Automotive tire production technology system

A production process and technology for automobile tires, applied in tire installation, tire parts, vehicle parts, etc., can solve the problems of low efficiency, large manual handling workload, high labor intensity, etc., achieve good application prospects, and save time in production and assembly Effort-saving and highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

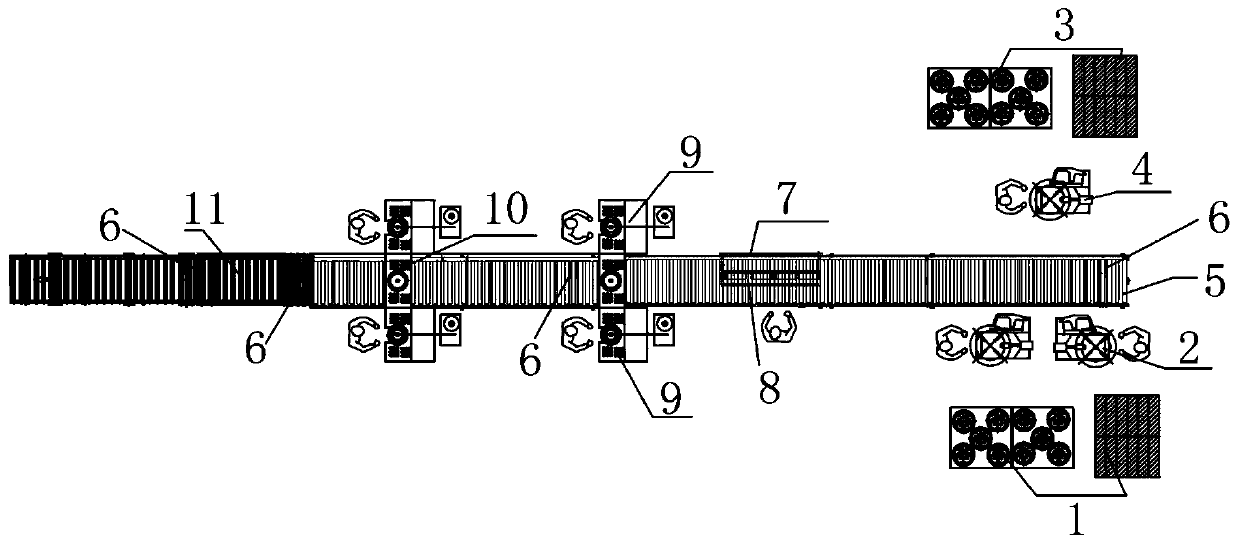

[0020] This automobile tire production process system of the present invention, as figure 1 As shown, there is a main tire assembly line 5 for transporting and assembling tires, and a main tire loading machine 2 and a spare tire loading machine 4 are respectively arranged on both sides of the starting end of the main tire assembly line 5, and a tire loading machine 4 is provided in sequence on the conveying direction of the main tire assembly line 5. With the inflation station 8 for inflating the tire and the dynamic balance detection device for detecting the dynamic balance of the tire, the end of the main tire assembly line 5 is connected 11 to the tire transmission line through the transition section, and enters the production line for assembly. The automobile tire production process system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com