Prefabricated laminated slab and prefabrication process thereof

A technology of laminated slabs and crafts, applied in floors, building components, buildings, etc., can solve problems such as cracking of the pouring layer, weak adhesion, and offset of laminated slabs, so as to improve adhesion, reduce processing steps, and improve structure intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

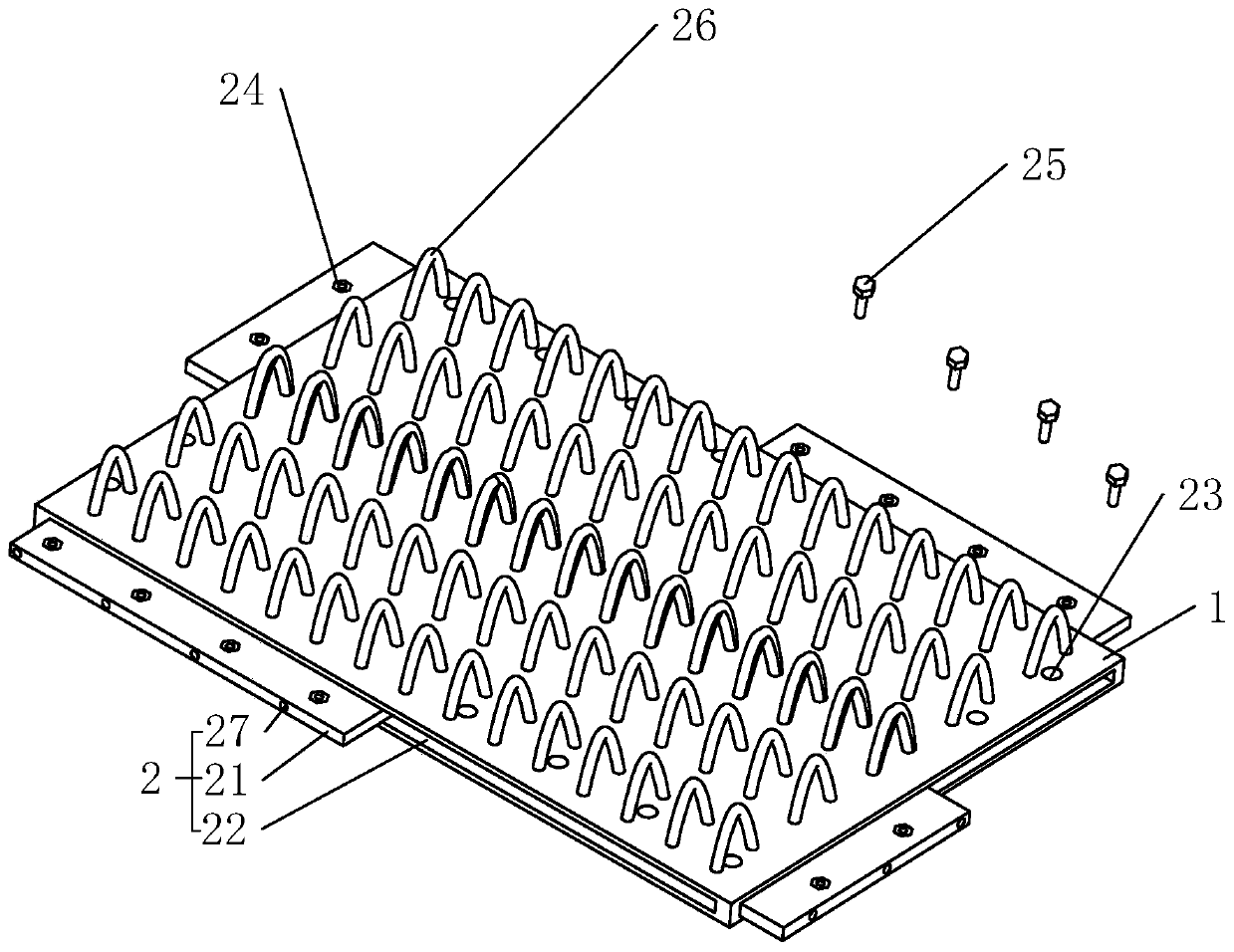

[0040] Such as figure 1 As shown, a prefabricated laminated board includes a board body 1 and a connecting structure 2. The board body 1 is formed by pouring concrete and is in the shape of a rectangular board. A steel frame 3 is pre-embedded inside the board body 1 .

[0041] The connection structure 2 includes a fitting block 21, a fitting groove 22, a connecting hole 23, a connecting block 24, a connecting piece 25, a connecting ring 26, and a rib hole 27. The fitting block 21 is integrally formed on the board body 1, and on the board Fitting blocks 21 are provided on the four side walls of the body 1; the number of fitting grooves 22 is equal to that of the fitting blocks 21, which are integrally formed on the board body 1 and are located on the same side wall of the board body 1 21 and the fitting groove 22 are adjacent to each other; the fitting block 21 and the fitting groove 22 are paired, and are used for forming an insertion fit between two adjacent boards 1 when the...

