A high temperature molten salt pipeline valve

A pipeline valve, high temperature molten salt technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of graphite packing gasification, stuffing box leakage, etc., to improve sealing, good practicability and adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

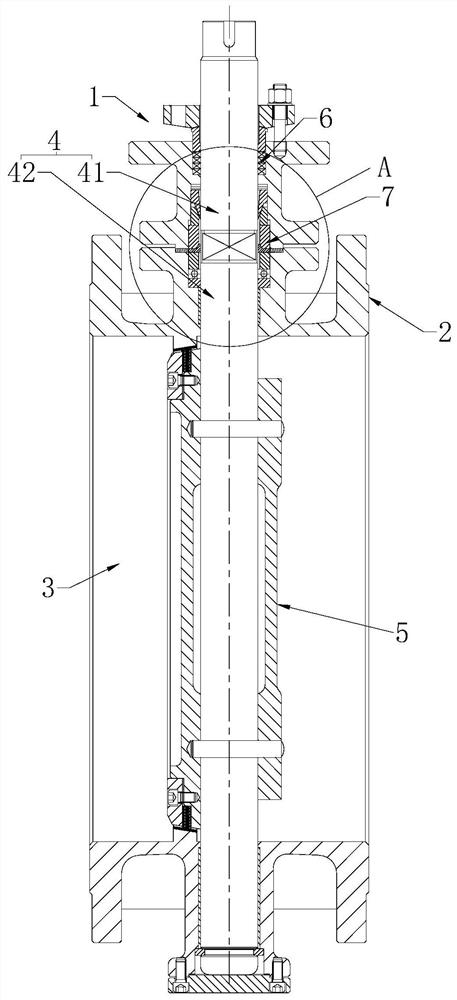

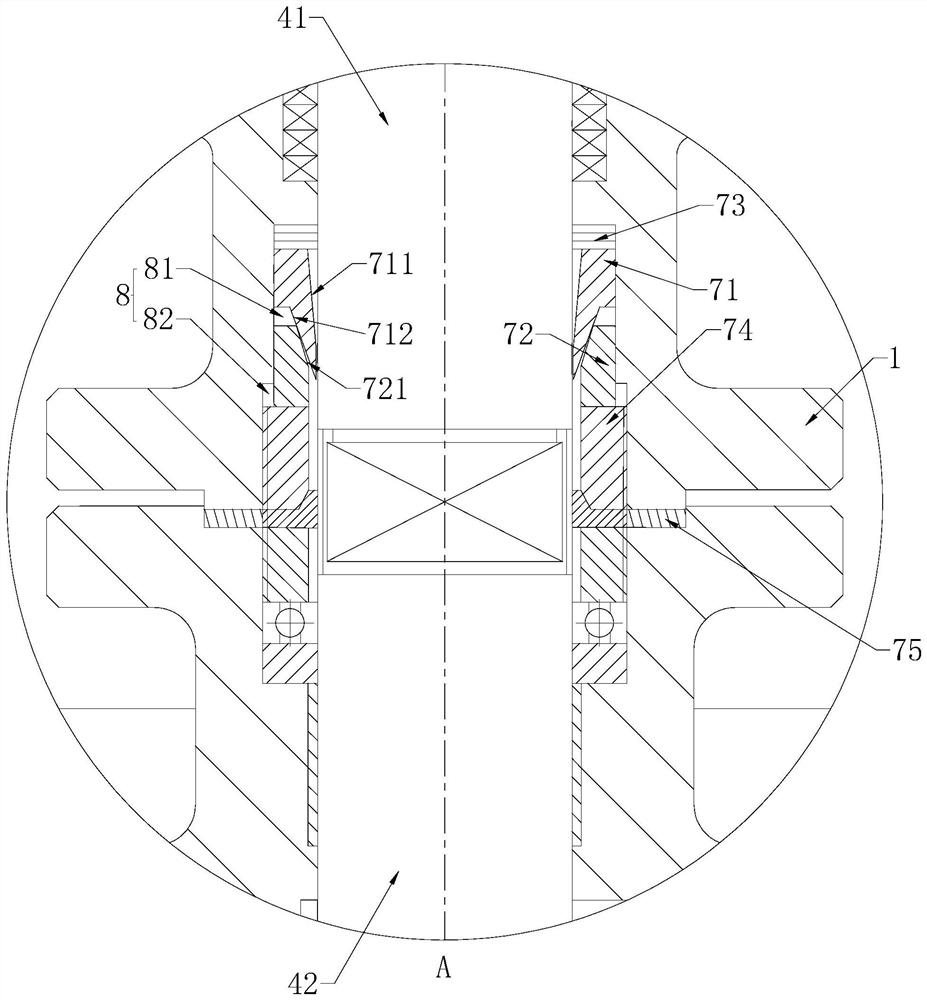

[0037] to combine figure 1 and figure 2 As shown, a high-temperature molten salt pipeline valve includes a bracket 1 and a valve body 2 installed on the bracket 1, and a chamber 3 is formed in the valve body 2, and a valve is installed vertically in the bracket 1 and the valve body 2. The stem 4 is connected with the valve core 5 protruding into the chamber 3 . In the process of using the valve, the high-temperature liquid-phase molten salt medium will exert a thrust on the valve stem 4 along the direction of medium flow, and a small gap will be formed between the valve stem 4 and the bracket 1 under the action of the thrust; while the high-temperature liquid-phase molten salt The salt medium can enter the stuffing box 6 along the tiny gap between the valve stem 4 and the bracket 1, contact with the graphite packing in the stuffing box 6 and vaporize the graphite packing, causing the stuffing box 6 to leak. Therefore, in the present invention, the valve stem 4 is set as a m...

