app-Hierarchical Molecular Sieve Composite Flame Retardant and Its Preparation Method and Application

A composite flame retardant, 1.APP- technology, applied in the field of halogen-free flame retardants, can solve problems such as increasing the difficulty of fire rescue, threats to people's lives and property safety, incomplete combustion of wood, etc., and achieve good flame retardancy and Toxic attenuation performance, good adsorption of toxic gases, and the effect of reducing heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0025] Example 1-3 APP-hierarchical molecular sieve composite flame retardant and its preparation

[0026] The formulation of APP-hierarchical molecular sieve composite flame retardant is as follows:

[0027] Hierarchical 4A Molecular Sieve (g) 85% phosphoric acid aqueous solution (g) Urea (g) Example 1 3 81.19 40.14 Example 2 4 81.19 40.14 Example 3 5 81.19 40.14

[0028] The preparation method of the composite flame retardant described in Example 1 is as follows: 3 g of hierarchically porous 4A molecular sieves are placed in 81.19 g of 85% phosphoric acid aqueous solution, and dispersed for 30 min with a high-speed shear homogenizer (rotating speed 10,000 rpm) until the dispersion is uniform and no Agglomerated particles appear. Add the mixture of phosphoric acid and hierarchical pore molecular sieve into a three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, start stirring and heat at the same time, th...

Embodiment 4

[0030] The performance test of embodiment 4 flame retardant

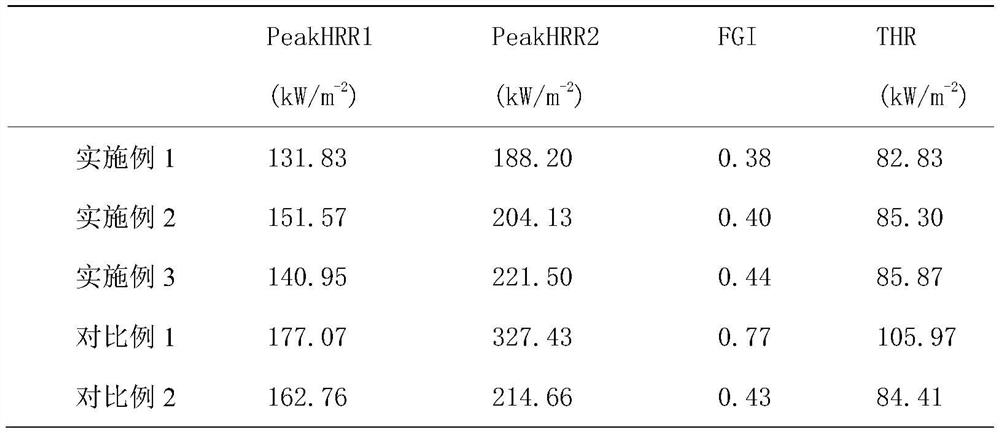

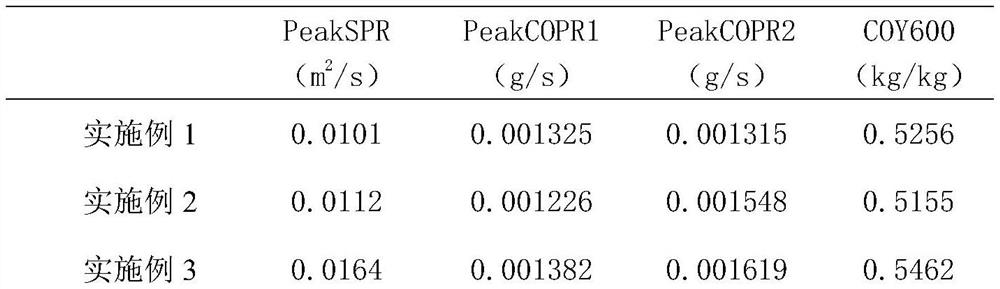

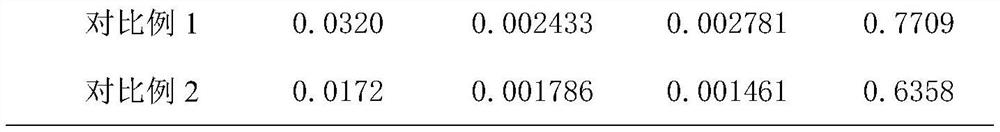

[0031] Mix the composite flame retardant prepared in Examples 1-3 and the ordinary APP flame retardant of Comparative Example 1 with wood flour, and add phenolic adhesive. The amount of flame retardant added is 10% of the mass of wood flour. The amount of adhesive added is 10% of the mass of wood flour. After mixing evenly, place it in a mold to press the flame-retardant particle board. The hot-pressing temperature is 150° C., the pressure is 1.8-2.5 MPa, and the hot-pressing time is 10 minutes to obtain a composite wood-based board. Performance testing of composite wood-based panels.

[0032] Wherein, the preparation of the ordinary APP flame retardant of Comparative Example 1 is as follows: add 81.19g of 85% phosphoric acid aqueous solution into a three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, start stirring and heat at the same time, and the heating rate is 2-3°C / min; when th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com