Tailrace tunnel bent pipe section steel mould trolley concrete lining construction method

A technology of steel formwork trolley and construction method, which is applied in the direction of infrastructure engineering, construction, etc., can solve the problems of long construction period, large one-time input of turnover materials, safety risks, difficulty in controlling the appearance quality of concrete, etc., and achieves short construction period and good quality. Economic and quality benefits, convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments.

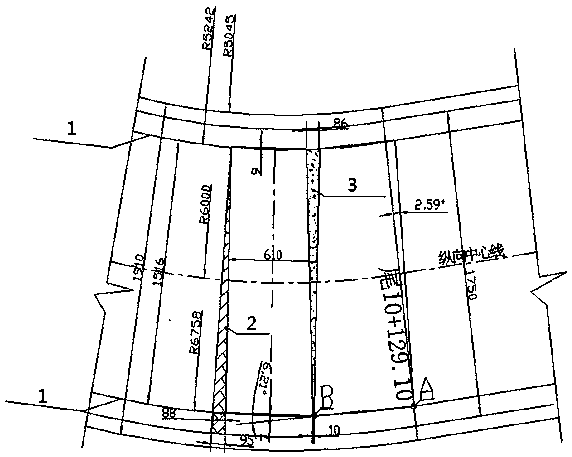

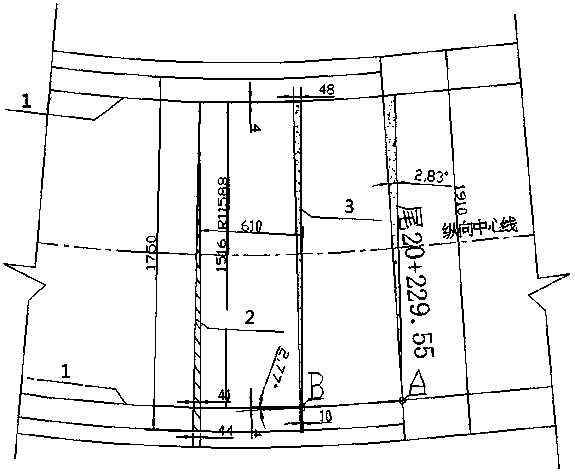

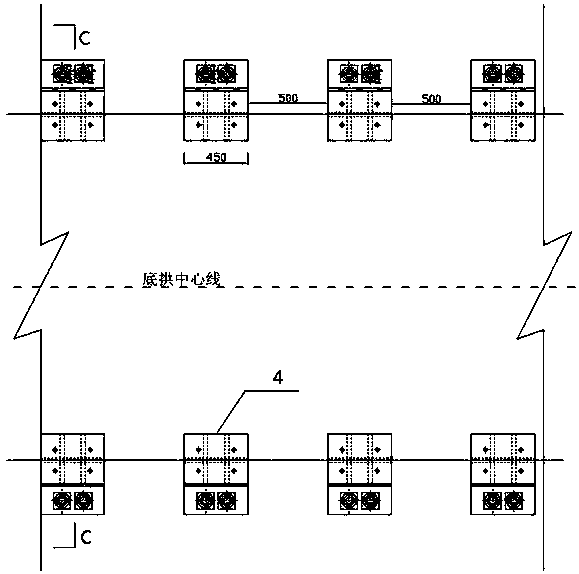

[0023] A construction method for concrete lining of steel mold trolley in the elbow section of tailwater tunnel, such as Figure 1-6 As shown, the construction method includes:

[0024] (1) Reconstruction measures for trolley running track: During the lining process of the tailrace tunnel, since the steel bar installation trolley and the steel mold lining trolley are both designed as straight lines, when entering the turning section, arc must be performed on the track it travels. line arrangement. Since the purchased rails are all straight heavy rails, the construction unit has no condition to purchase a bending machine for bending design, so it is necessary to bend the straight rails at the construction site. The measures are as follows: firstly carry out measurement and stakeout, and the survey team will carry out track sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com