Parallel compression co2 car heat pump air conditioning system with heat recovery device

A heat pump air conditioner, compression technology, applied in vehicle components, transportation and packaging, air handling equipment, etc., can solve problems such as poor heating performance, and achieve the effect of improving performance, efficient operation, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

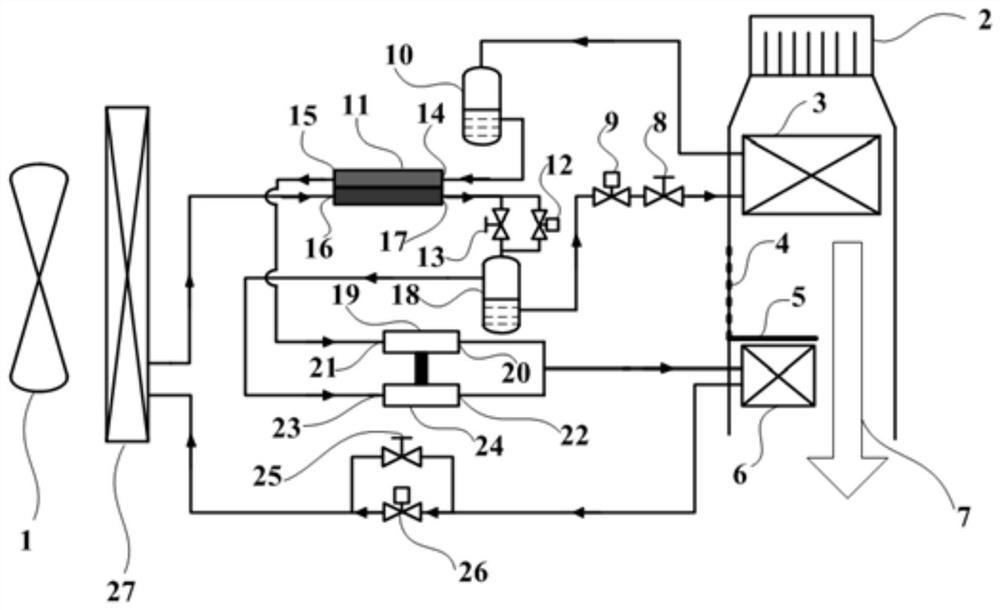

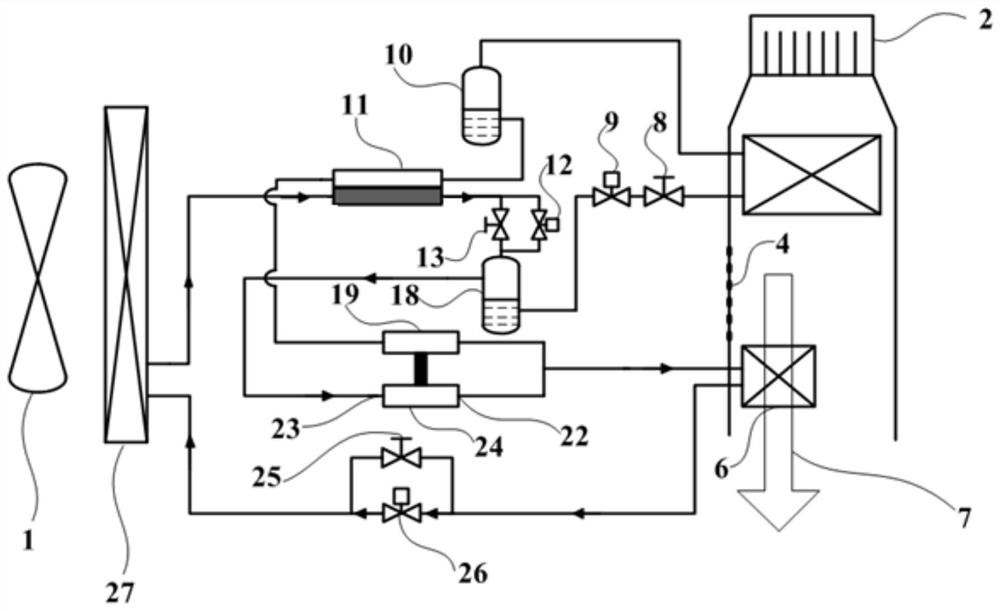

[0016] like figure 1 As shown, this embodiment includes: two parallel scroll compressors 19 and 24 connected coaxially, a gas cooler 6, an outdoor heat exchanger 27, an intermediate heat exchanger 11, a gas-liquid separator 18, an evaporator 3 and The liquid storage tank 10, wherein: the outlet 20 of the first scroll compressor and the outlet 22 of the second scroll compressor are connected to the input end of the gas cooler 6, and the output end of the gas cooler 6 is exchanged with the middle through the outdoor heat exchanger 27 The high-pressure input end 16 of the heat exchanger 11 is connected, the high-pressure output end 17 of the intermediate heat exchanger 11 is connected with the input end of the gas-liquid separator 18, and the gas output end of the gas-liquid separator 18 is connected with the second scroll compressor inlet 23 , the liquid output end of the gas-liquid separator 18 is connected to the evaporator 3 and the liquid storage tank 10 in turn, the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com