Novel girder type gas injection packing support

A technology of gas injection and packing support, applied in chemical/physical/physical-chemical process, chemical instrument and method, chemical/physical process, etc., can solve the problem of insignificant support strengthening effect, unfavorable liquid redistribution, liquid storage or particle accumulation and other problems, to achieve the effect of improving strength and stiffness, reducing deformation, and preventing aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

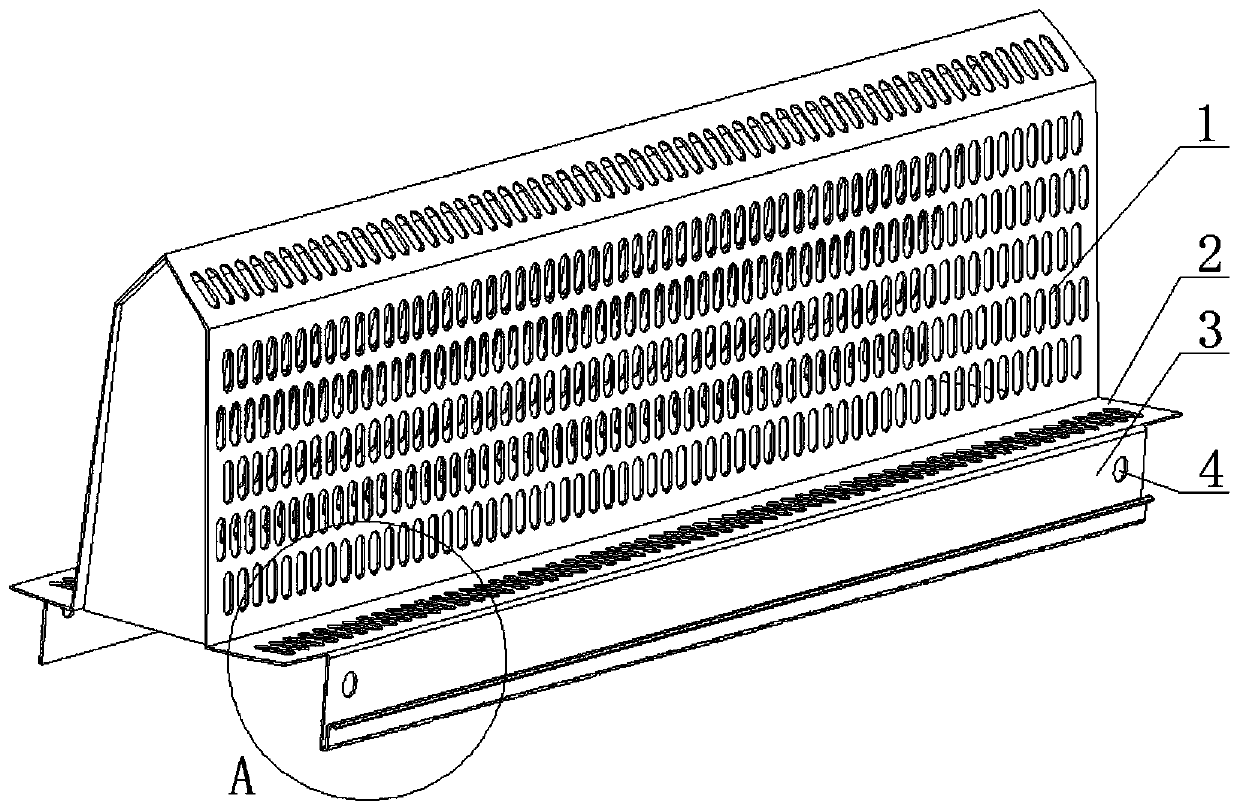

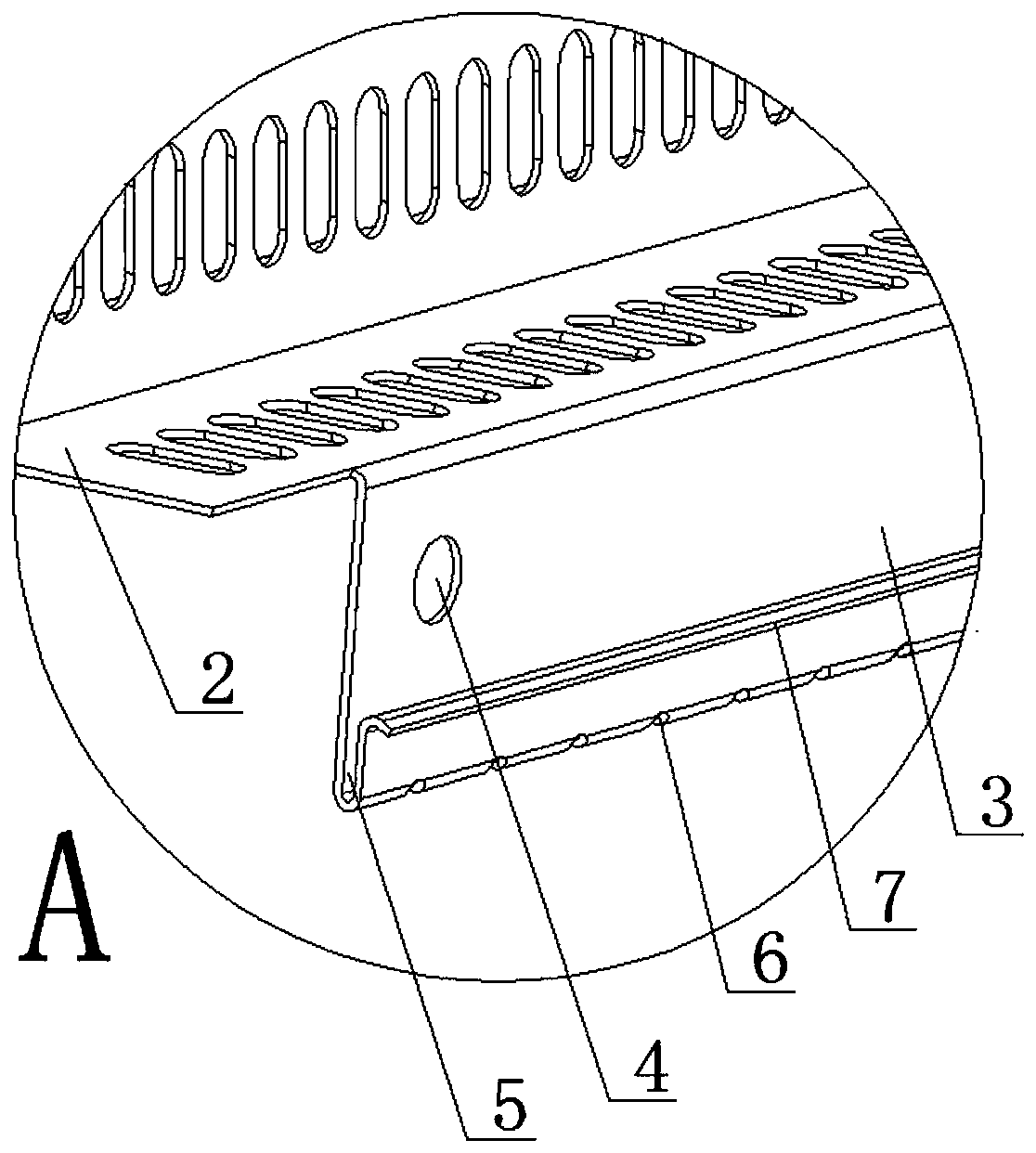

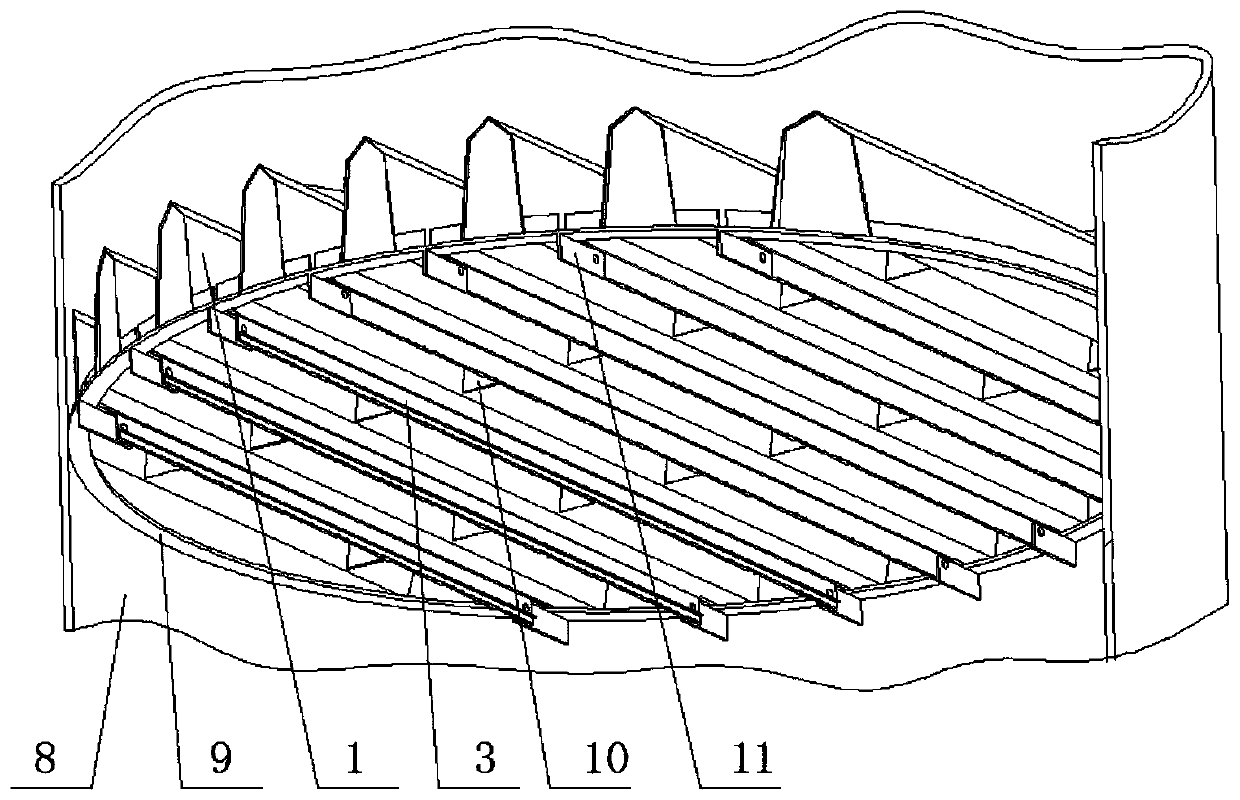

[0025] A new type of beam-type gas injection packing support unit, such as figure 1 , 2 As shown, it includes a hump plate 1, a support plate 2, and a connecting plate 3. The bottom of the hump plate is bent outwards along the horizontal direction to form a supporting plate, and the supporting plate is then bent downward to form a connecting plate. The connecting plate is perpendicular to the supporting plate. As required, the lower edge of the connecting plate is bent upward to form a slot 5 . In order to facilitate the liquid in the slot to flow out, a plurality of liquid guide holes 6 are evenly spaced at the bottom of the slot. In order to increase the strength of the slot, the upper edge of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com