Embodiment 2

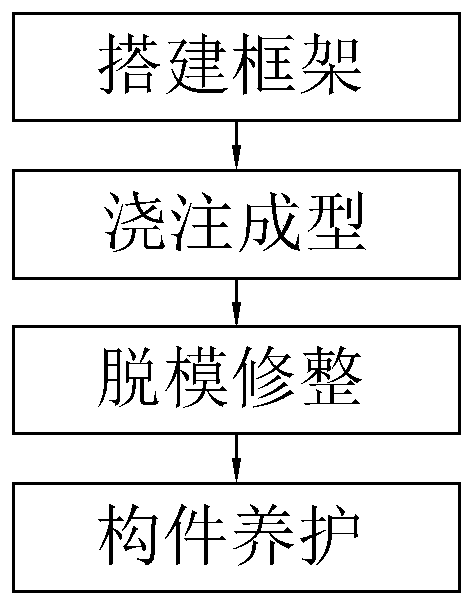

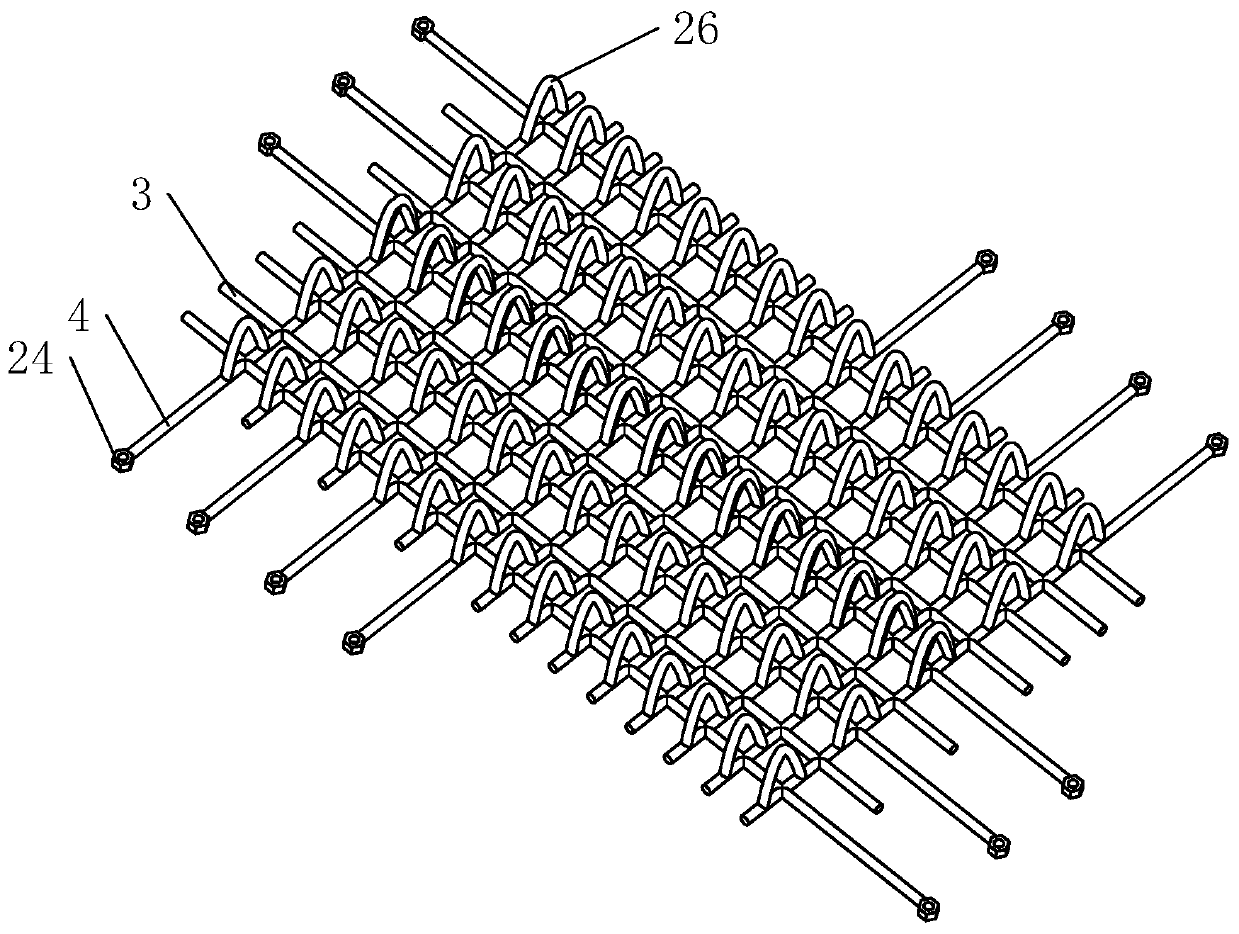

[0047] Such as figure 2 and image 3 Shown, a kind of prefabrication technology of prefabricated laminated board comprises the following steps:

[0048] (1) Build the frame, lay the steel bars crosswise in the shape of "well", and then use steel wires to bind and position the intersections of two adjacent steel bars, and then weld and reinforce the intersections between the steel bars. At this time, the laminated plate The steel frame is initially formed.

[0049] One thing to note is that in the process of building the frame, a part of the steel bars should be exposed on the side of the frame as the supporting part required to form the fitting block, and then the nuts need to be welded at the end of the supporting part, and the A block of wax is melted in the center of the nut, and the thickness of the wax block is greater than the thickness of the laminated slab when it is finally formed, so that after the steel frame is placed in the mold and concrete is poured, the nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com