A connection structure and manufacturing method of prefabricated exterior wall horizontal strips

A technology of prefabricated wall panels and production methods, which are applied to building structures, walls, building components, etc., can solve problems such as poor stress state, potential safety hazards, and short distance between top and bottom connection points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

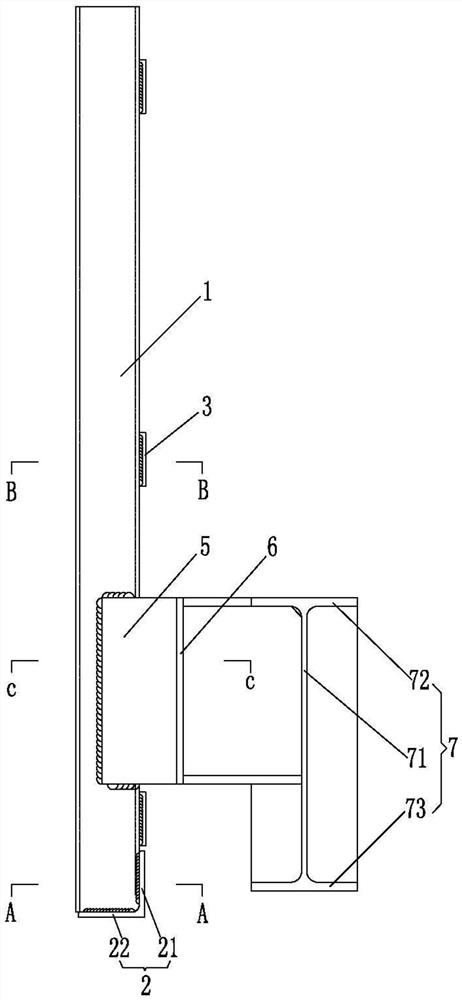

[0022] Please refer to the attached figure 1 to attach Figure 4 As shown, the present invention is a connection structure of prefabricated exterior wall horizontal strips, which consists of cantilever columns 1, supporting plates 2, wind-resistant tie lugs 3, prefabricated wall panels 4, adapter plates 5, and structural secondary beams 6 And several parts such as structural frame beam 7 are assembled.

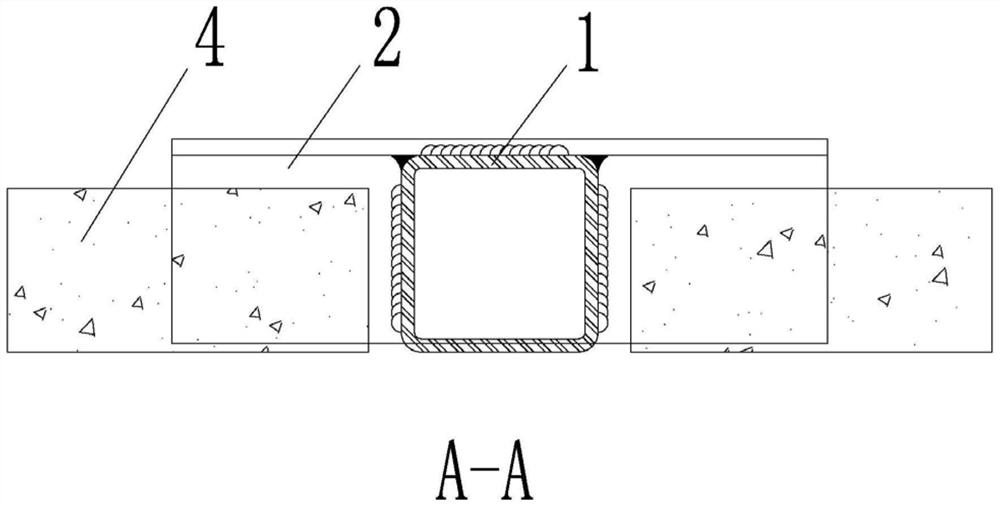

[0023] Wherein, the cantilever column 1 is arranged vertically and is made of a rectangular square tube.

[0024] The supporting plate 2 is welded to the bottom of the cantilever column 1 and is integrally formed by a vertical plate 21 and a horizontal plate 22 . The vertical plate 21 is welded to the cantilever column 1; the horizontal plate 22 is arranged horizontally and located on both sides of the bottom of the cantilever column 1.

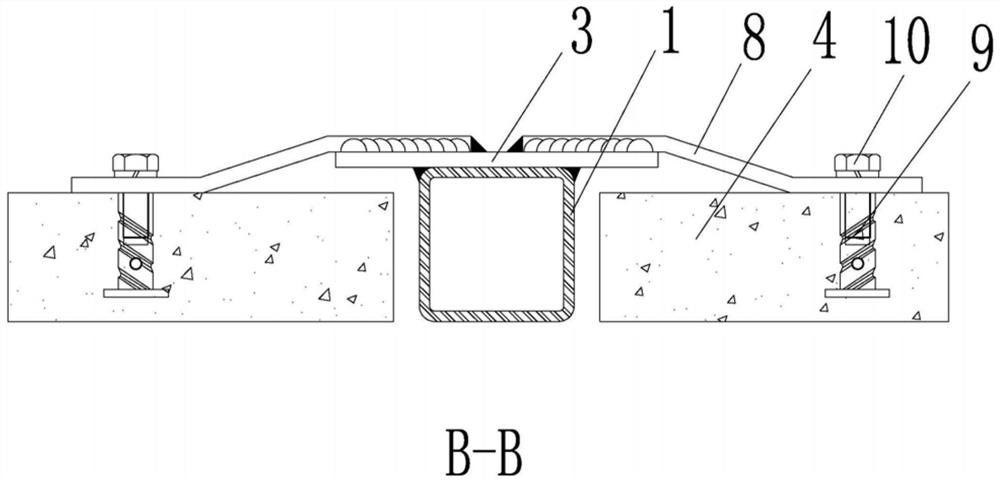

[0025] The wind-resistant tie lug 3 is welded on the cantilever column 1 . A tie plate 8 is welded on the wind-resistant tie lug 3 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com