Safety charging gun

A charging gun and safety technology, applied in the field of charging guns, can solve problems such as inconvenient use, potential safety hazards, insufficient heat dissipation, etc., and achieve the effects of protecting personal safety, good heat dissipation performance, and a good sense of experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

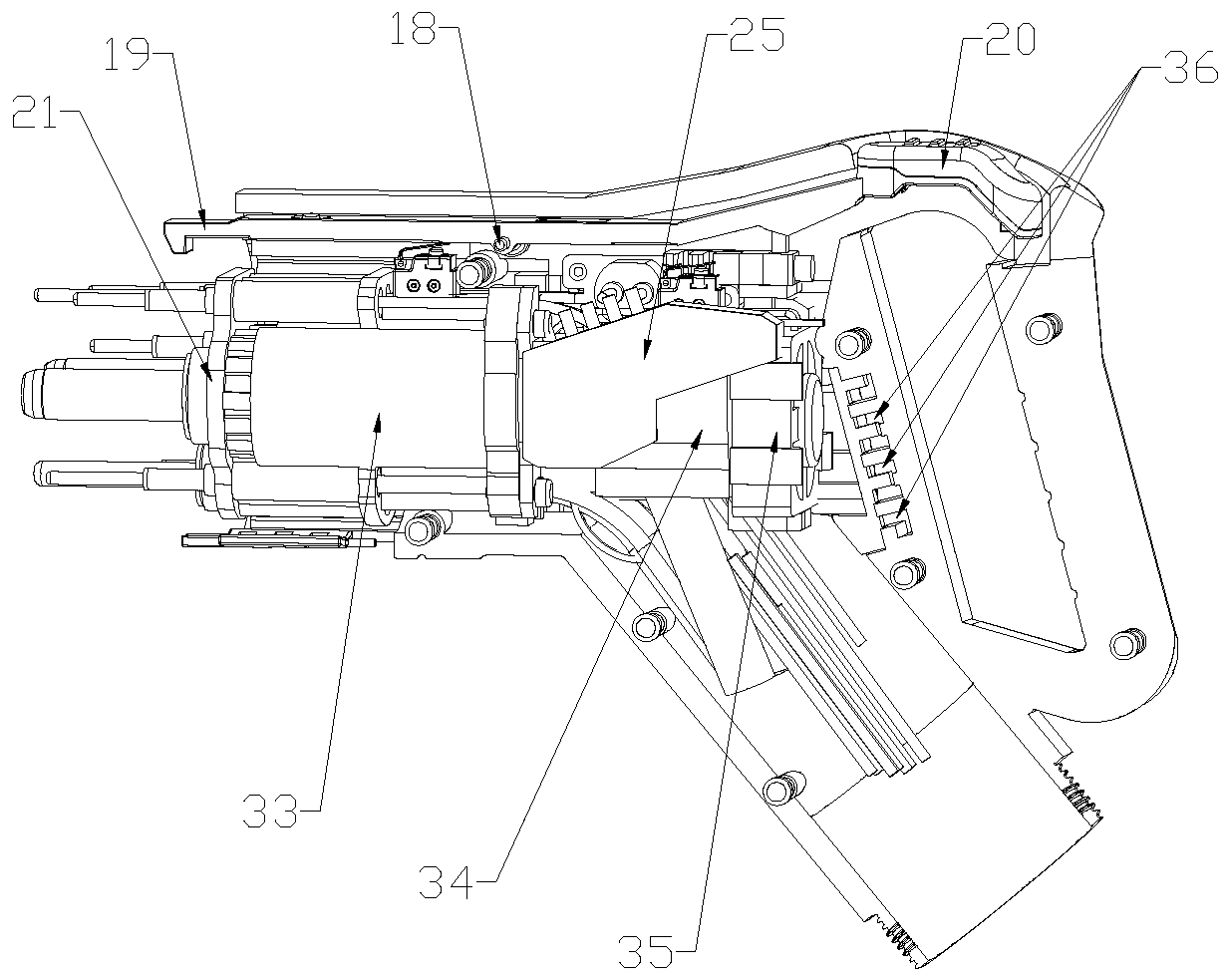

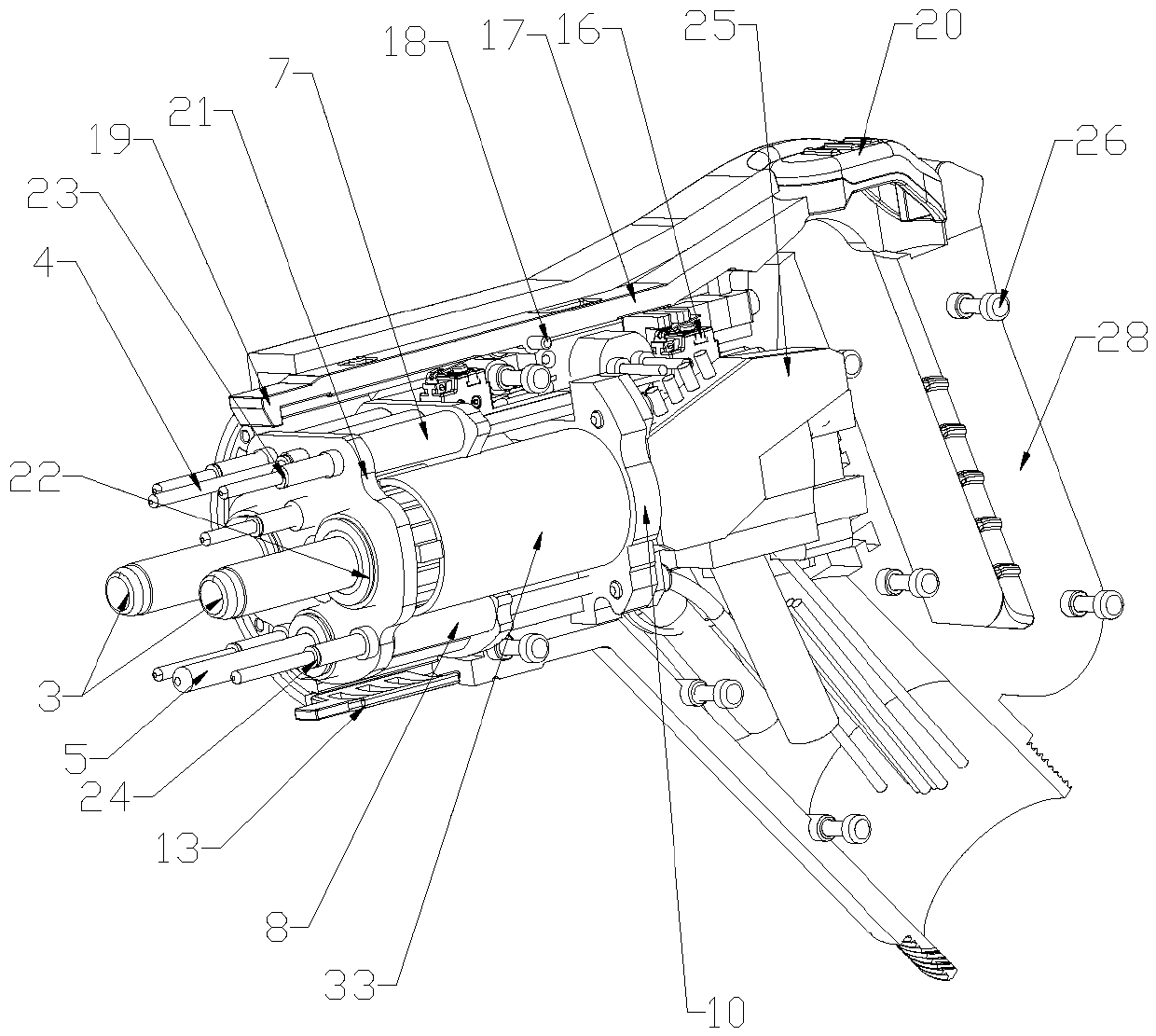

