Shield tail seal grease suitable for high-temperature and low-temperature environments and preparation method thereof

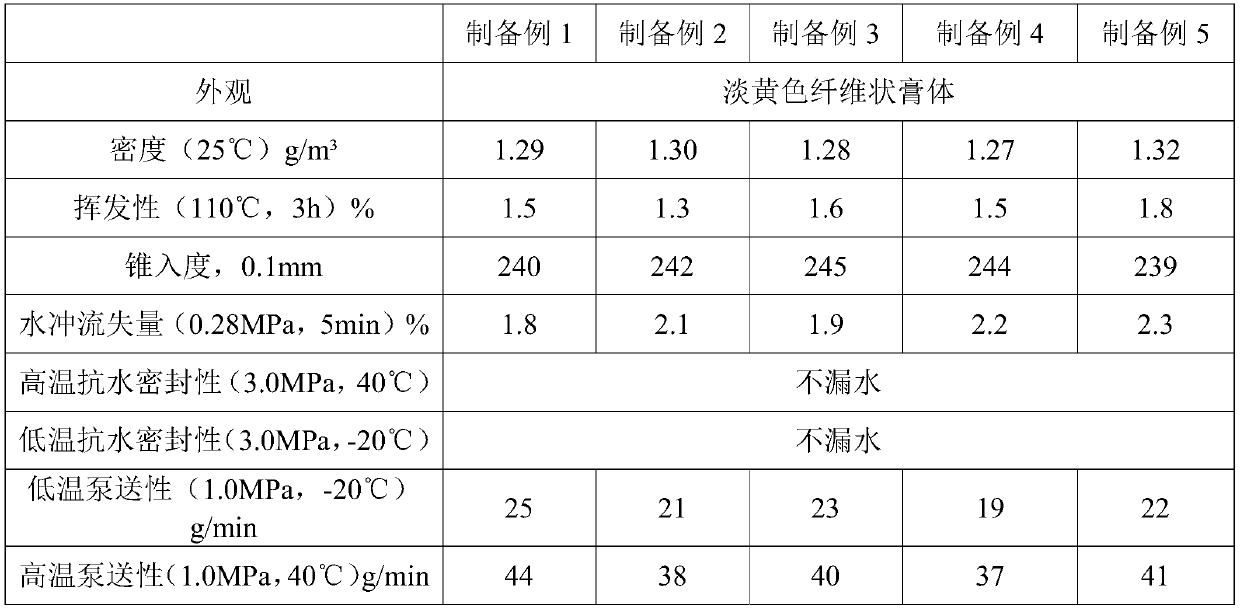

A low-temperature environment, shield tail sealing technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of shield tail seal grease thinning, poor water resistance and pressure-holding performance, shield tail seal grease hardening, etc., to achieve enhanced Adhesiveness, good water-resistance sealability, enhanced stability effect

Active Publication Date: 2019-05-10

湖北坤能科技有限公司

View PDF9 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The technical problem to be solved is: the existing shield tail sealing grease is greatly affected by temperature, the shield tail sealing grease will harden at low temperature, and the pumpability will become poor, and the shield tail sealing grease will become thinner at hig

