Energy recycling device for vehicle

An energy recovery device and vehicle technology, applied in the direction of control devices, auxiliary drive devices, mechanisms for generating mechanical power, etc., can solve the problem of increasing the impact of the mover and the moving mechanical components of the speed increaser, the difficulty of lubrication and cooling of the speed increaser, and the suspension Poor reliability and other issues, to achieve the effect of compact structure, eliminating the need for lubrication and cooling systems, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to better understand the present invention, the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0067] Such as Figure 1 to Figure 18 As shown, this embodiment provides an energy recovery device for a vehicle, the vehicle includes: a pull arm, a generator and an on-board battery;

[0068] The generator is connected to the vehicle battery;

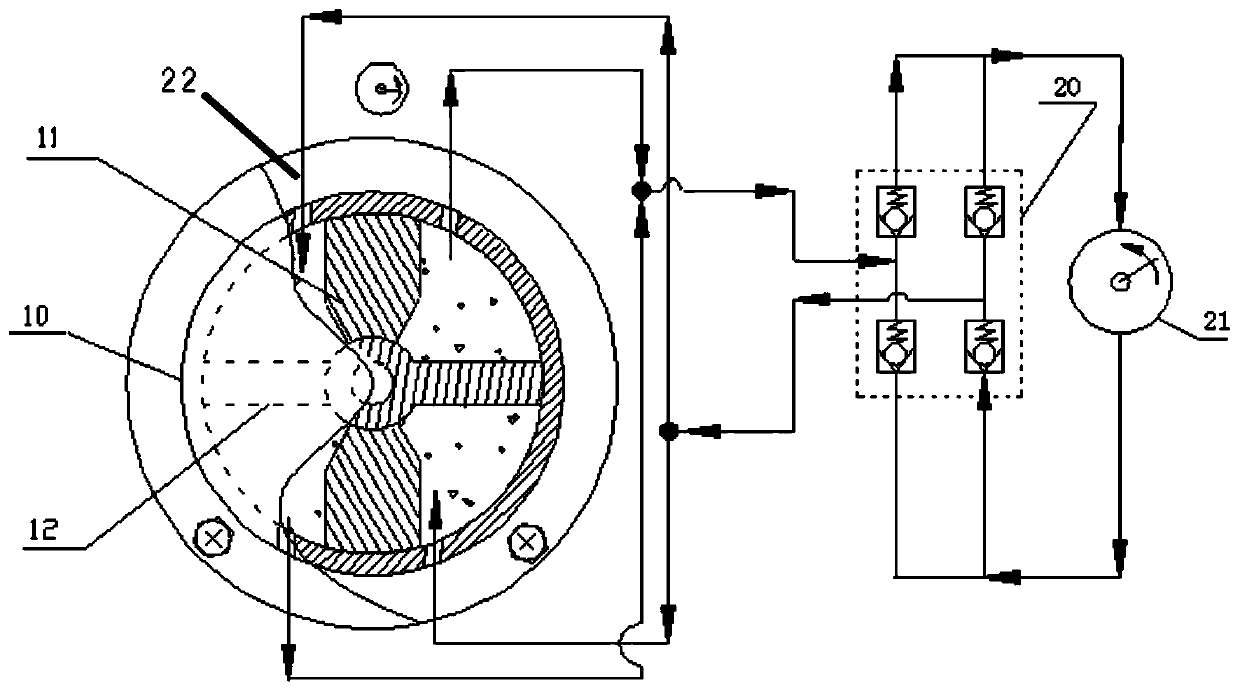

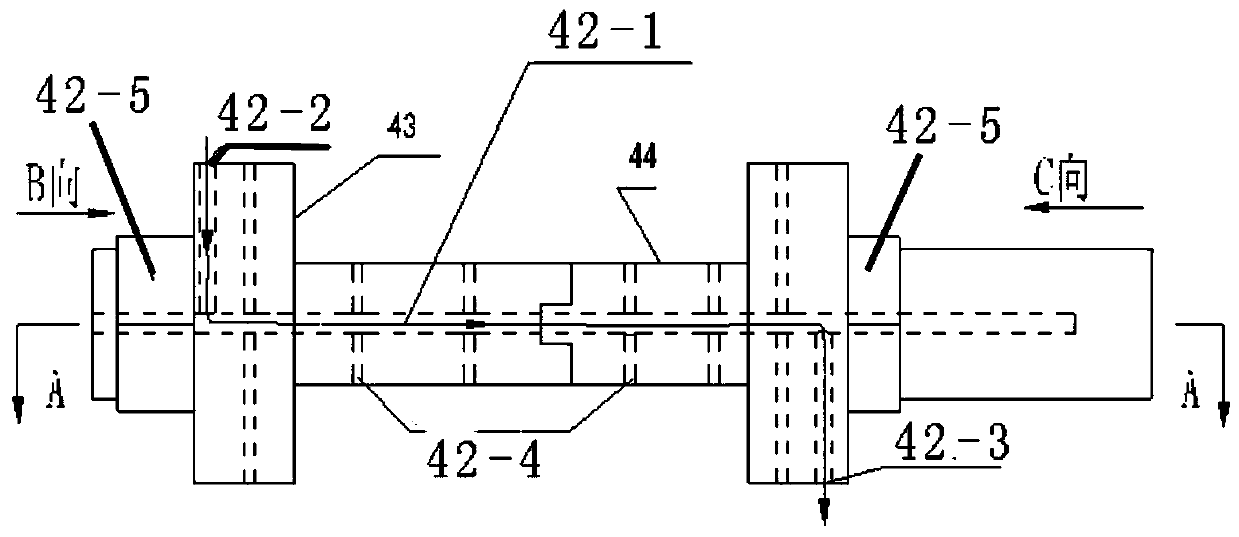

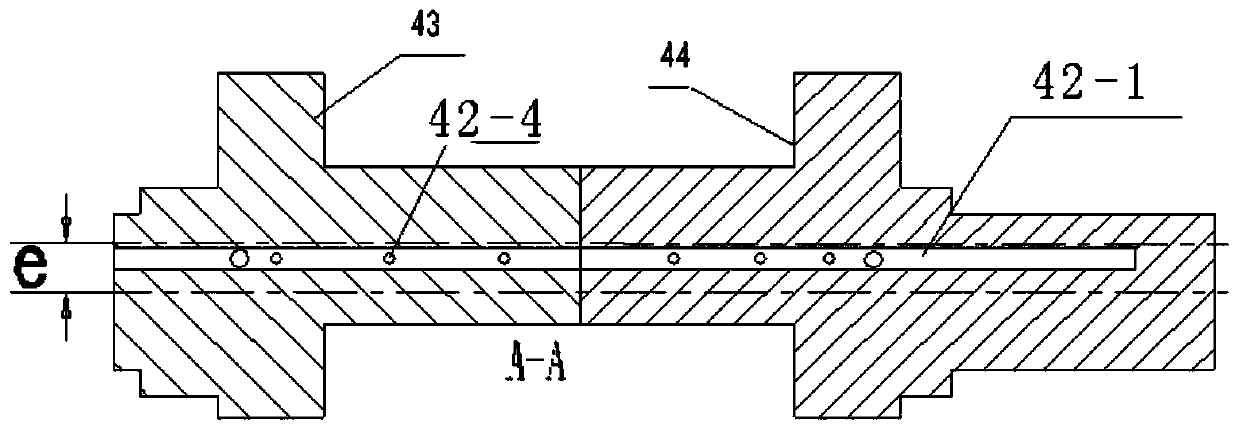

[0069] The energy recovery device includes: a hydraulic shock absorber 22, a hydraulic commutator 20 and a hydraulic speed increaser 21, and the hydraulic shock absorber 22, the hydraulic commutator 20 and the hydraulic speed increaser 21 are sequentially connected to form a hydraulic drive circuit;

[0070] The hydraulic speed increaser 21 is fixedly connected with the generator;

[0071] The hydraulic shock absorber 22 is fixedly connected to the pull arm;

[0072] The hydraulic shock absorber 22 includes: a throttle hole, a seal and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com