A system for the treatment of process water in integrated trench sludge treatment station

A technology for communicating sludge and treatment systems, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of improving and adjusting the size of sewage circulation gaps, unfavorable sloping plate sedimentation tank efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

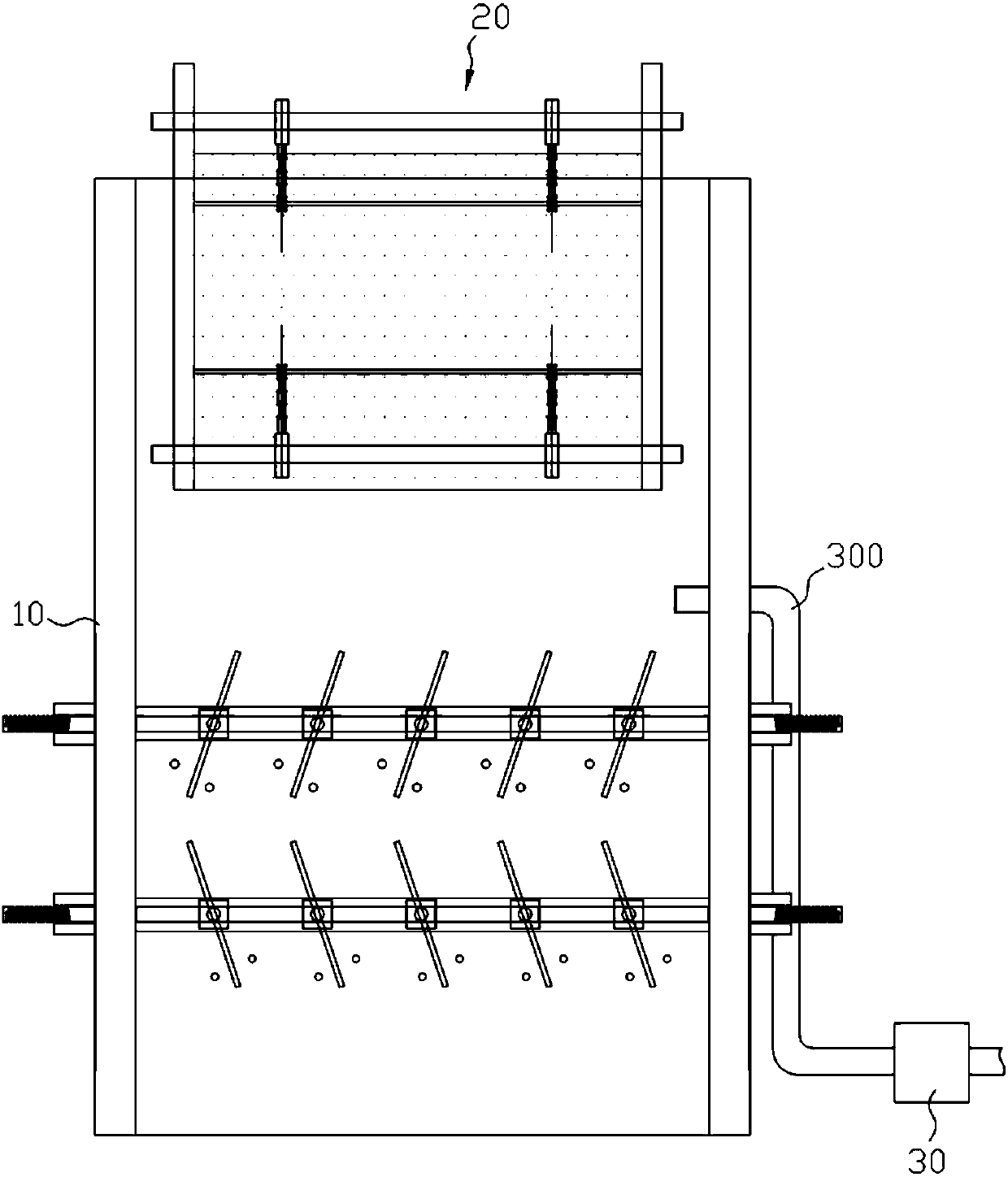

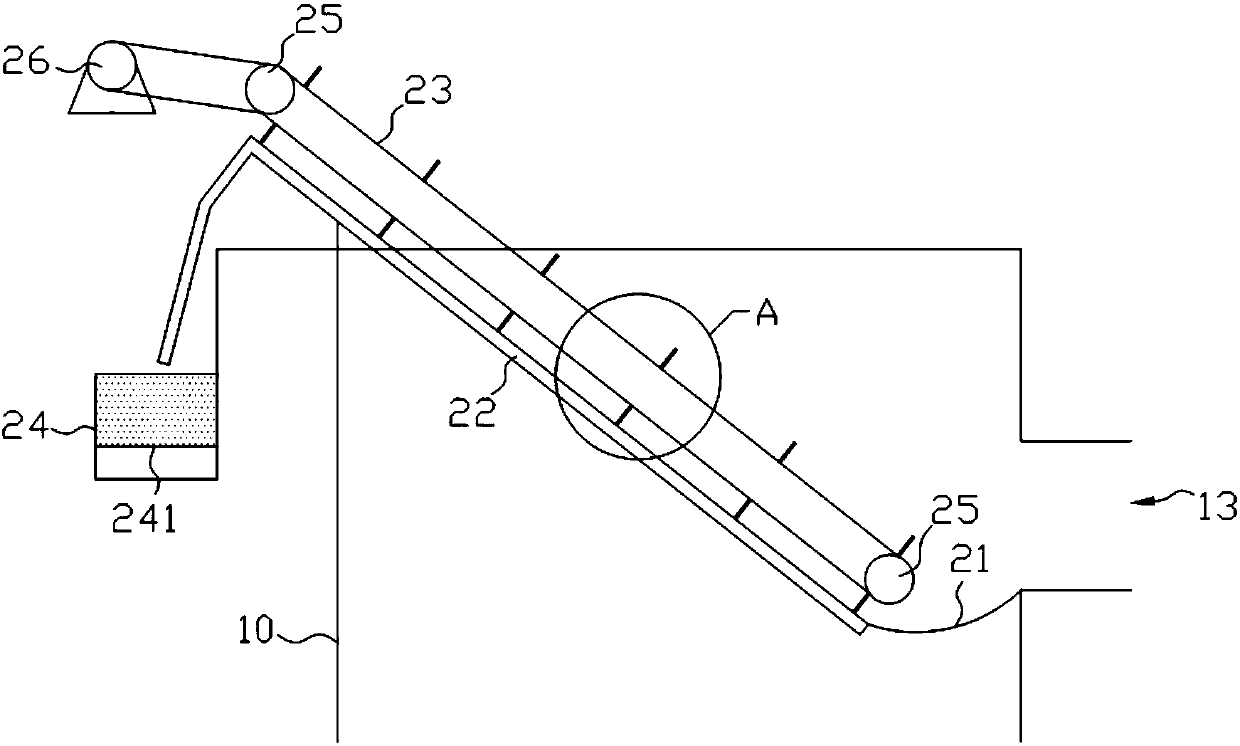

[0032] combine figure 1 , Figure 4 , Figure 5 , a treatment system for the process water of a ditch sludge integrated treatment station, comprising a sloping plate sedimentation tank 10, a fully automatic filter 20 located above the sloping plate sedimentation tank, and a water pump 30 arranged outside the