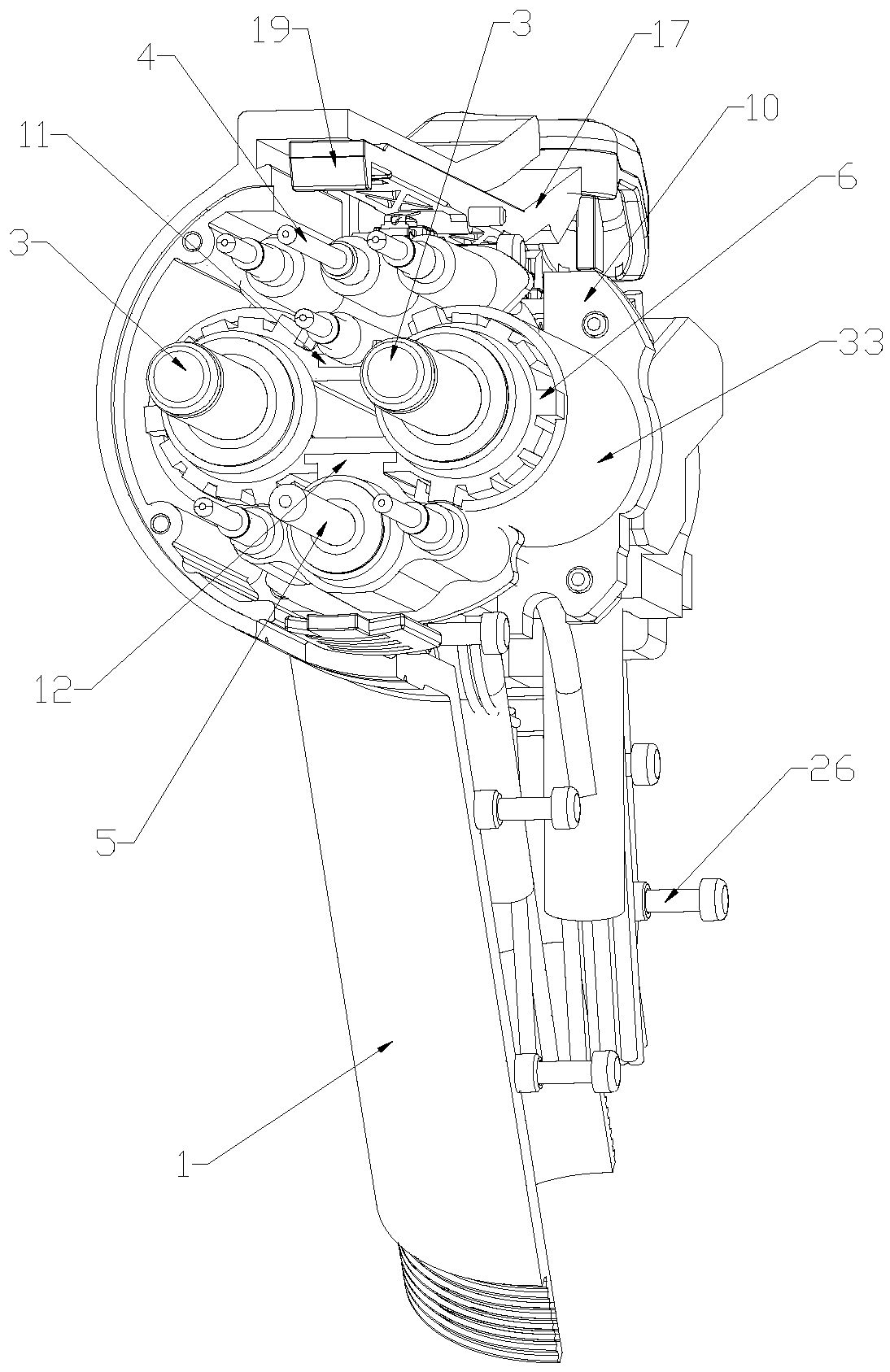

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0028] Such as Figure 1 to Figure 9 As shown, in this embodiment, a safety charging gun includes a first housing 1, a second housing 2, a power terminal 3, a signal terminal 4, a ground wire terminal 5, a cooling block 6, a signal bracket 7, and a ground wire bracket 8. Terminal plug 9, fixed block 10, air guide safety cover 33, air guide groove 34, heat dissipation fan 35, conductive rubber block 39 and thermal sensor 38, the power terminal 3 runs through the heat dissipation block 6, and the signal terminal 4 runs through the signal bracket 7, the ground wire terminal 5 runs through the ground wire bracket 8, the signal bracket 7, the ground wire bracket 8 and the heat sink 6 are all located inside the terminal plug 9, The signal terminal 4, the ground wire terminal 5 and the power terminal 3 al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com