Intelligent vibration acceleration sensor base

A technology of vibration acceleration and sensor, which is applied in the direction of measuring acceleration, speed/acceleration/shock measurement, speed/acceleration/electric shock meter detailed information, etc. It can solve the problems of cumbersome measurement accuracy and improve inspection efficiency and reduce procurement Cost, installation method and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

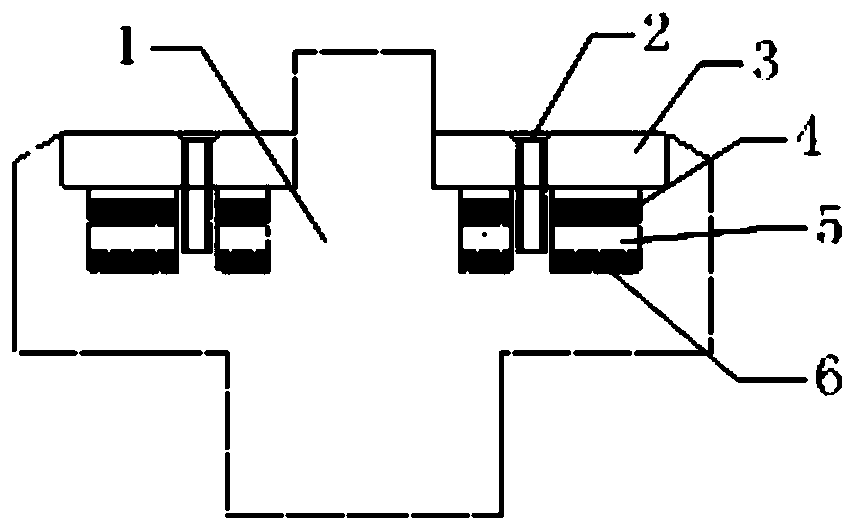

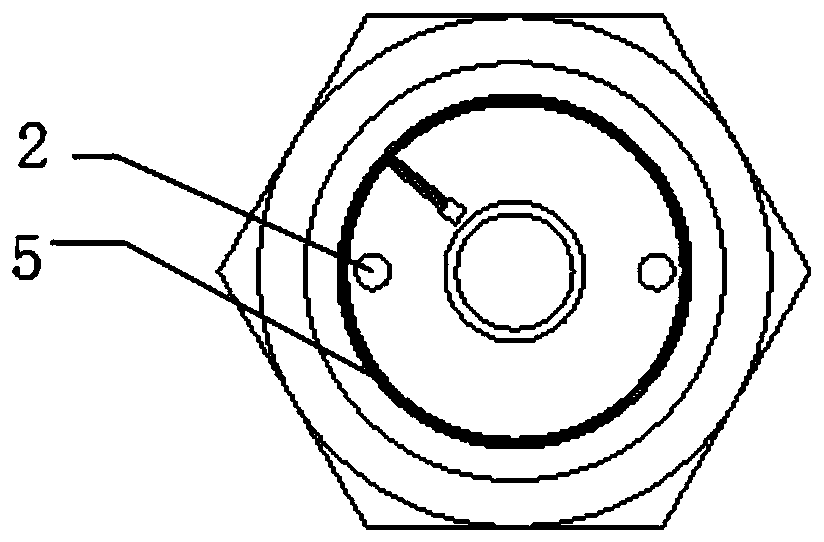

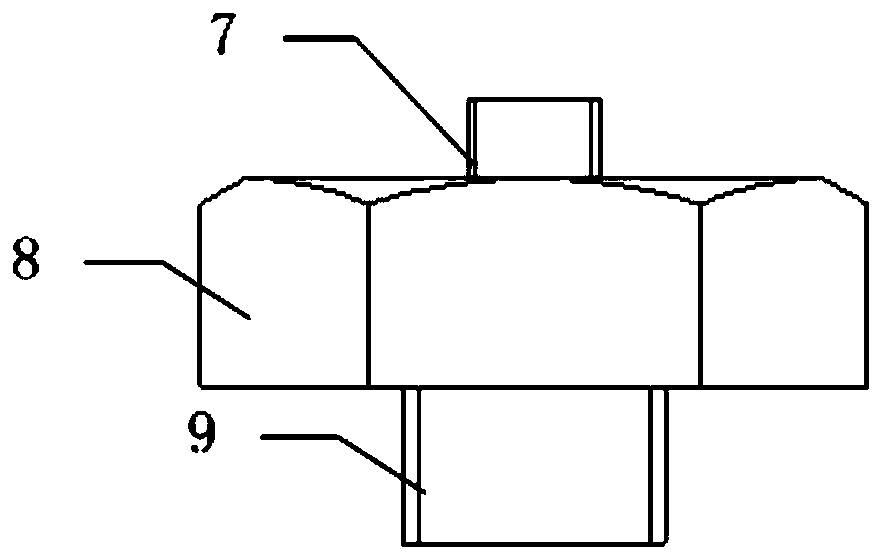

[0031] Such as Figure 1 to Figure 3 As shown, an intelligent vibration acceleration sensor base mainly includes a sensor base block 1, mounting screws 2, ceramic cover plate 3, filling coating 4, and RFID electronic tag module 5. The sensor base block 1 includes its structural main body 8, the upper stud 7 connected with the acceleration sensor and the lower stud 9 connected with the device. The ceramic cover plate 3 is combined with the sensor base block 1 through the mounting screws 2 and the sealant, and is made of ceramic material for the convenience that the radio frequency signal of the electronic label module can be transmitted. The RFID electronic tag module 5 is installed on the bottom of the sensor base block 1 through the bottom insulating gasket 6 , and then sealed and fastened through the filling coating 4 .

[0032] Such as Figure 4 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com