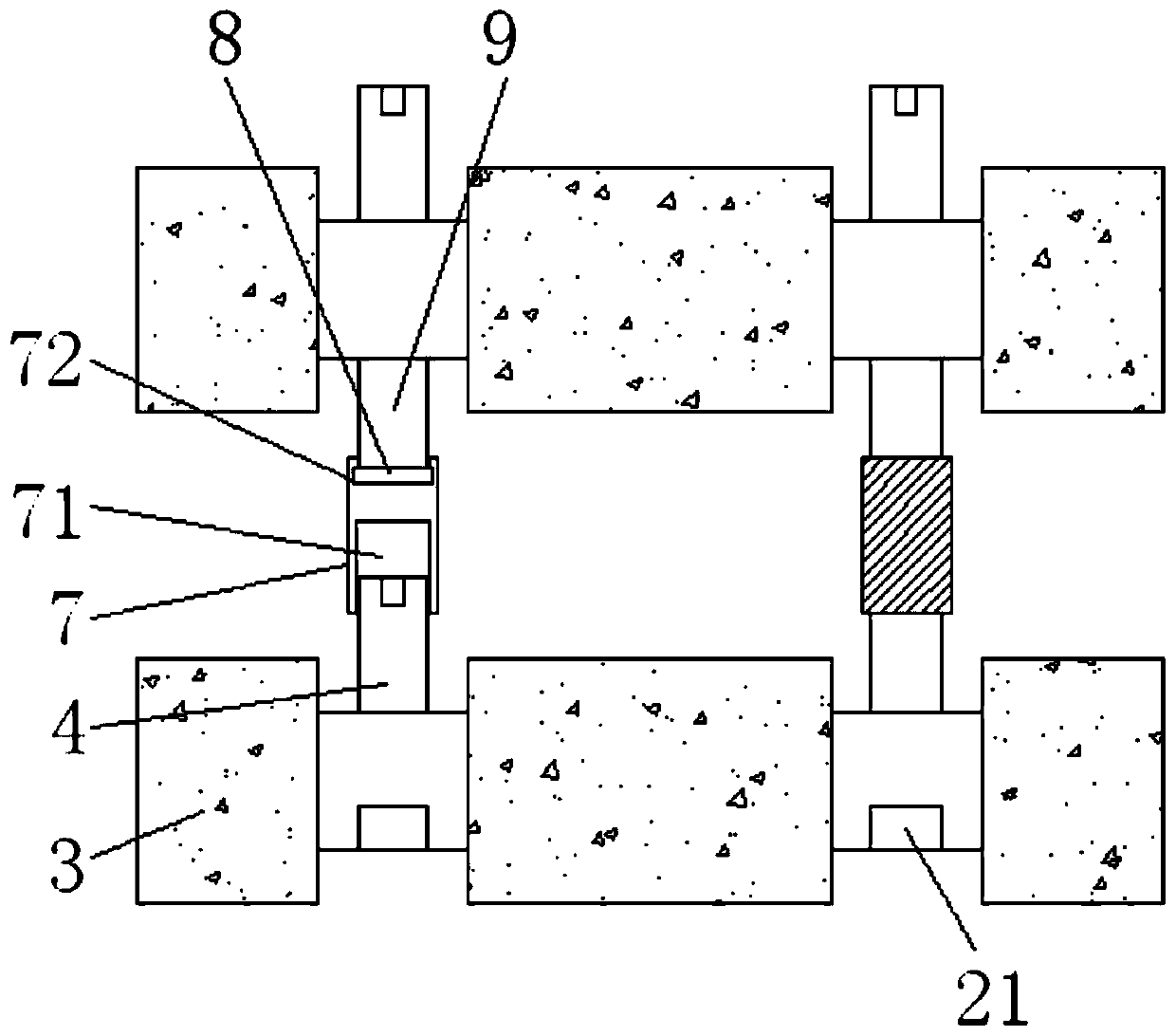

[0023] Embodiment two, refer to figure 2 , the tops of the plurality of salient poles 5 are fixed with reinforcing poles 6, and the center of the tops of the reinforcing poles 6 is provided with a connection hole 61, the inner sides of the plurality of salient poles 5 and the reinforcing poles 6 are smooth arc structures, and the fixing columns 4 The top of the control rod 7 is threadedly connected with a control rod 7, and the bottom of the control rod 7 is provided with a threaded column hole 71 threadedly connected with the fixed column 4, and the other end is provided with a circular groove 72, and the circular groove 72 is rotated and embedded with a round block 8, and the round block 8 is welded with a straight rod 9 at the center of the top, and the other end of the straight rod 9 extends to the outside of the control rod 7, and the bottom of the main magnetic flux 2 is provided with a threaded hole 21 corresponding to the fixed column 4. When using the device At this ...