sloping plate sedimentation tank; The water pump is connected with a water suction pipe 300, one end of the water suction pipe is connected with the water pump, and the other end of the water suction pipe is arranged below the fully automatic filter and above a row of inclined plates 40 in the inclined plate sedimentation tank.

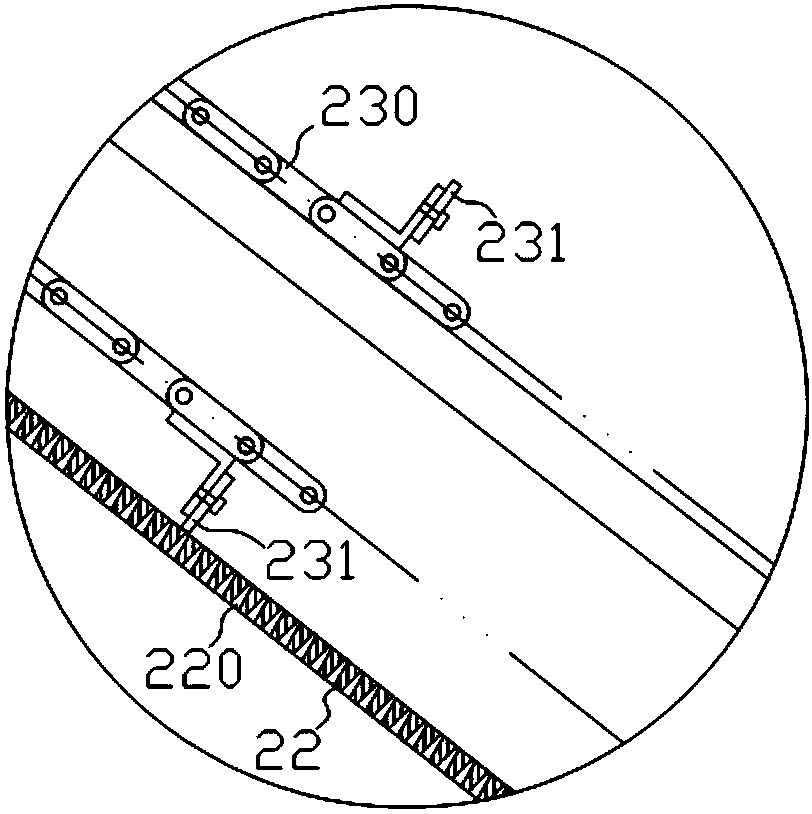

[0033] to combine Figure 4 , Figure 5 , the row of inclined plates is arranged longitudinally in the inclined plate sedimentation tank, and the density of the inclined plates is less than that of water. Each inclined plate is horizontally arranged in the inclined plate sedimentation tank, and the two ends of each inclined plate are provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com