Continuous bearing grinding device

A continuous and bearing technology, applied in the field of bearing processing, can solve the problems of low grinding efficiency and inability to continuously grind bearings, and achieve the effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

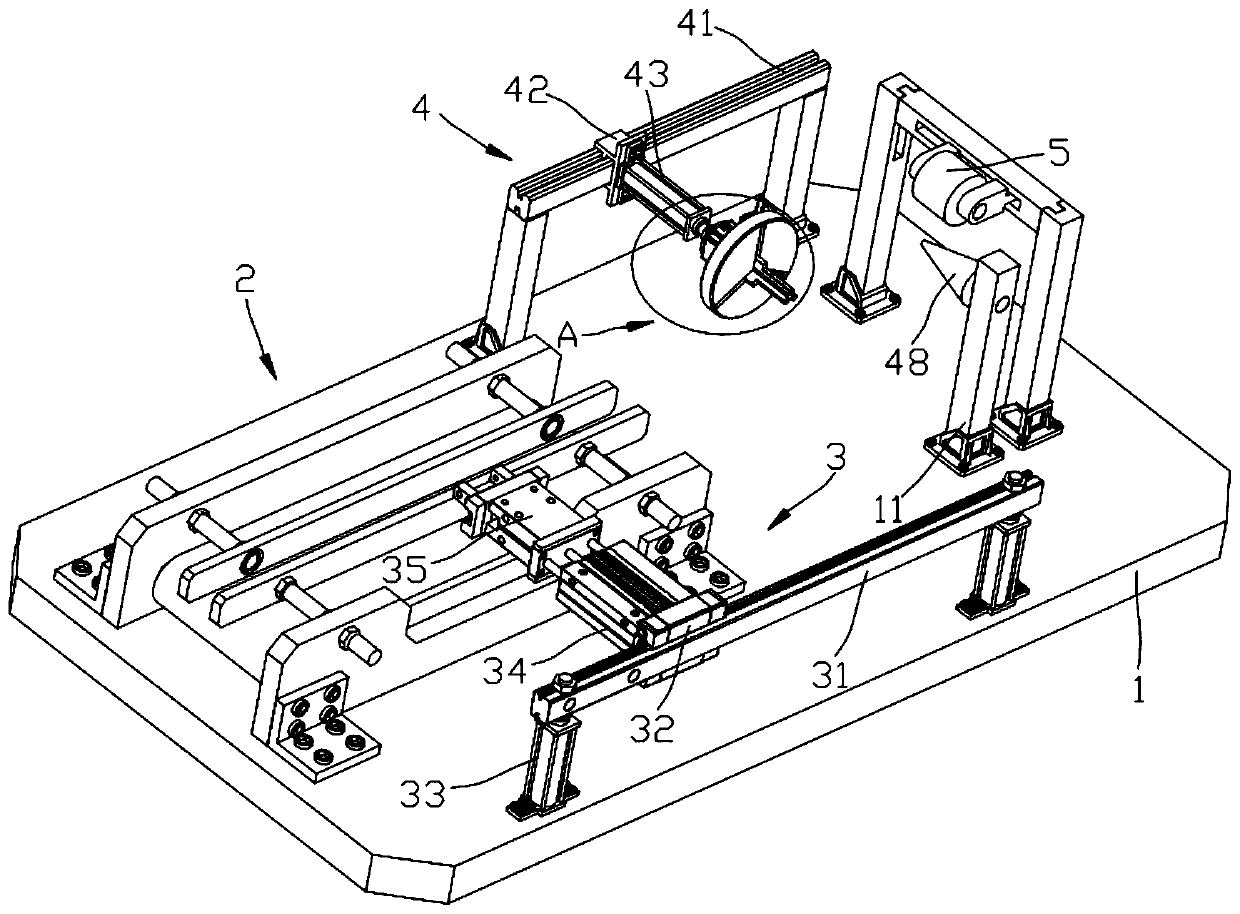

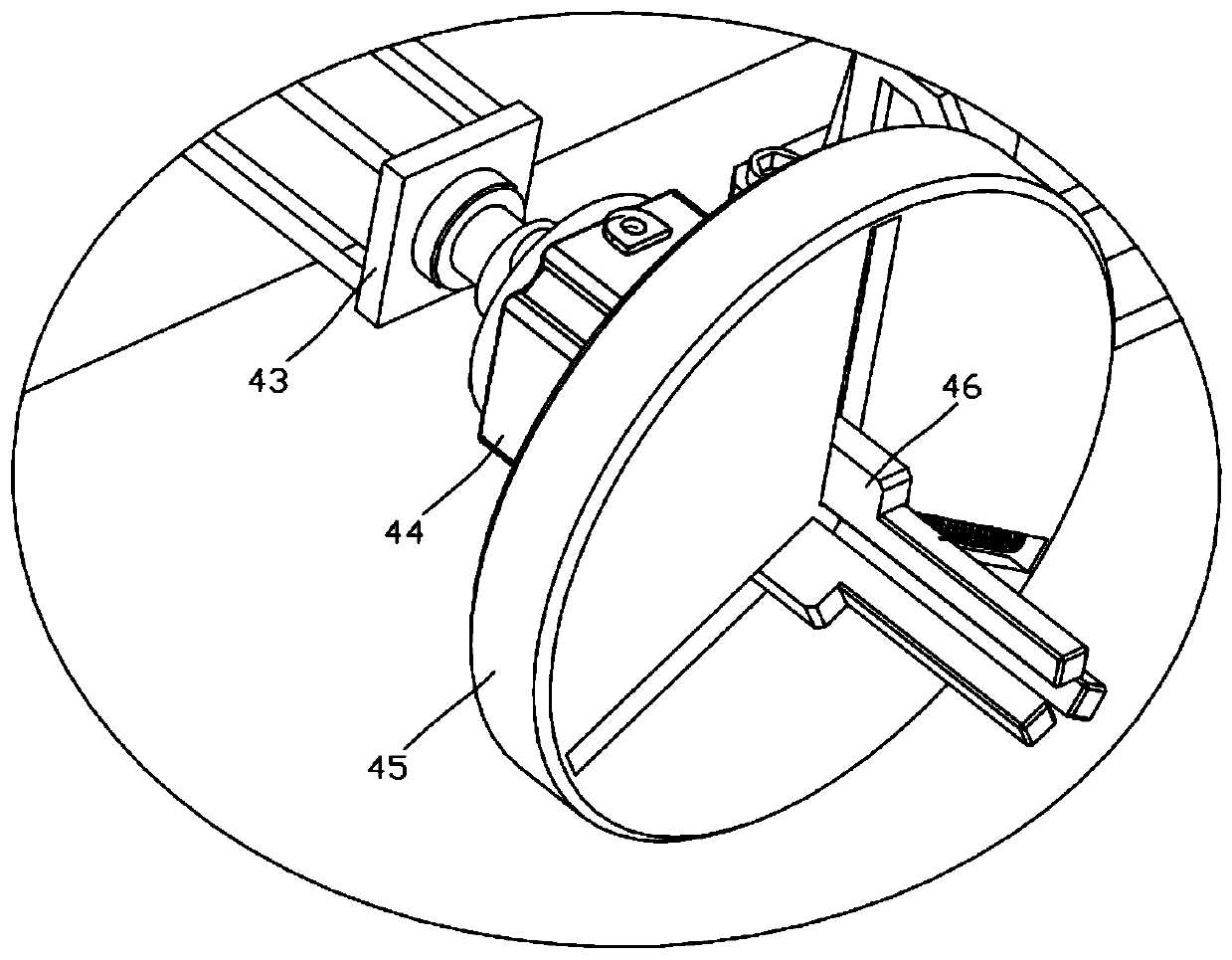

[0024] see Figure 1 to Figure 5 , the present invention provides a technical solution:

[0025] A continuous bearing grinding device, comprising a bottom plate 1, a feeding mechanism 2, a conveying mechanism 3, a grinding mechanism 4 and a grinder 5, wherein:

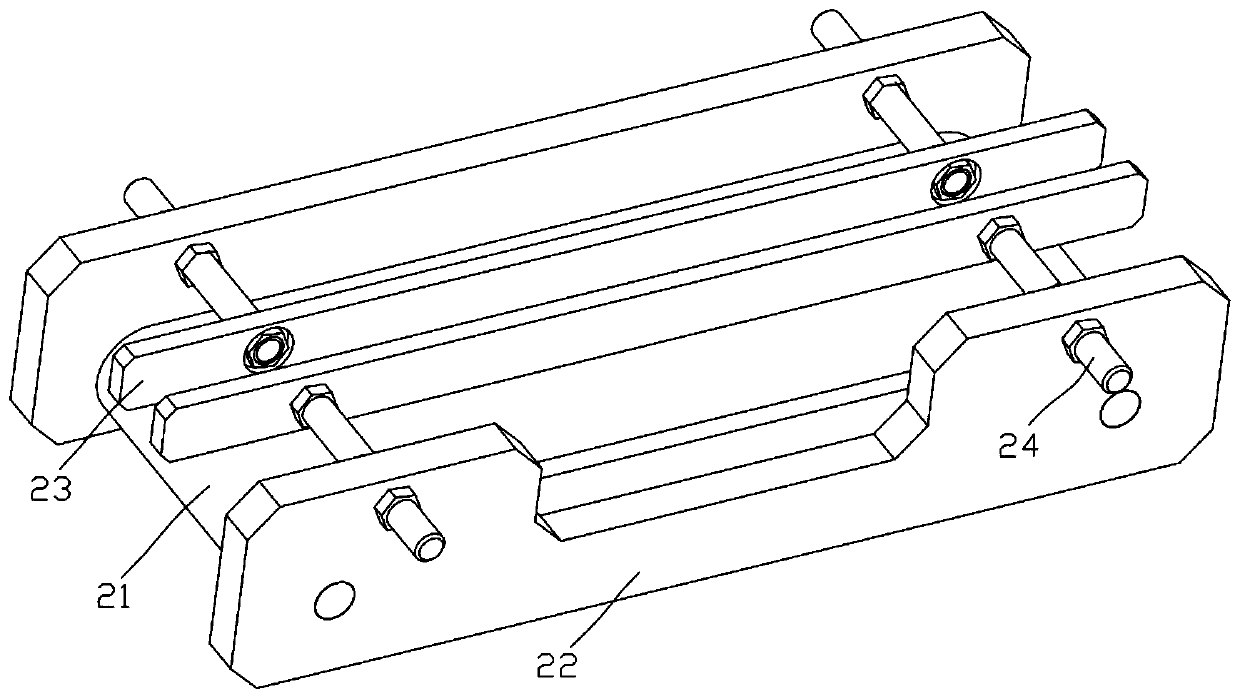

[0026] Feeding mechanism 2 comprises conveyer belt 21, side plate 22, baffle plate 23 and screw rod 24, and the two ends of conveyer belt 21 are respectively installed on two side plates 22 by bearing, and two side plates 22 are fixedly installed on respectively by mounting plate. On the bottom plate 1, two of the baffles 23 are placed opposite to each other on the bottom plate 1, and four screw rods 24 are movably installed on the two side plates 22 in pairs, wherein the screw rods 24 pass through the baffle plate 23 and are in contact with the baffle plate 23 A nut is provided, and the contact surface between the screw rod 24 and the side plate 22 is also provided with a nut;

[0027] The conveying mechanism 3 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com