A belt-type grinding device for a metal belt and a belt-type grinding method for the metal belt

A metal belt and grinding belt technology, which is applied to the parts of grinding machine tools, abrasive belt grinders, metal processing equipment, etc., can solve the problems of reduced productivity and failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

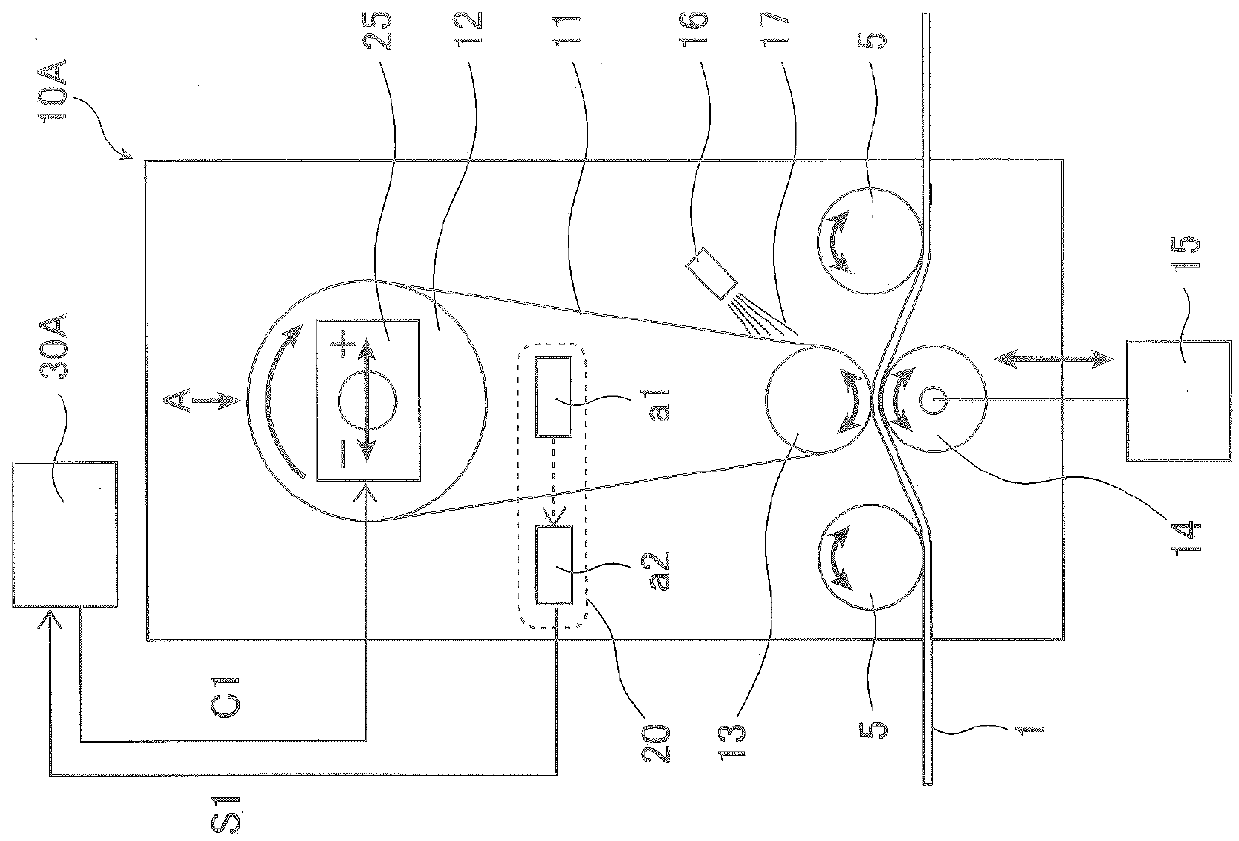

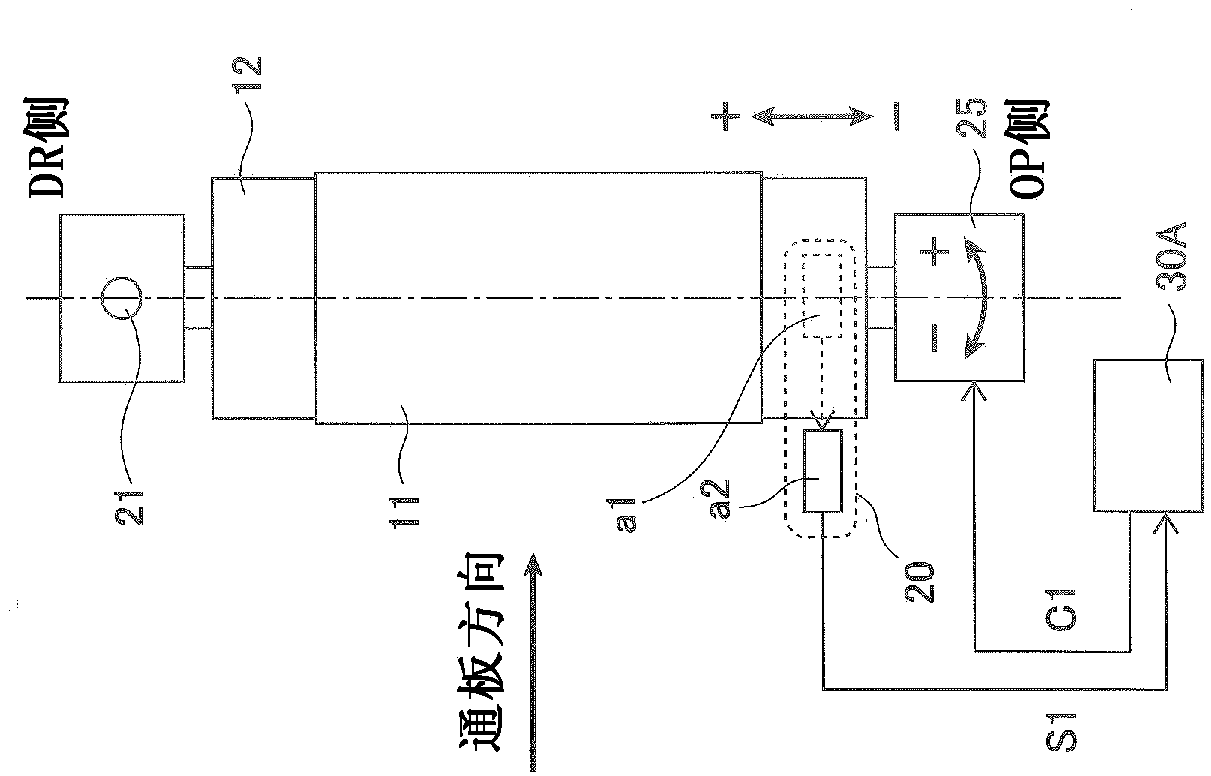

[0066] As a first embodiment of the present invention, for example, figure 1 10 A of belt grinding apparatuses of the form shown. figure 1 It is a schematic diagram (side view) of the belt grinding apparatus 10A viewed from the operation side (OP side), figure 2 is shown from figure 1 A view of the vicinity of the idler roller 12 observed in the direction of the arrow A.

[0067] figure 1 The belt grinding device 10A shown has: a rotating grinding belt 11, which grinds the entire surface of the metal belt 1 in the pass-through plate; a belt reciprocating actuator 25, which makes the above-mentioned grinding belt 11 grind on the above-mentioned metal belt. The belt 1 reciprocates in the plate width direction; and the edge detection sensor 20 detects the edge of the grinding belt 11 in the width direction. It should be noted that, in figure 1 The belt grinding apparatus 10A shown, with Figure 7 The same numbered components of the belt grinding device 10 shown play th...

no. 2 approach

[0081] The inventors of the present invention have further conducted detailed studies on the above-mentioned belt grinding apparatus 10A, and obtained the following findings. That is, as the cause of local abnormal heat generation that causes a fire accident in the grinding operation, (i) a grinding belt is generated due to a sudden failure of the above-mentioned end detection sensor or the above-mentioned belt reciprocating actuator, etc. In the case of poor movement control in the width direction of the grinding belt deviated from the specified reciprocating movement area, the end of the grinding belt in the width direction contacts the surrounding equipment and generates local abnormal heat; (ii) due to the deterioration of the grinding belt On the other hand, folds are generated at the ends in the width direction of the grinding belt (or cracks formed inside the ends in the width direction), and as a result of local thickening, the contact pressure at this part increases an...

