Raw material sample-preparation system

A sample preparation system and raw material technology, applied in the preparation of test samples, weighing by removing certain components, etc., can solve the problems of contaminated samples, difficulty in ensuring the consistency of sample preparation results, etc., to ensure consistency and accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

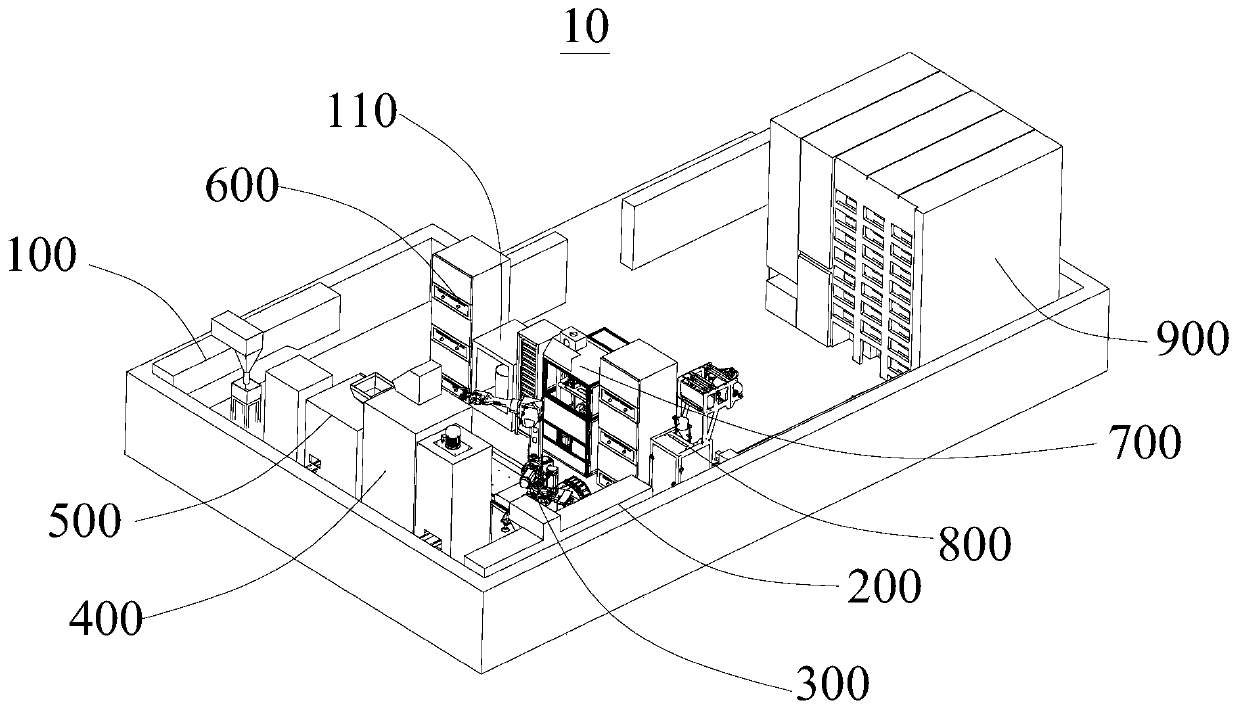

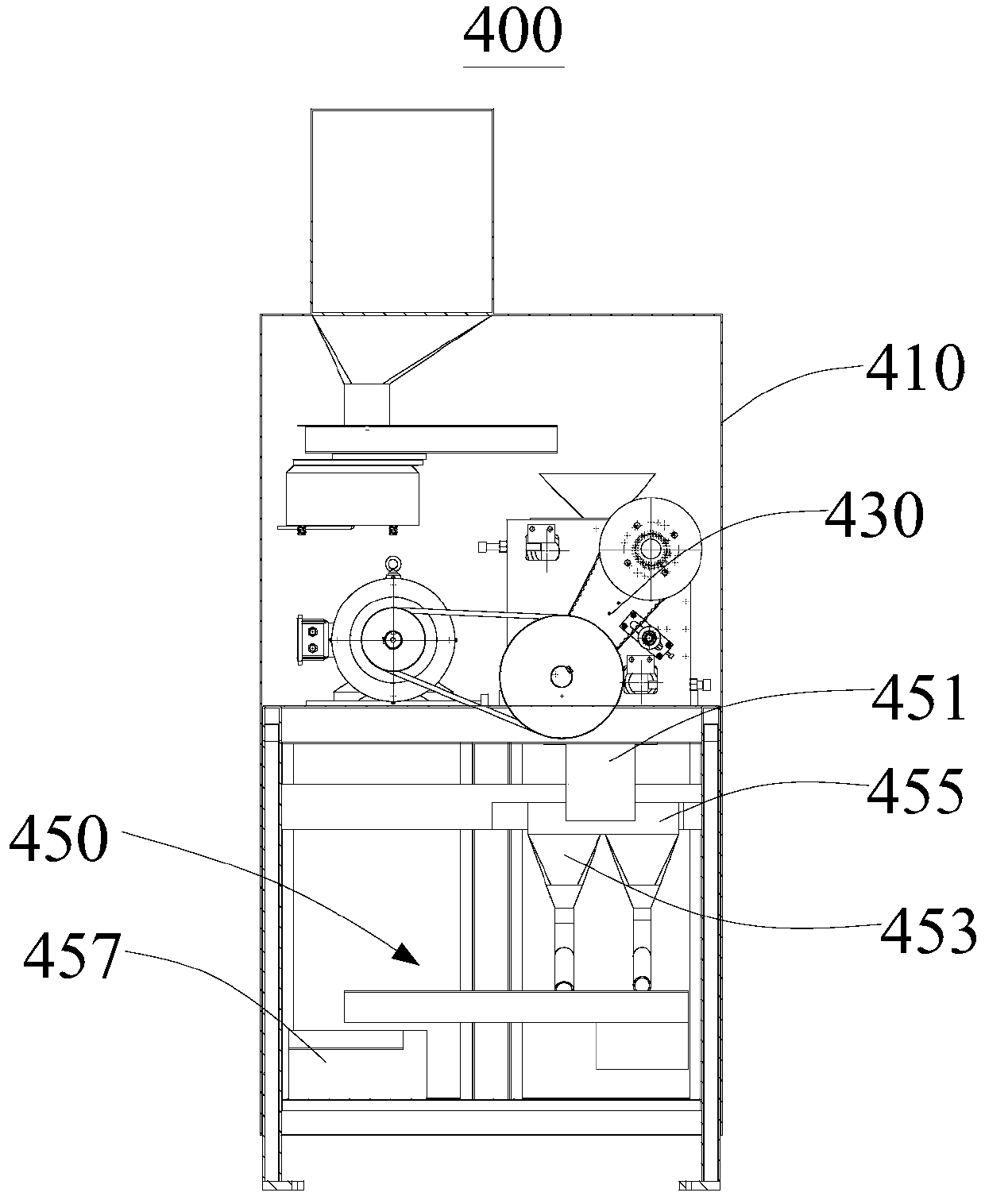

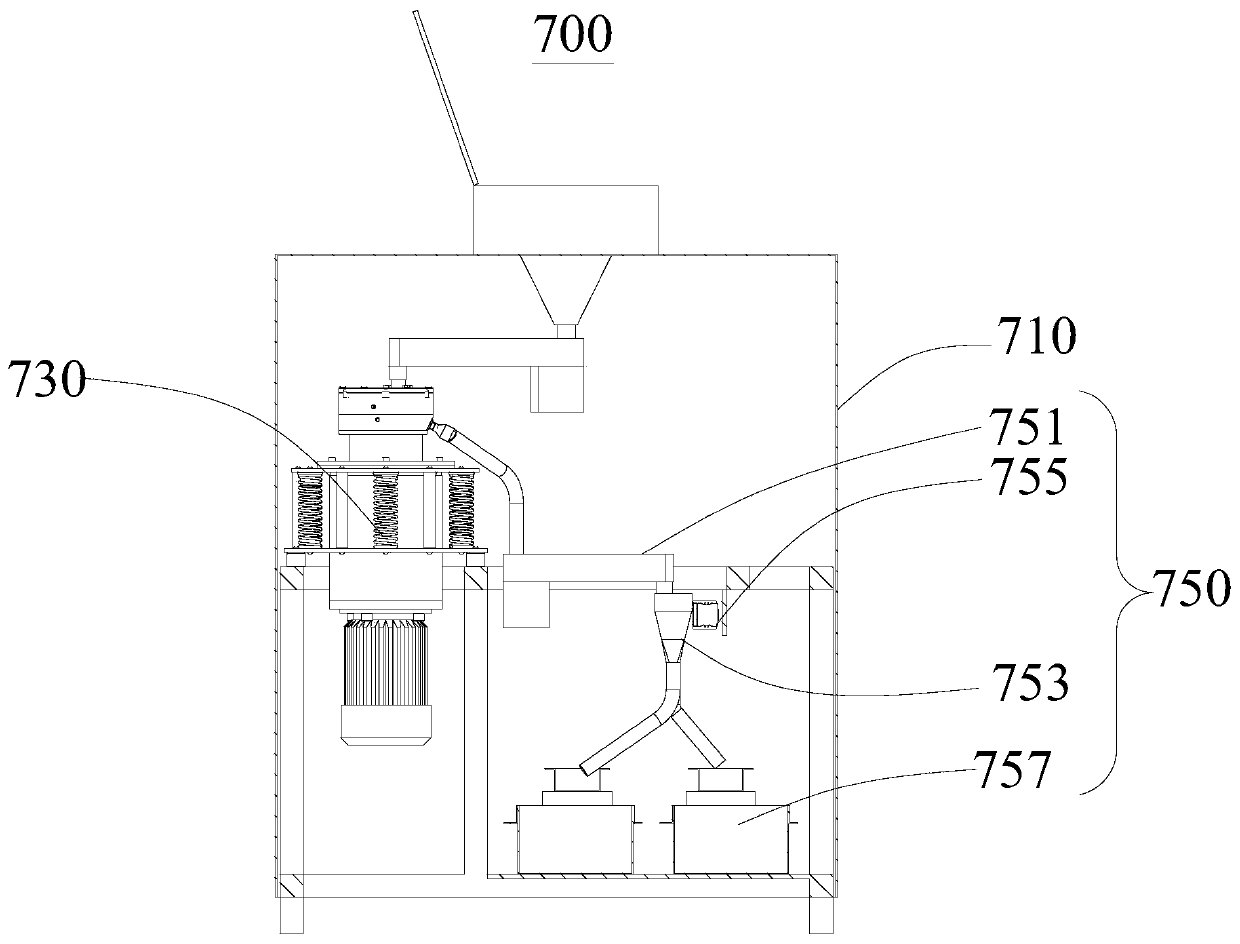

[0032] see figure 1 , the present embodiment provides a raw material sample preparation system 10, including a first material sampling device 100, a second material sampling device 200, an orbital robot 300, a crushing and shrinking machine 400, a powder ore shrinking and dividing machine 500, a moisture monitoring device and Grinding and shrinking machine 700; orbital robot 300 is slidably arranged on a sliding track, and orbital robot 300 can slide along the sliding track and extend into the first material picking device 100, the second material picking device 200, the crushing and shrinking machine 400, Fine ore shrinking and dividing machine 500, moisture monitoring device and grinding and dividing machine 700; the first material mining device 100 and the second material mining device 200 are arranged at intervals and facing each other, and are used to provide primary raw materials; the crushing and dividing machine 400 is arranged in the first mining Between the material de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com