Automatic recycling and classifying device for beverage bottles and cans

A technology of automatic recycling and sorting device, applied in garbage collection, household appliances, applications, etc., can solve the problems of unsuitable batch beverage bottle recycling processing, low beverage bottle sorting processing efficiency, and high labor cost, so as to improve the classification The effect of recycling quality, reducing labor cost and improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

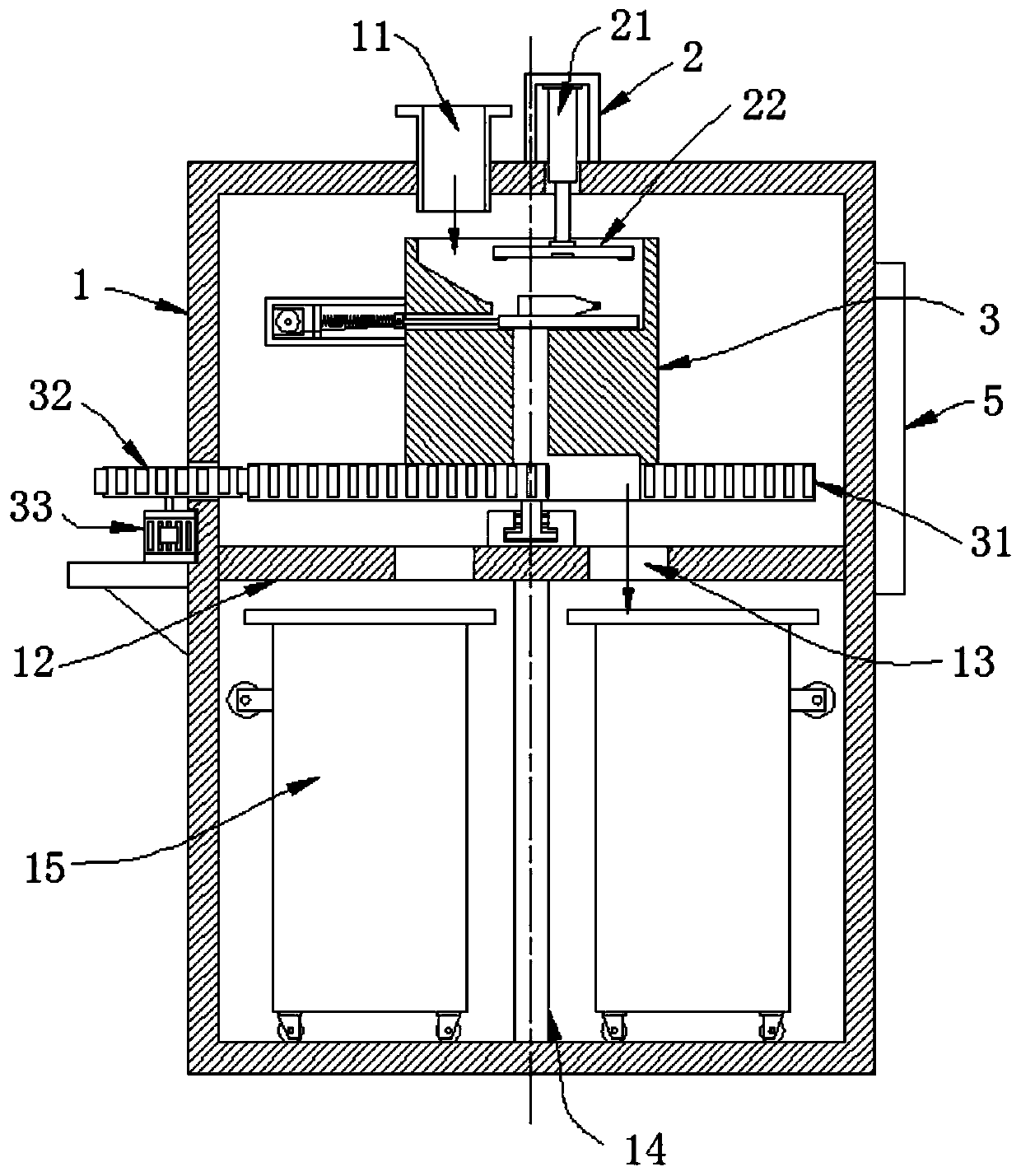

