Plate surface polishing device and processing method thereof

A technology of surface polishing and plate, which is applied in the field of plate processing, can solve the problems that some parts cannot be polished normally, affect the surface smoothness of the position, etc., and achieve the effect of convenient replacement of polishing abrasive cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

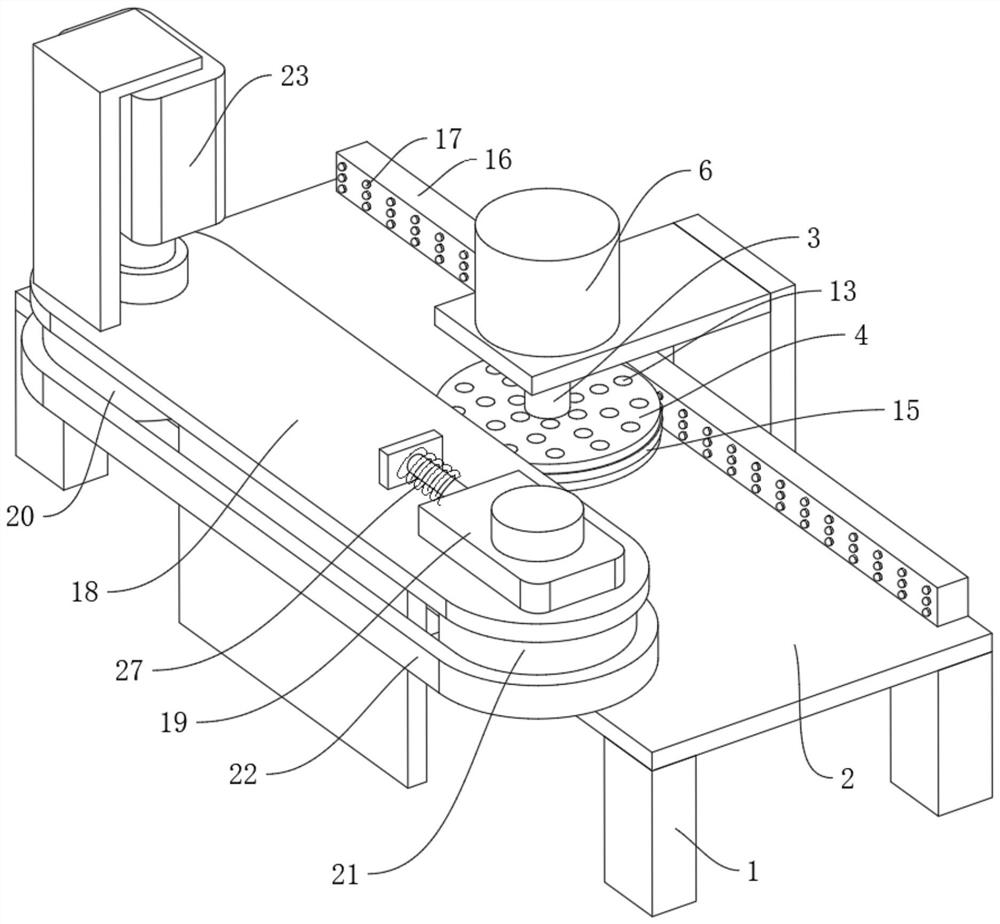

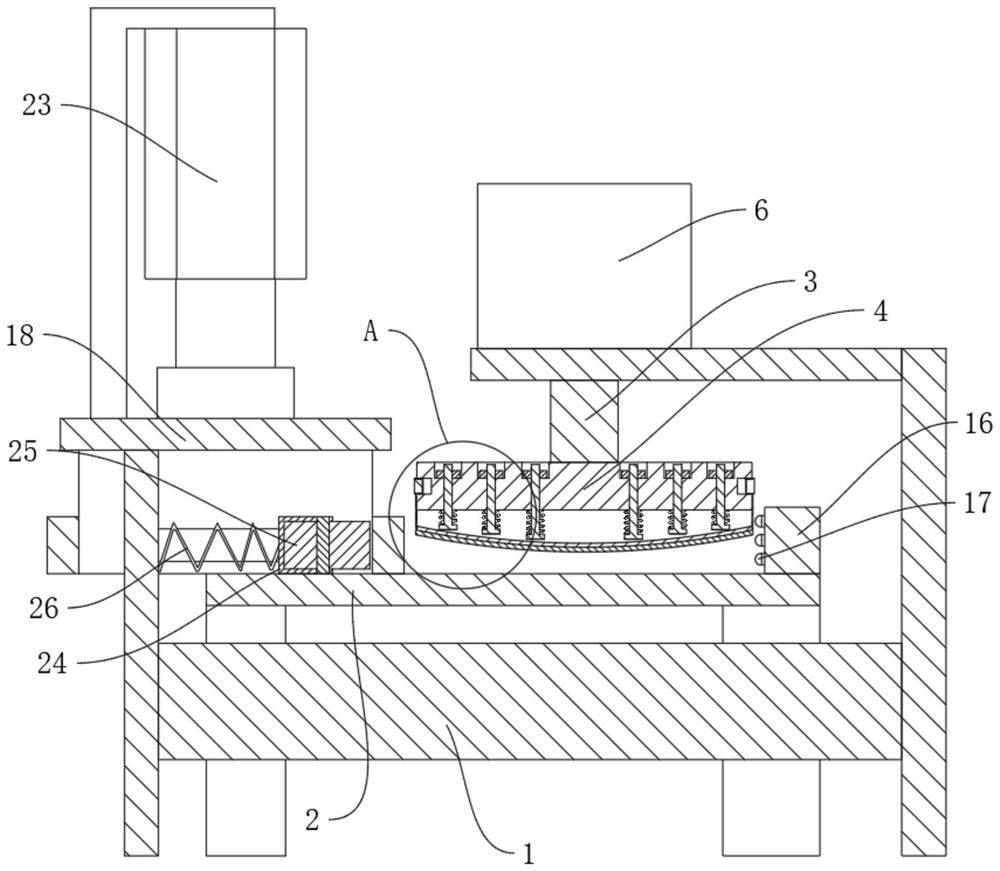

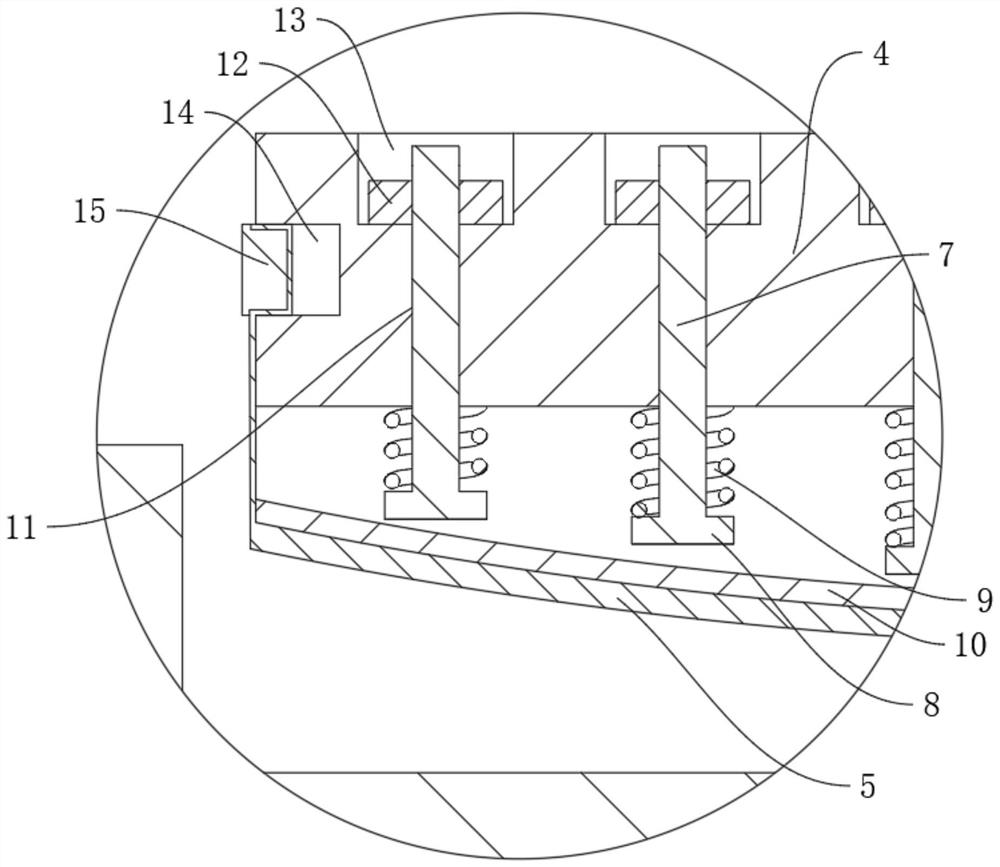

[0028] Embodiment 1: as Figure 1 to Figure 5 As shown, a plate surface polishing device proposed by the present invention includes a frame 1, the frame 1 is provided with a conveying platform 2 for the plate to move, and the frame 1 is provided with a drive for clamping and driving the plate to move Components, a polishing mechanism for polishing the surface of the plate, the polishing mechanism includes a polishing shaft 3 connected to the frame 1 in a vertical rotation, a polishing table 4 arranged on the lower end surface of the polishing shaft 3, and a polishing table 4 arranged on the polishing shaft 3. The polishing emery cloth 5 under the table 4 and attached to the surface of the plate, the driving motor 6 arranged on the frame 1 and driving the polishing shaft 3 to rotate, is arranged on the polishing table 4 and drives the polishing emery cloth 5 to abut against the surface of the plate structure, the polishing table 4 is provided with a detachable structure for con...

Embodiment 2

[0033] Embodiment 2: a kind of processing method utilizing the plate surface polishing device described in embodiment 1, has the following steps:

[0034] Step 1. Place the plate to be processed on the conveyor table 2 and push the plate between the driving belt 22 and the backing block 16;

[0035] Step 2, the driving belt 22 and the backing block 16 clamp the plate, the rotating motor 23 drives the driving belt 22 to rotate, and drives the plate to move synchronously towards the polishing table 4, when the plate enters between the driving belt 22 and the backing block 16, the plate and the backing block 16 An interaction force is generated between the push plates 24, and the push plate 24 is moved away from the mountain direction to a certain position, and the tension spring 27 drives the driven shaft 21 to move away from the direction of the driving shaft 20, so as to keep the drive belt 22 in a tensioned state, and Make sure that the board is attached to the backer block 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com