Man-machine collaboration robot grabbing system and work method thereof

A technology of human-machine collaboration and working methods, applied in the field of robotics, can solve the problems of high professional requirements and waste of time for operators, and achieve the effect of reducing professional skill requirements and smooth and compliant trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

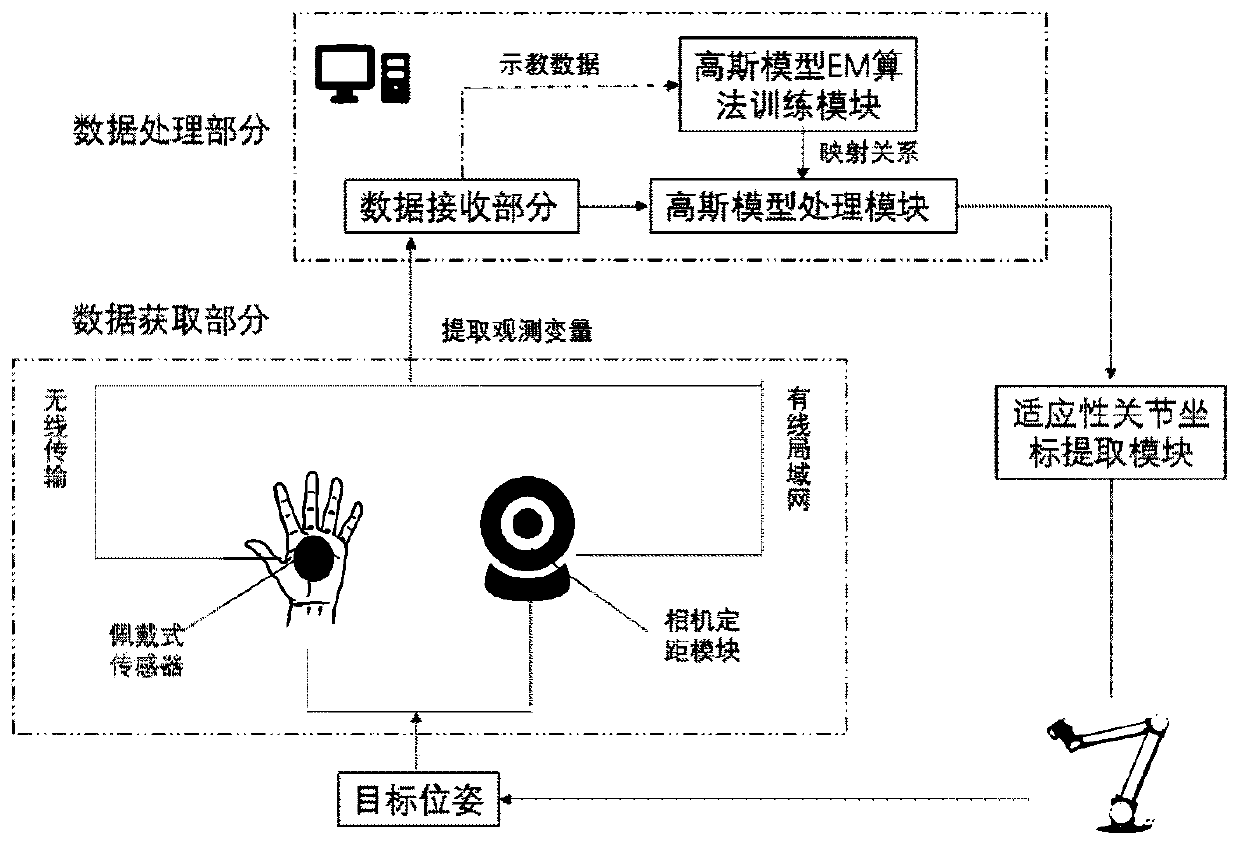

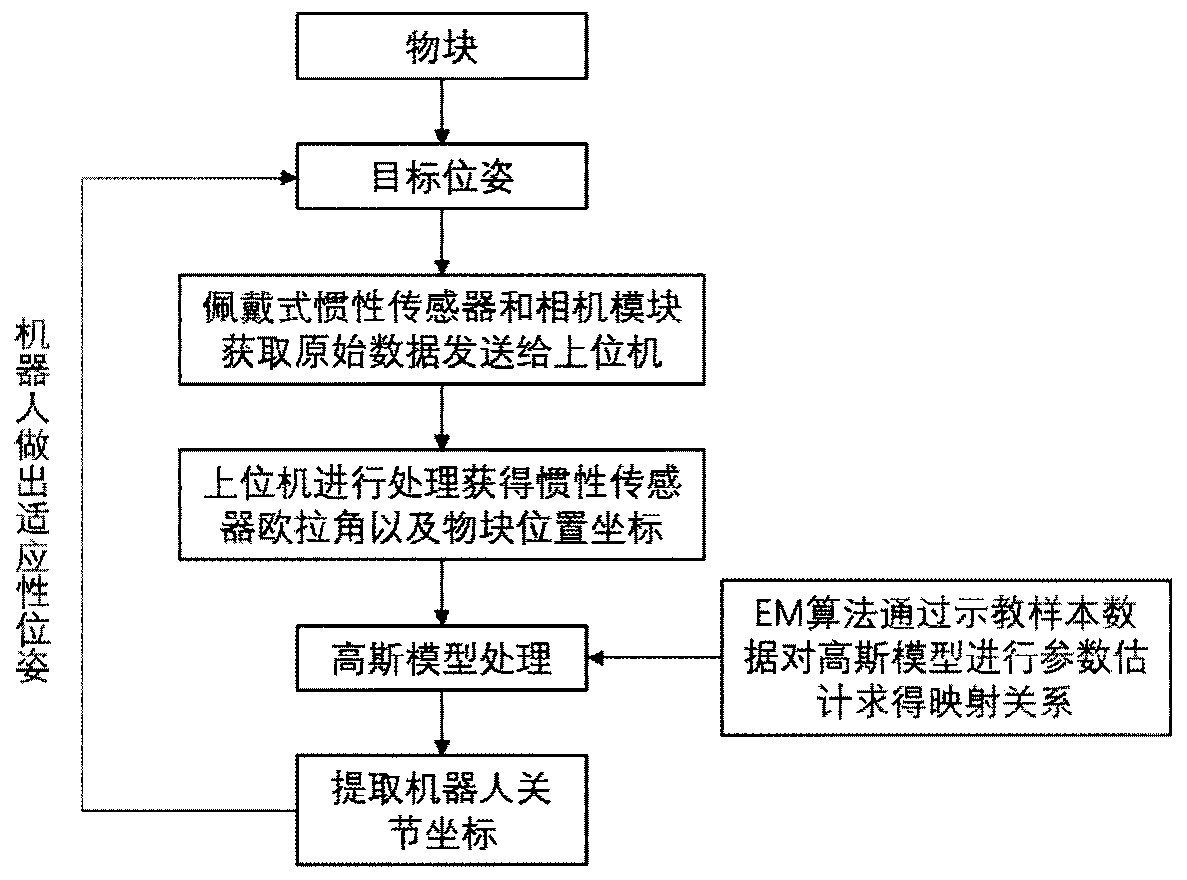

[0052] figure 1 It is a schematic structural diagram of a human-machine collaborative robot grasping system provided in Embodiment 1 of the present invention. Such as figure 1 As shown, the human-machine collaborative robot grasping system provided in this embodiment includes a wearable inertial sensor module, a camera distance determination module, a Gaussian model EM algorithm training module, a Gaussian model processing module, an adaptive robot joint coordinate extraction module, and a wearable inertial sensor module. The sensor module extracts the attitude variable of the operator grabbing the object, the camera distance module extracts the coordinates of the edge points of the object, and obtains the average value of the coordinates as the coordinates (x, y) of the center point of the target object. The Gaussian model EM algorithm training module uses the teaching data Estimate the parameters of the Gaussian model to form the mapping relationship between the object obse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com