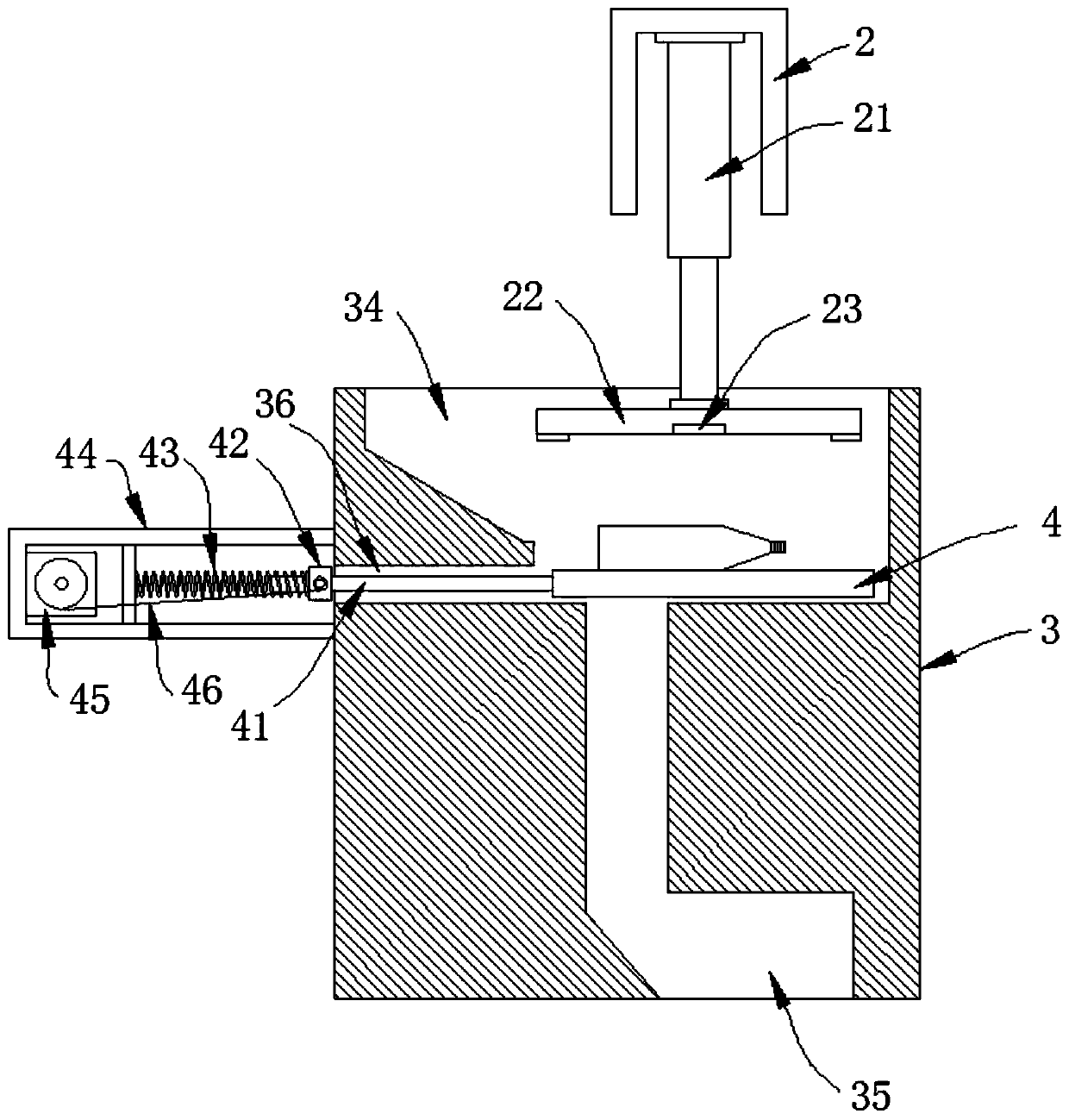

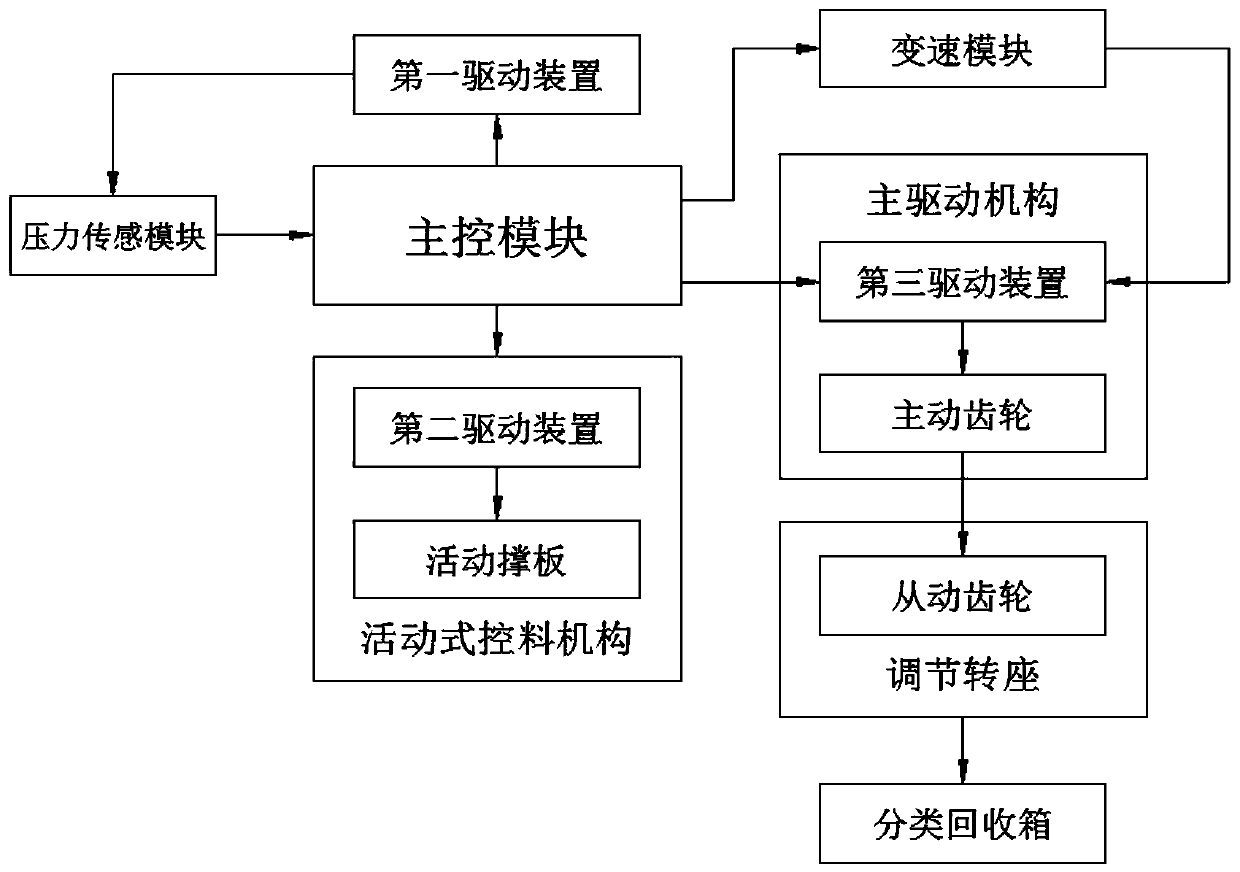

[0024] refer to Figure 1-3 , an automatic recycling and sorting device for beverage bottles and cans, including a device body 1 and an adjusting swivel seat 3 arranged inside the device body 1, and a rapid compression device for squeezing beverage bottles and cans is arranged above the adjusting swivel seat 3 mechanism, the inside of the adjusting swivel seat 3 is equipped with a movable material control mechanism, and one side of the adjusting swivel seat 3 is provided with a main drive mechanism that drives the adjusting swivel seat 3 to perform circular motion at a constant speed. The adjustable swivel seat 3 cooperates with the movable material control mechanism to complete the extrusion molding, and after forming, it is automatically sorted and recycled by the pressure of the beverage bottle and the action of the main driving mechanism.

[0025] In this embodiment, it is worth noting that the quick compression mechanism includes a fixed bracket 2 fixed on the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com