Tempered glass and manufacturing method thereof

A technology for strengthening glass and manufacturing methods, applied in the direction of coating, etc., can solve the dilemma of overall strength and safety, and cannot reach the maximum strength, etc., and achieve the effect of strong safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The method for preparing strengthened glass provided by the present invention mainly includes the following steps:

[0039] Step S1: coating a high temperature resistant protective coating on a part of the glass to be strengthened, and curing the protective coating;

[0040] Step S2: putting the glass to be strengthened into a first ion exchange salt bath for chemical strengthening;

[0041] Step S3: taking out the glass to be strengthened from the first ion exchange salt bath, and cleaning the glass to be strengthened;

[0042] Step S4: removing the protective coating on the glass to be strengthened.

[0043] Because the protective coating in step S1 can prevent or impede ion exchange in the first ion exchange salt bath in the partial region of the glass to be strengthened. Therefore, after the above steps, the depth of the ion exchange layer in the part of the glass to be strengthened must be smaller than the depth of the ion exchange layer in other parts of the gla...

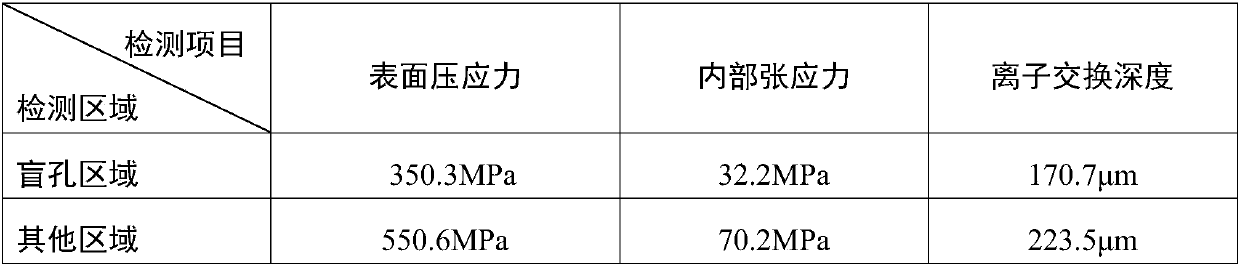

Embodiment 1

[0048] Prepare a sheet of glass to be strengthened with a blind hole in the middle, the thickness of the blind hole area of the glass to be strengthened is 2.1mm, and the thickness of other areas of the glass to be strengthened is basically 2.2mm (error less than 0.04mm).

[0049] Then the glass to be strengthened is processed as follows:

[0050] Step S1, coating the protective coating a on both sides of the blind hole and its surrounding area of 5 mm, the protective coating a is required to cover the entire blind hole and the area within 5 mm around the blind hole, and the blind hole The thickness of the protective coating a on the inside of the front is about 35-40 μm, and the thickness of the protective coating a on the back of the blind hole is 15-20 μm, and the protective coating a is cured under certain conditions.

[0051] Step S2, putting the glass to be strengthened into an ion-exchange salt bath a at 420° C. for 120 minutes.

[0052] Step S3, taking out the gla...

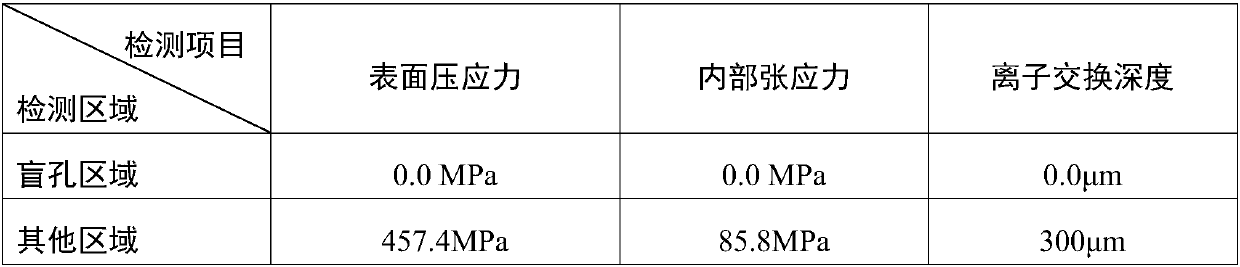

Embodiment 2

[0077] Its difference with embodiment 1 only lies in:

[0078] First, in step S2, the glass to be strengthened is placed in an ion-exchange salt bath a at 430° C. for 180 minutes.

[0079] In addition, protective coating b is used instead of said protective coating a. In this embodiment, the difference between the protective coating b and the protective coating a is that the glass 8206 powder is used instead of the glass 8205 powder, wherein the preparation process of the glass 8206 powder is as follows:

[0080] (1) Take the raw materials of each mass ratio according to the formula of each raw material content in the following table, mix and stir evenly;

[0081] raw material

B 2 o 3

ZnO

TiO 2

ZrO 2

Al 2 o 3

MgO

SiO 2

Mass ratio (%)

3.7

4.5

2.3

3.5

11

10

65

[0082] (2) Put it into a crucible and heat it to above 1300°C to make the glass into a molten state;

[0083] (3) Quenching the molte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com