Gear fatigue testing machine considering gear misalignment and gear surface unbalanced loading

A fatigue testing machine and gear technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as limitations, difficulty in simulating the structure of gearboxes, and few gear fatigue life. The effect of load torque, high stability and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

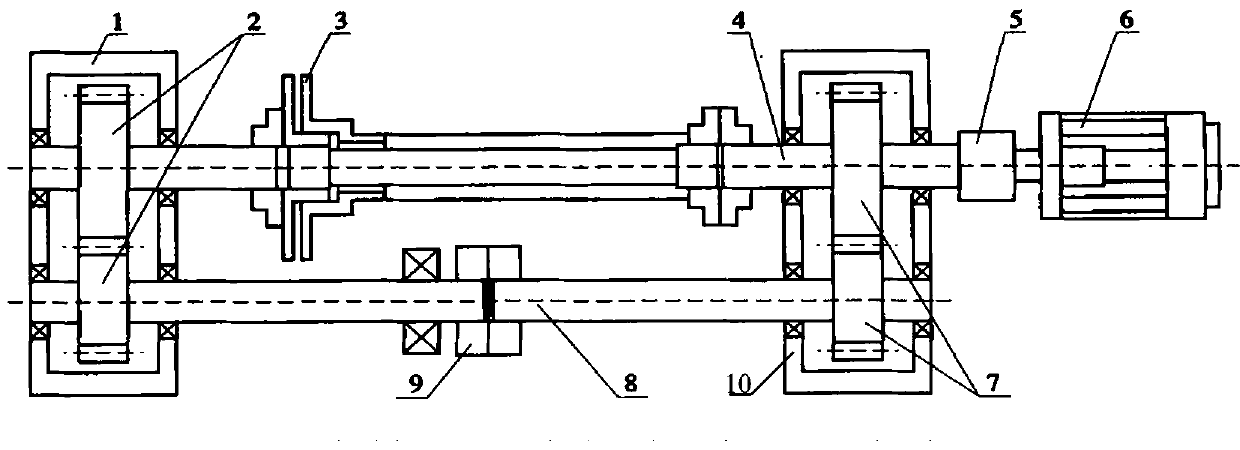

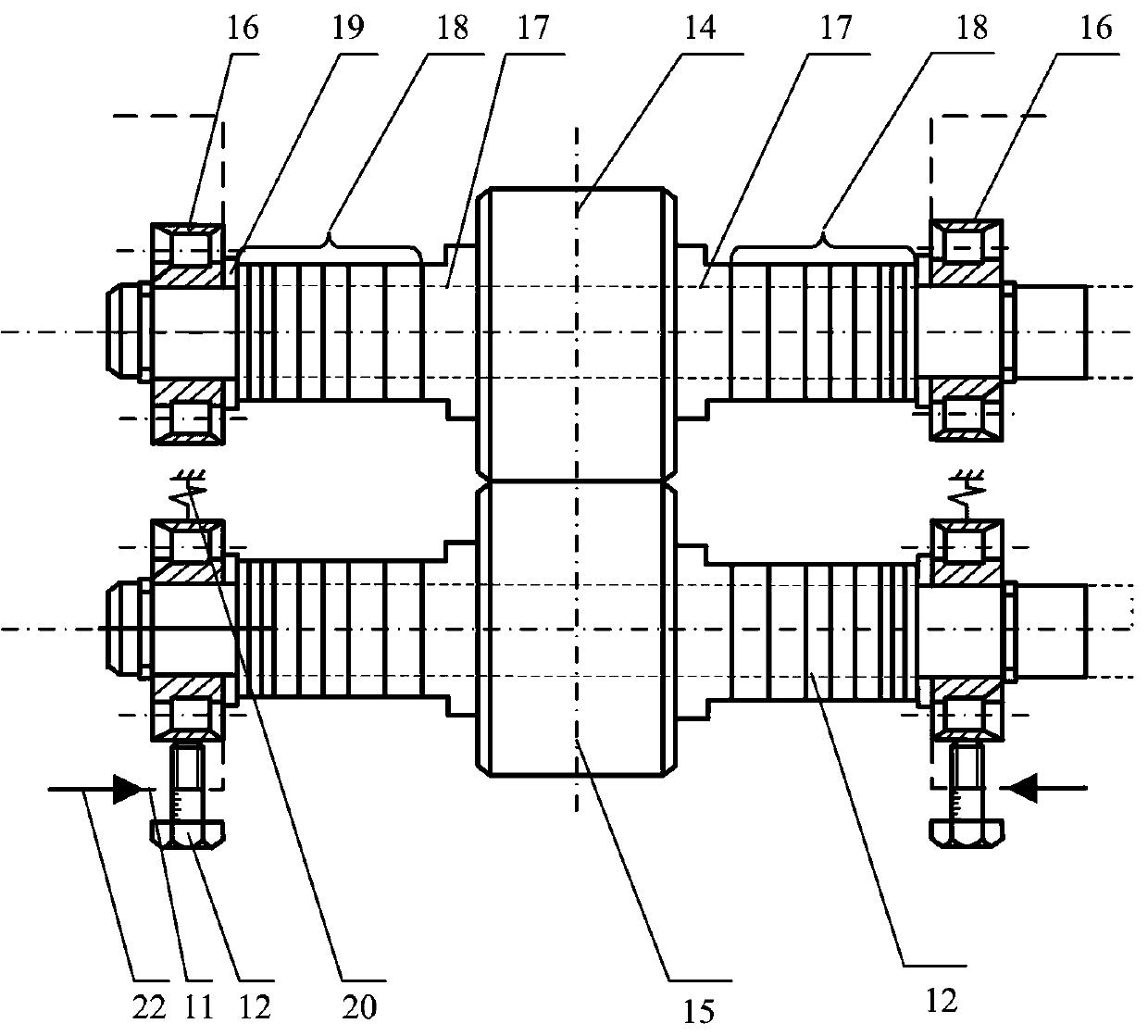

[0029] Example 1: Test gearbox control eccentric load adjustment

[0030] like Figure 4 shown, for figure 1 The test gear box control eccentric load adjustment schematic diagram; where: (a) before eccentric load adjustment; (b) after eccentric load adjustment; the specific eccentric load adjustment steps are as follows: when the eccentric load needs to be adjusted l , find the adjusting bushing 4-1 of the corresponding thickness. Before the gear is installed, the eight-tooth rectangular spline driven shaft is pulled out from the gearbox, and the adjusting bushing on the left side is moved to the position of the adjusting bushing on the right side of the shaft section. 4-3, and then complete the installation of the rest of the parts to achieve the partial load of t The eccentric load of the tooth surface is installed in 4-4.