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

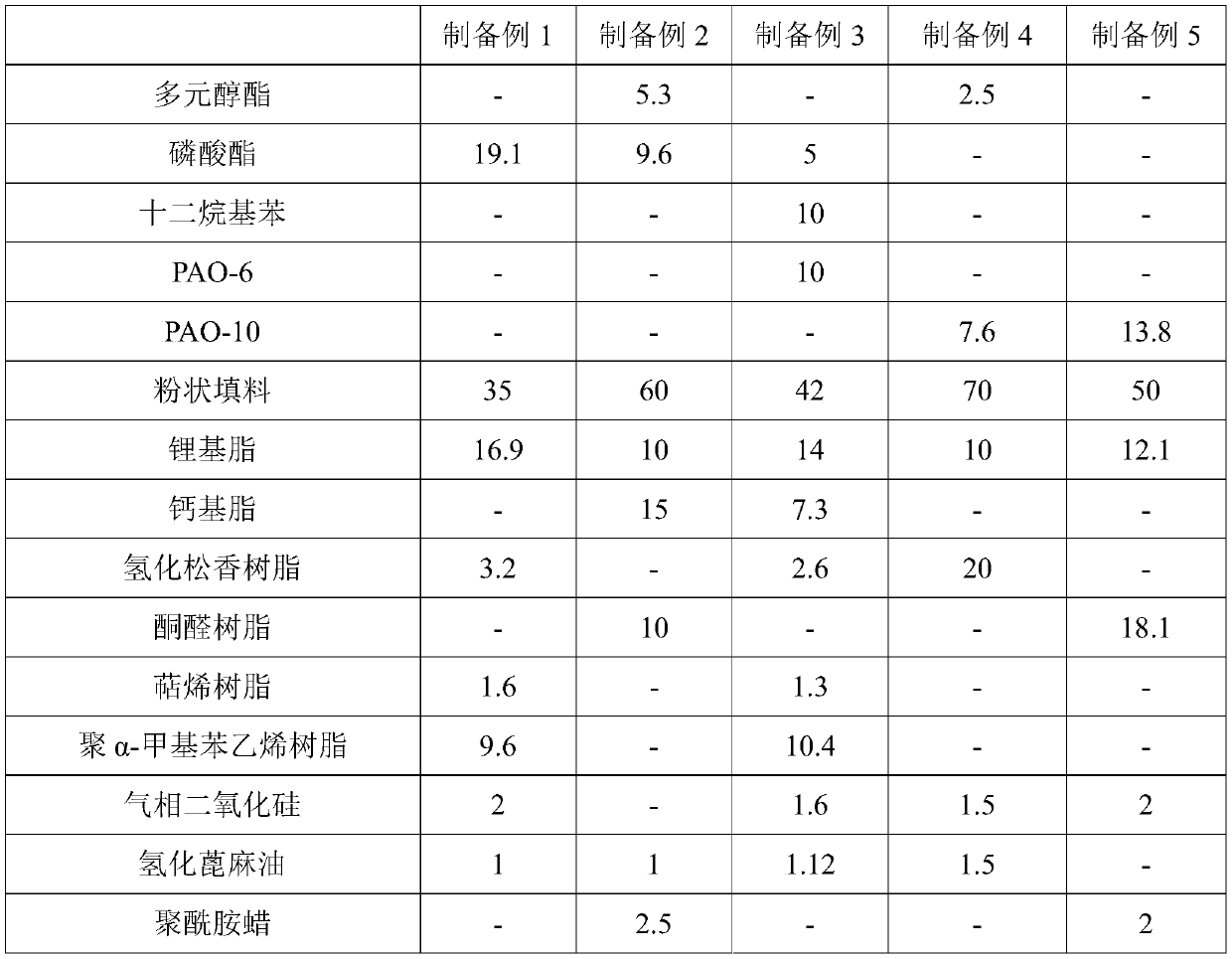

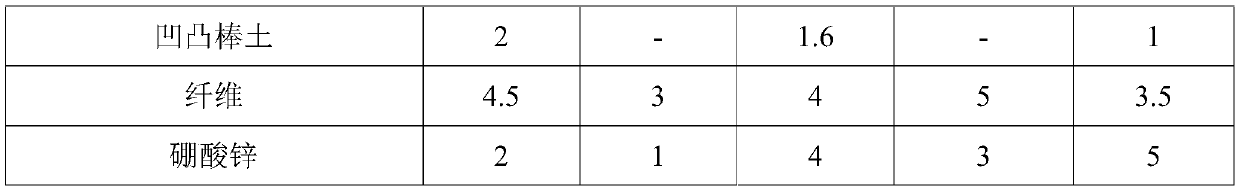

The invention relates to the technical field of shield tail seal grease, and discloses shield tail seal grease suitable for high-temperature and low-temperature environments and a preparation method thereof. The shield tail seal grease comprises the following ingredients in parts by weight: 35-70 parts of powdery filler, 10-25 parts of base oil, 10-25 parts of a thickening agent, 10-20 parts of atackifier, 3-5 parts of fiber, 1-5 parts of a fire retardant and 3-5 parts of a thixotropic agent. According to the shield tail seal grease, the ingredients are simple, the cost is low, the preparation is easy, and the sealing performance is good.

Description

technical field [0001] The invention relates to the technical field of shield tail sealing grease, in particular to a shield tail sealing grease suitable for high temperature and low temperature environments and a preparation method thereof. Background technique [0002] In recent years, the number of tunnel projects has gradually increased. In order to meet people's needs, more and more large-depth tunnel projects have been constructed. The key factor of the whole tunnel construction quality, therefore, tunnel engineering construction must pay attention to shield tail waterproof sealing construction. [0003] Shield construction is the main method of urban rail transit tunnel construction. Shield tail sealing grease is the main material for sealing and waterproofing in shield construction. During the tunneling process of the shield machine, there is a gap between the shield shell and the outer wall of the segment. When water and sediment outside the shield shell enter the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M169/00C10N30/08C10N40/34

Inventor 魏清宝许亮孙艳徐鹏舒海高心星蔡珩

Owner 湖北坤能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com