A measuring device and method for calibrating tooling and intermating gap of blind mating connectors

A measurement device and measurement method technology, applied in the direction of measurement devices, instruments, etc., can solve problems such as poor consistency of measurement data, and achieve the effects of simple test tooling, good consistency, and high test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

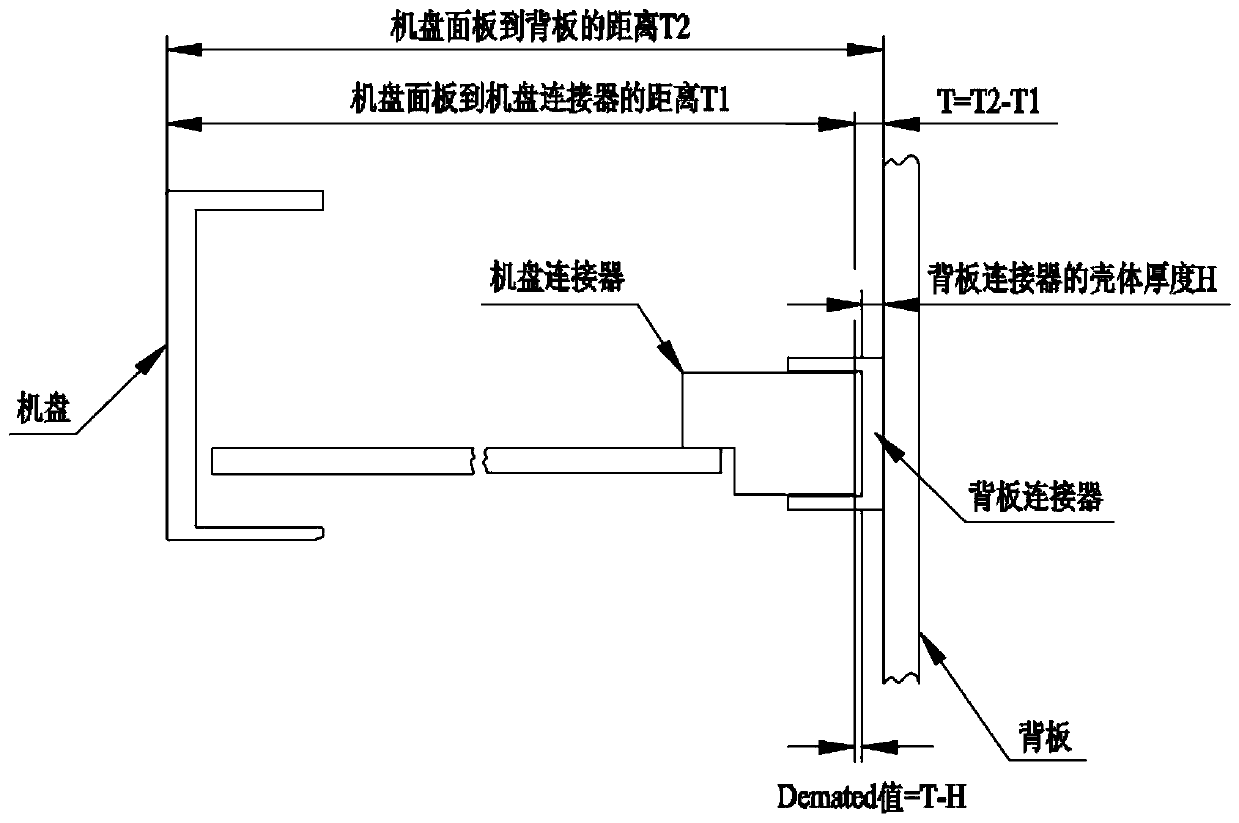

[0050] see Figure 4 to Figure 8 As shown, the embodiment of the present invention provides a measuring device for the mating gap of blind mating connectors, which includes a calibration tool 1 and a simulation board 2 .

[0051] Wherein, a groove 11 is provided on the calibration tool 1, and the depth S of the groove 11 is the part of the pin length used for docking the signal pin on the backplane connector with the chassis connector plus the thickness of the shell bottom of the backplane connector. .

[0052] Emulator Disk 2, which includes,

[0053] - disc body 21;

[0054] - a plurality of machine disk connectors, which are all fixed on the disk body 21;

[0055] - At least one displacement sensor 22, which is fixed on the disc body 21 and is arranged adjacent to one of the disc connectors, and the part of the displacement sensor 22 protruding from the disc body 21 exceeds the disc the length of the connector is slightly greater than said depth S;

[0056] - a displac...

Embodiment 2

[0064] see Figure 4 to Figure 8 As shown, the embodiment of the present invention provides a measuring device for the mating gap of blind mating connectors, which includes a calibration tool 1 and a simulation board 2 .

[0065] Wherein, a groove 11 is provided on the calibration tool 1, and the depth S of the groove 11 is the part of the pin length used for docking the signal pin on the backplane connector with the chassis connector plus the thickness of the shell bottom of the backplane connector. .

[0066] Emulator Disk 2, which includes,

[0067] - disc body 21;

[0068] - a plurality of machine disk connectors, which are all fixed on the disk body 21;

[0069] - At least one displacement sensor 22, which is fixed on the disc body 21 and is arranged adjacent to one of the disc connectors, and the part of the displacement sensor 22 protruding from the disc body 21 exceeds the disc the length of the connector is slightly greater than said depth S;

[0070] - a displac...

Embodiment 3

[0074] see Figure 4 to Figure 8 As shown, the embodiment of the present invention provides a measuring device for the mating gap of blind mating connectors, which includes a calibration tool 1 and a simulation board 2 .

[0075] Wherein, a groove 11 is provided on the calibration tool 1, and the depth S of the groove 11 is the part of the pin length used for docking the signal pin on the backplane connector with the chassis connector plus the thickness of the shell bottom of the backplane connector. .

[0076] Emulator Disk 2, which includes,

[0077] - disc body 21;

[0078] - a plurality of machine disk connectors, which are all fixed on the disk body 21;

[0079] - At least one displacement sensor 22, which is fixed on the disc body 21 and is arranged adjacent to one of the disc connectors, and the part of the displacement sensor 22 protruding from the disc body 21 exceeds the disc the length of the connector is slightly greater than said depth S;

[0080] - a displac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com