Embodiment 2

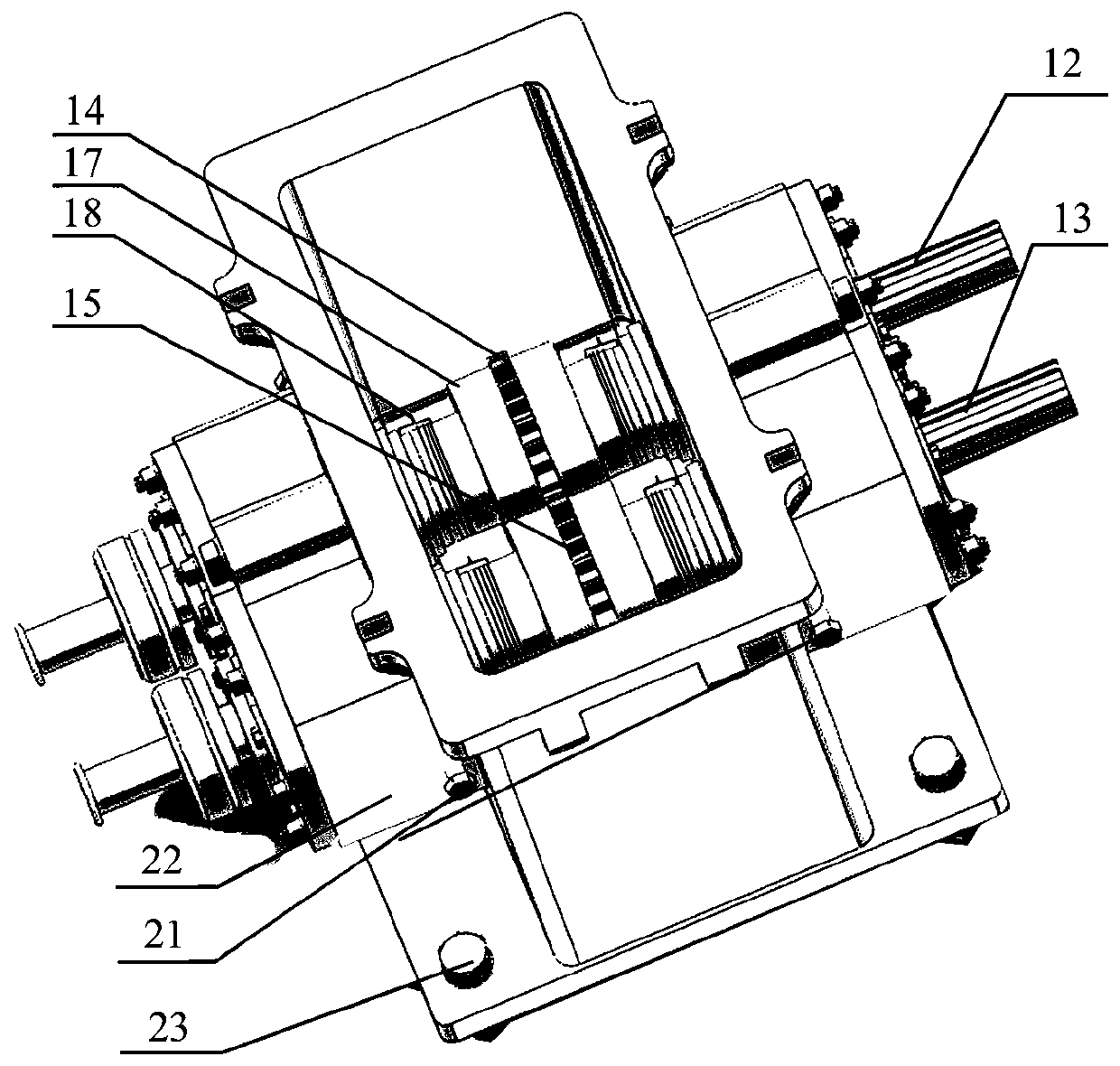

[0031] Example 2: Testing Gearbox Misalignment Adjustment

[0032] like Figure 5 shown, for figure 1 The schematic diagram of the misalignment adjustment of the tested gearbox; where: (a) standard installation schematic diagram; (b) angular misalignment adjustment schematic diagram; (c) center distance error adjustment schematic diagram; the specific angular misalignment and center distance error adjustment steps are as follows: When it is necessary to adjust the misalignment of the gear angle, adjust the distance adjusting bolt on the left side alone (or adjust the distance adjusting bolt on the right side alone, and the left side does not move), the right side bolt remains still, and the effective shaft section length supported by the bearing is n , the length of the compressed spring on the left is m (see Figure 5-1), the length is obtained by observing the indicator cursor, then the angular misalignment at this time θ as (see Figure 5-2):

[0033] (1)

[0034] Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com