Embodiment 3

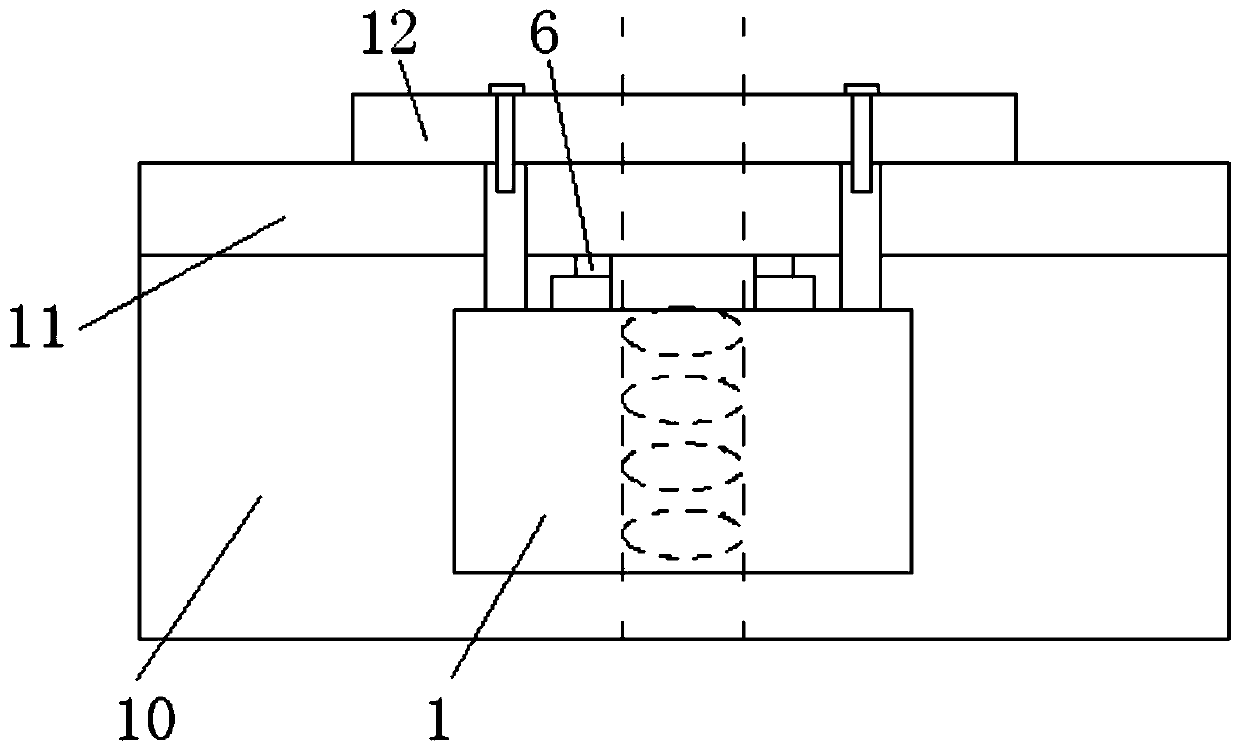

[0024] Embodiment three, refer to image 3 The top of the water tank 10 is detachably connected with a tank cover 12, and the tank cover 12 is detachably connected with the fixing column 4 by screws. The nail is connected with the reinforcement pole 6, and the electromagnetic stirring coil 3 is provided with a plurality of them. The top center of the fixed column 4 is provided with a threaded nail hole 41. The threaded nail hole 41 can facilitate the detachable connection between the fixed column 4 and the case cover 12. When the device is installed, the reinforcement pole 6 will be connected to the top plate 11, so that the device is stably located in the water tank 10, and the inner connection lines of a plurality of electromagnetic stirring coils 3 form a regular hexagon that does not exceed the salient pole 5, which can reduce the occupied space. The processing space of molten metal can be increased and the cost can be reduced.

[0025] Working principle: The electromagne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com