Equipment for cutting metal pipes

A metal pipe and equipment technology, applied in the field of metal pipe cutting equipment, can solve the problems of inability to adjust the cutting length, cumbersome operation, and lack of fixed-length functions, and achieve the effects of easy traction, improved flexibility, and easy movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

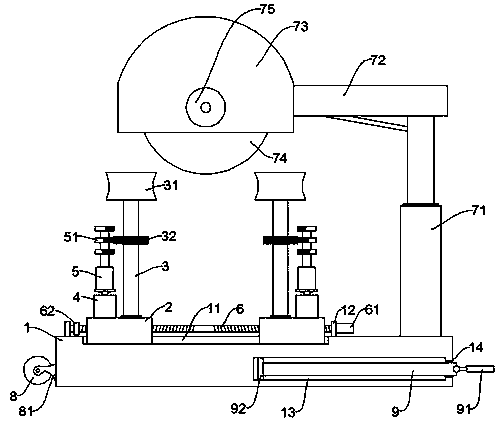

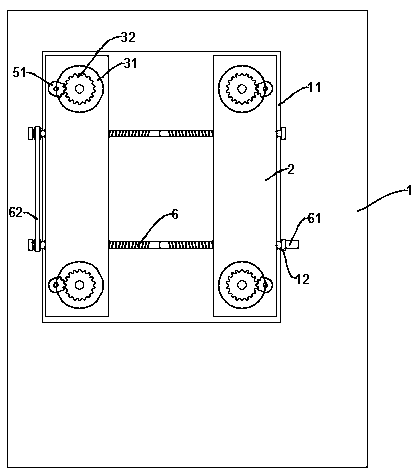

[0023] see Figure 1~2 , in an embodiment of the present invention, a metal pipe cutting device includes a cutting assembly for cutting the pipe and a clamping assembly for clamping and transporting the pipe, both the cutting assembly and the clamping assembly are arranged on a base 1; The cutting assembly includes a second lifting rod 71 and a cutting knife 74, the second lifting rod 71 is installed on the base 1, a connecting frame 72 is fixed on the top of the movable end of the second lifting rod 71, and a protective shell is connected to the end of the connecting frame 72 73, the cutting knife 74 rotates and connects the protective shell 73, and the cutting motor 75 that drives the cutting knife 74 to rotate is installed on the protective shell 73. During work, the cutting knife 74 is driven by the cutting motor 75 to rotate, and the second elevating rod 71 drives the cutting The knife 74 lifts to complete the cutting of the pipeline;

[0024] The clamping assembly inclu...

Embodiment 2

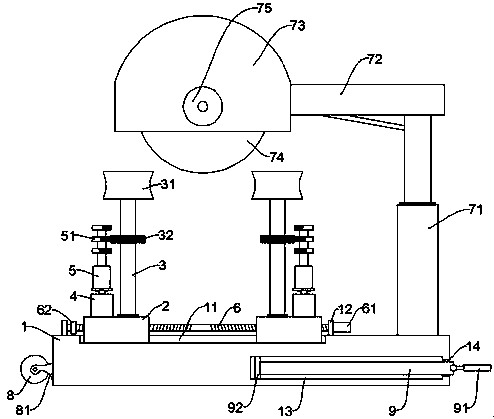

[0030] see Figure 3-4 , the embodiment of the present invention is improved on the basis of embodiment 1, mainly to improve the overall flexibility of use, specifically:

[0031] One side of the base 1 is provided with a roller 8, the roller 8 is rotatably connected to the roller bracket 81 fixed on the base 1, and the lower surface of the roller 8 is higher than the lower surface of the base 1, so that in normal working condition, the roller 8 will not Contact with the ground will not affect the stability of the equipment, and when the equipment needs to be moved, just tilt the base 1 so that the rollers 8 are in contact with the ground;

[0032] Optionally, a pull rod 9 is also included. The pull rod 9 is arranged on the side of the base 1 opposite to the roller 8. A handle 91 is hinged on the pull rod 9. When moving, the pull rod 9 can be used to pull the overall equipment, which is more convenient to use;

[0033] Further, the base 1 is also provided with a storage cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com