Embodiment

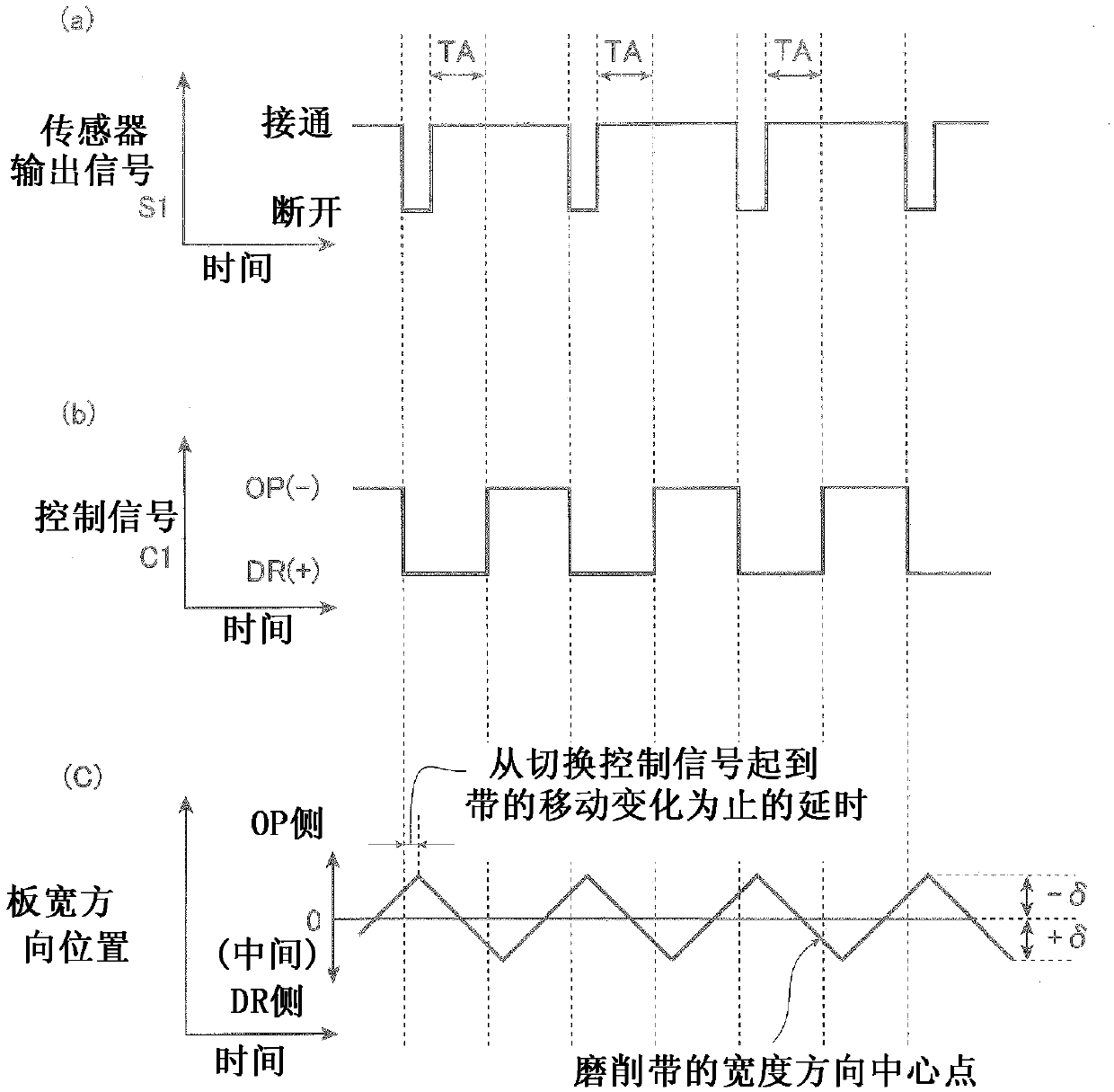

[0094] use instead Figure 7 The belt grinding device 10 is formed figure 1 The continuous grinding production line of the belt grinding device 10A shown in the figure passes 20,000 to 30,000 tons of ferritic stainless steel hot-rolled steel strips with a plate thickness of 1.5 to 13 mm and a plate width of 700 to 1600 mm. Do grinding work. image 3 The δ is set to 50mm. As a result, control can be automatically performed to keep the center of the grinding tape in the width direction near the center position of the metal tape in the width direction during grinding. And, with the use of Figure 7 Compared with the situation of the continuous grinding production line, it can reduce the fire accidents in the grinding operation. However, in the continuous grinding production line using the belt grinding device 10A, the number of fire accidents during the grinding work due to deterioration of the grinding belt and poor control of movement in the width direction of the grinding b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com