Embodiment 2

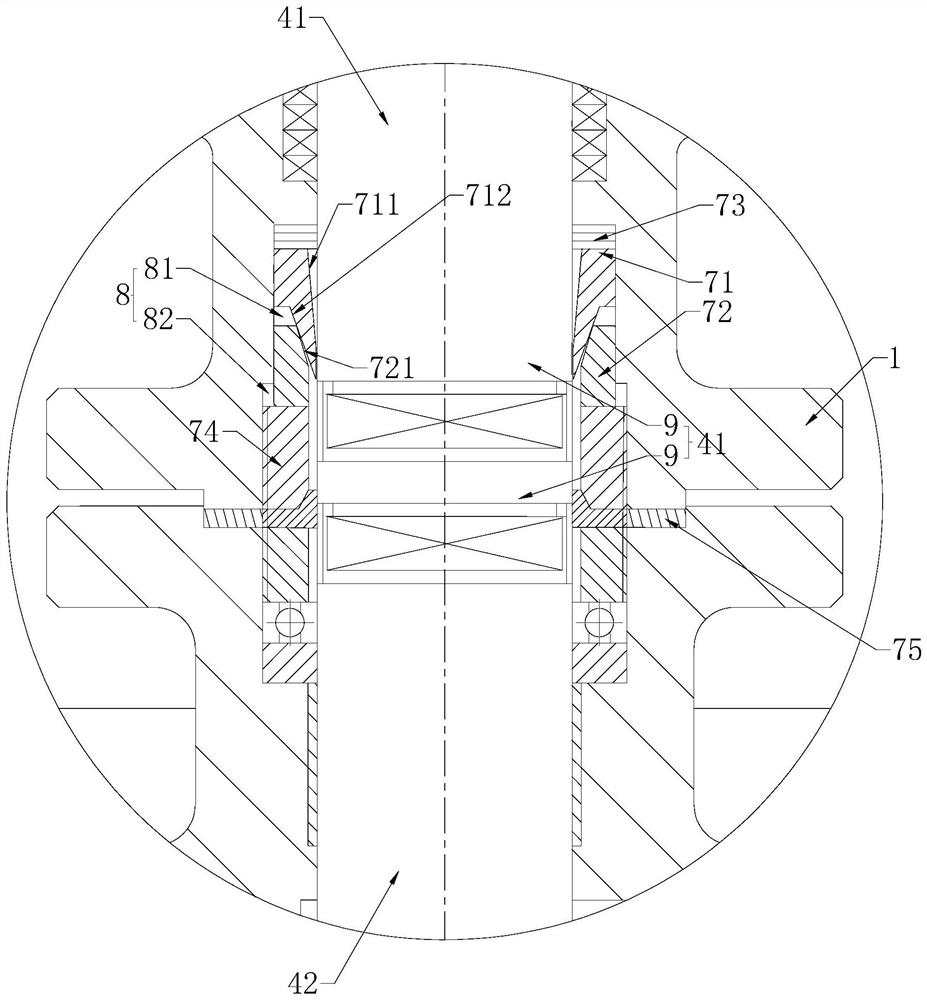

[0050] to combine figure 1 and image 3 As shown, a high-temperature molten salt pipeline valve differs from Embodiment 1 in that the upper valve stem 41 is configured as a multi-segment rod structure (in this embodiment, it is a two-segment upper valve stem 41). The upper valve stem 41 includes a plurality of connecting valve stems 9 that are snap fit and realize transmission (the joint connecting the valve stem 9 is located between the sliding bearing and the mechanical seal structure 7), and two adjacent valve stems after snap fit There is a transmission weakening gap formed between the connecting valve stems 9; when the radial thrust acting on the valve core 5 is relatively large, the thrust is transmitted to the connection along the lower valve stem 42 and weakened by the thrust weakening gap, there is still a small amount of thrust Acting on the connecting valve rod 9 connected with the lower valve rod 42, a small amount of thrust is further weakened through the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com