Production system and production method of biochar-based coated nitrogen fertilizer

A technology of coating nitrogen fertilizer and production system, applied in the field of agricultural biomass resource utilization, can solve the problems of aggravating fertilizer waste and loss, low utilization rate of chemical fertilizer, reducing fertilizer efficiency, etc., and achieves increasing soil organic matter, better slow release effect, achieve a slow release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

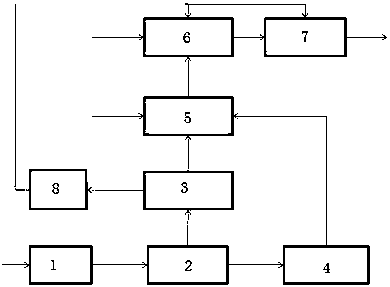

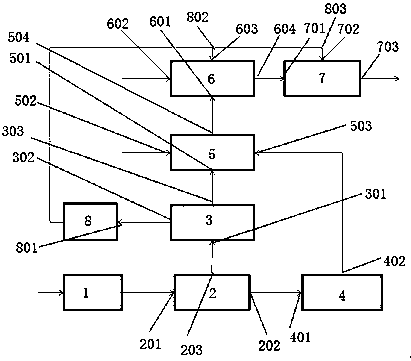

Method used

Image

Examples

Embodiment 1

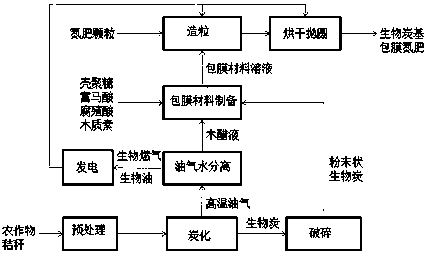

[0065] Embodiment 1: The agricultural and forestry biomass raw material in this embodiment is crop straw, including corn straw, wheat straw, rice straw and soybean straw; a production system of biochar-based coated nitrogen fertilizer according to the present invention produces biochar-based bag The method for membrane nitrogen fertilizer specifically comprises the following steps.

[0066] (1) Pretreatment: The crop straw is sent to the pretreatment system to be crushed to 10-20cm.

[0067] (2) Carbonization: send the crushed crop straw in step (1) to a carbonization furnace for carbonization, wherein the carbonization temperature is 600°C, and the carbonization time is 40 minutes to obtain biochar and high-temperature oil and gas, which are transported to Oil, gas and water separation system, the biochar is transported to the crushing device through the screw discharger.

[0068] (3) Oil-gas-water separation: The high-temperature oil and gas obtained in step (2) are sent to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com